hsems - Arizona Environmental Strategic Alliance

advertisement

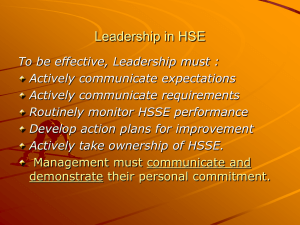

14-Jan-2014 Honeywell Aerospace Management System Approach HSEMS Overview & SBG Governance Gregory A. Bopp, CHMM Director, HSE&F Compliance Assurance Honeywell Aerospace Honeywell.com Gregory A. Bopp, CHMM Director, HSE&F Compliance Assurance Honeywell Aerospace, Phoenix AZ • 25-years HSE experience with Multi-National Corporations – Lighting and Electronics- Lighting, Ballasts, Transformers, Magnet Wire – Consumer Packaging – Coated Films/Papers, Beverage Cans, Glass, Plastics – Aerospace– Auxiliary Power Units, Engines, Brakes, Avionics • Geographical Work Experience: – USA, Canada, Mexico, Brazil, Chile, Argentina, UK, France, Germany, Czech Republic, Italy, China • Technical Body of Knowledge – BSChE, University of Illinois – Air Emissions Control, Industrial Waste Water Treatment, Chemical Substitution, Plating, Cleaning Technology, Industrial Property Remediation, Environmental Site Assessments, ISO 14001, ISO 18001, RCRA, OSHA, DOT, FAA, NFPA 2 Document control number Honeywell Proprietary Aero HSE&F Vision and Mission Vision Integrated business partner providing unparalleled HSE&F value and uncompromising commitment to employee health and safety and environmental stewardship. Mission Protect people and the environment through the capabilities of our global talent and the strength of our HSE & Facilities Management Systems. HOS Identified as the Means to Deliver on Vision and Mission 3 HSEMS Framework 4 HSE Management System Defined • An HSEMS: - Creates standardized and formal activities to identify and prioritize HSE risks - Establishes effective controls for priority risks - Assigns responsibility and accountability - Monitors and drives continuous performance improvement Standardization, Efficiency, & Continuous Improvement 5 Importance of Management Systems Objectives & Expectations (by setting these) Where & Why Feedback Mechanisms (continuous improvement) How to Improve Performance Metrics (measure results) How HSEMS How Well Who Key Steps & Requirements (procedures) Resources (identifies who is responsible) Effective HSE Management Critical to Success 6 Honeywell Is Committed to Success • Honeywell’s Sustainable Opportunity Policy: - Communicates Honeywell Leadership’s commitment and expectations - Establishes the framework and guidance for HSE performance standards, strategic planning, objectives and targets, and the HSEMS Provides the Framework for the HSE Management System 7 Aerospace HSE Management System • Defines operations Policy Management Review Risk Assessment • Engages leadership Objectives & Targets • Applies responsibility and accountability • Monitors legal and other Legal & Other… Environment Product Stewardship Safety Monitoring, Measurement… Structure & Responsibility HSEMS requirements • Prioritizes HSE risks Corrective & Preventive Action Loss Prevention Health Document Control… • Links standards • Involves continuous cycles of feedback Industrial Hygiene Operational Control Communication Training Management of Change A Mature Management System Enables Sustained HSE Compliance 8 Aero HSE Management System • Risk Assessment • Management of Change • Legal and Other Requirements • Monitoring, Measurement, and Self Assessment Risk Management • HSE Policy • Structure and Responsibility • Objectives, Targets, and Management Plans • Management Review Risk Assessment Leadership A systematic, continuous cycle of activities… • Training • Communication • Operational Control • Document Control and Records • Corrective and Preventive Action Components and standards are linked Drive HSE Performance 9 HSEMS Participants HSEMS Standard Sponsor Standard Owners Other Resources Typically site leadership team representative Responsibilities: 10 Example tasks: • Champion standard implementation, maturity and leadership engagement • Site Leader could sponsor identified standards and committees • Allocate resources for standard development, implementation and maturity • Site Leader fosters understanding of the Policy, signs the Policy, and communicates the requirements to the Site Leadership Team HSEMS Participants HSEMS Standard Sponsor Standard Owner Other Resources The person positioned to effectively execute implementation. Responsibilities: • Administer the standards on a day-to-day basis • Identify resources needed for implementation Logical Owners: • Engineering or Operations: Management of Change • Operations: Preventative/Corrective Actions • HR: Communications 11 HSEMS Participants Standard Sponsor Standard Owner Site HSE Personnel and Aero HSE&F Leadership • Support integration of standard requirements • Develop and steward overall site HSEMS implementation • Facilitate overall coordination and networking among location HSEMS standard owners • Serve as a single point of contact for external HSEMS communications 12 Other Resources • Human Resources, HSE, Facilities, Legal staff that support and ensure effectiveness of the standards • Provide subject matter expertise HSEMS Steering Committee • Assures HSEMS implementation and continuous improvement remains a priority • Sets HSEMS goals and objectives for the location • Approves, commits or obtains resources with the requisite knowledge, skills and expertise for systems development, implementation, maintenance and assessment • Assures responsibility, accountability and authority for all HSEMS standards • Approves location’s HSEMS Management Program, including significant plan changes (Objectives, Targets, and Management Plans) Responsible and Accountable Resources 13 Aspects Critical to Success • Align Standard Sponsors and Owners with activities • Communication between Standard Owners and Sponsors both internally and externally • Standard Sponsors should be: - Members of the location’s Leadership Team - Actively involved to assure resources are adequate and barriers are addressed in a timely manner • Active Management Review - Ensures HSEMS is well integrated - Effectively prioritizes implementation and improvement plans 14 HSEMS Standards Overview 15 HSE Policy (Sustainable Opportunity Policy) • Communicates Honeywell-wide Leadership commitment to and endorsement of HSE expectations • Establishes the framework and guidance for HSE performance and behaviors • Is made visible to the global workforce, contractors, stakeholders and public Clear, Concise, and Communicated Commitment 16 Risk Assessment • Systematic identification of HSE hazards and risks • Defines, evaluates, prioritizes, and controls operational risk • Facilitates risk reduction and implementation of abatement actions within location’s “scope” Produces Risk Profile – Prioritizes Significant Risk 17 Legal and Other Requirements • Requires identification and assessment of legal & other requirements • Enables visibility to and understanding of: - Existing legal and regulatory requirements - New and pending legislation - Non-regulatory requirements imposed on or committed to by the organization - Current compliance status and risk to compliance Reliable Understanding of Requirements 18 Structure and Responsibility • Links responsibility and accountability to Site Leader • Establishes framework for development of clear HSEMS roles & responsibilities • Incorporates HSE performance expectations in the performance management process • Defines behavior and culture performance expectations Defines Responsibility & Accountability 19 Document Control and Records • Establishes and implements a process which assures effective management of HSE documents and records • Assures current versions of HSE documents and records are readily available • Establishes document review process expectations • Designates individuals responsible for the maintenance and review of HSE documents and records Standardizes Documentation And Controls Records 20 Operational Control • Identifies, develops and implements operational controls for HSE risks • Assures operational controls reduce or abate risk • Assures operational controls are communicated to affected personnel • Analyzes preventive and corrective actions to assess operational control effectiveness Control Standards Are Put In Place 21 Management of Change • Establishes a proactive process for risk assessment & management during the introduction of new products, materials, equipment and facilities • Assures changes and/or modifications comply with existing legal and other requirements • Identifies, evaluates and controls HSE risks associated with change Linking HSE Practices Into Processes 22 Training • Identifies and documents training requirements • Assures development and implementation of training programs to meet the training needs assessment • Evaluates training effectiveness Shaping Behaviors & Developing Employees 23 Communication • Assures effective management of internal and external HSE communications • Defines HSE communication strategies and develops location-specific, documented processes • Engages leadership and all organizational levels in two-way HSE communications Communicate, Communicate, Communicate… 24 Corrective and Preventive Action • Establishes methods to address and investigate potential or actual non-conformance • Establishes effective Root Cause Analysis methodologies • Prioritizes and tracks corrective and preventive actions • Analyzes corrective and preventive actions for system improvement opportunities Systematic Approach To Manage HSE Defects 25 Monitoring, Measurement and Self-Assessment • Monitors and measures HSE activities and performance on a regular basis • Ensures significant HSE risks are being controlled • Enables evaluation of detection and correction programs • Identifies weaknesses to prevent HSE incidents Auditing To Ensure Compliance 26 Objectives, Targets and Management Plans • Provides guidance and requirements to facilitate establishment of HSE objectives and targets • Places focus on critical HSE opportunities and risks • Facilitates continuous improvement of HSEMS • Establishes formal plans to achieve objectives & targets Focused HSE Improvement Efforts & Resources 27 Management Review • Enables regular review of HSEMS • Engages leadership to evaluate, manage and continually improve the HSEMS • Integrates into the existing business review processes • Sets the stage for future actions and activities Leadership Engagement 28 Linkage Lessons Learned • Linkage is important in the design of the system • Linkage is essential in the implementation of the system • Examples of The Missing Link… - Objectives & Targets not tied to significant risks - Structure & Responsibilities not tied to Management Plans - Training content not tied to Management Plans • Self-assessment must examine linkage effectiveness Eliminate the Missing Link 29 Summary • Continuous cycle of standardized and formal activities to identify and prioritize HSE risks • Predictive performance through risk profile management • Establishes effective controls for priority risks • Assigns responsibility and accountability • Monitors and drives continuous performance improvement • Comprehensive and standardized performance standards • Documented leadership commitment • Formal, integrated programs • Robust HSE governance program HSEMS drives proactive…disciplined HSE culture Questions 31