COSL Drilling Europe

advertisement

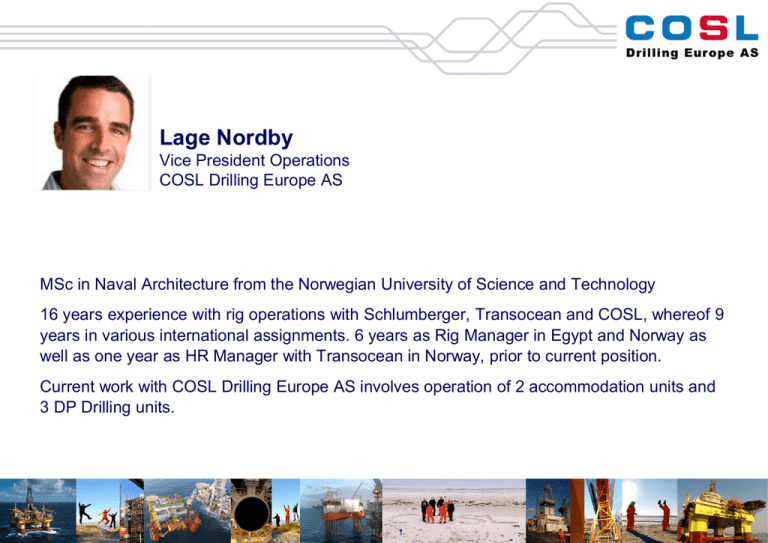

Lage Nordby Vice President Operations COSL Drilling Europe AS MSc in Naval Architecture from the Norwegian University of Science and Technology 16 years experience with rig operations with Schlumberger, Transocean and COSL, whereof 9 years in various international assignments. 6 years as Rig Manager in Egypt and Norway as well as one year as HR Manager with Transocean in Norway, prior to current position. Current work with COSL Drilling Europe AS involves operation of 2 accommodation units and 3 DP Drilling units. 1 NFLB 15.03.2013 www.cosl.no COSL Drilling Europe Building a rig (and it’s challenges) Operations Competence and capacity 3 COSL – China Oilfield Services Limited China National Offshore Oil Corporation CNOOC 45.28% 29% Public Public 54.72% CNOOC China Oilfield Services Limited Core Business Oilfield Services 2011 71% CNOOC 32% Public 38.42% 59.41% CNOOC Promoters 2.17% China BlueChem Limited CNOOC Limited Core Business Core Business Petro-Chemical E&P 4 Public 68% CNOOC Offshore Oil Engineering Co. Ltd. Core Business Offshore Engineering COSL DRILLING EUROPE AS 3 + 1 Semi submersibles COSLPIONEER 2 +2 years Statoil COSLINNOVATOR 8 + 8 years Statoil COSLPROMOTER 8 + 8 years Statoil COSLPROSPECTOR (Under Construction) 8 Jack Ups Operated by Singapore office COSL Drilling Europe 2011 5 2 Acc units COSL RIVAL - ConocoPhillips COSLRIGMAR - ConocoPhillips CDE Management team 6 People Employees 01.03.2013 Total Offshore Onshore Forus/Mongstad Yantai 775 625 150 110 45 15 apprentices 10 subsea trainees 3 students (MSc/BSc engineers) Approx. 16000 applications 40% with relevant competence 30% with relevant competence and experience COSL Simulator at SOTS in Stavanger 7 Activities COSLRival COSLRigmar COSLPioneer COSLInnovator COSLPromoter COSLProspector Accomodation – 360 COPUK - Judy Accomodation – 326 COPNO - Eldfisk Driling/Completion Statoil – FastTrack Driling/Completion Statoil –Troll Driling/Completion Statoil – Troll Under Contruction ? 8 Operations concept Mongstad Supply Centre COSLRIGMAR COSLPROSPECTOR COSLPIONEER COSLINNOVATOR COSLPROMOTER 9 COSLRIVAL COSL DP3 Drilling Rig (GM4000) MADE IN NORWAY NOV Drilling equipment Kongsberg DP & Navigation Molde cranes 80 T, 20m RR anker Winches 2 X Norsafe MAKO 655 Diesel jet 4 X Norsafe GES 40 Lifeboats Simens/ ABB switch boards 6 X Wärtsila Diesel engines/ W12V32 6 X Siemens Generators 6 X Wärtsila LIPS Azimut Thrusters MADE IN CHINA… 10 11 11 Building a Rig www.cosl.no New and unique way of constructing drilling rigs Ref.: 90357 5/2/201328/9/2010 Mating of Pioneer Ref.: 64812 6 Building a rig The requirements 15 Flag – MPA (Singapore) IMO MODU Code ISPS Code ISM Code MARPOL International Convention on Load Line ILO 92/133 – Accommodation International Convention on Tonnage Measurement of Ships 16 Petroleumstilsynet / bistandsmyndigheter Andre bistandsmyndigheter Approx 2800 requirements Approx. 1300 are relevant 17 Class (DNV) + «Overlappende regelverk» Drilling utstyr OS-E101 Helidekk: OS-E401 Sikkerhet OS-A101 OS-D301 Kraner Ship Rules Part 6 Ch.2 Sec.3 Stål/struktur OS-B101 OS-C101 OS-C103 OS-C-401 RB-B401 RP-C103 RP-C201 RP-C202 RP-C203 RP-C204 Marine/Maskin OS-D101 Elektrisk OS-D201 Instrument OS-D202 Ship Rules: Part 6 Ch.3 (EO) Stabilitet OS-C301 Posisjonering OS-E301 Ship rules Part 6 Ch. 7 (DP) 18 Anvendelse av norsk offshore regelverk Helikopterdekk Sjøfart, Helikopter Dekk Drilling Utstyr Innretningsforskriften Boligkvarter Sjøfart, Boligkvarter Sjøfart, Drikkevann Innretningsforskriften Andre petroleums relaterte systemer/ utstyr Innretningsforskriften Kraner Sjøfart, Kran Sikkerhet/brann Sjøfart, Brann Sjøfart, Konstruksjon Sjøfart, Boligkvarter Arbeidsmiljø Sjøfart, Konstruksjon Innretningsforskriften Maritimt utstyr Sjøfarts regelverk Stål/struktur Sjøfart, Konstruksjon Livbåter og redningsfartøy Sjøfart, Livreddende anordninger Innretningsforskriften Stabilitet Sjøfart, Stabilitet Sjøfart, Ballast Posisjonering Sjøfart, Ankerhåndtering IMO 645 Forurensning Sjøfart og PTIL regelverk 19 Standarder, retningslinjer og anbefalinger NORSOK NORSOK standarder: ISO standarder: Boreutstyr, heiser, ergonomi, branndeteksjon, HVAC, m.m. Olf’s anbefalte retningslinjer: Arbeidsmiljø, boring, kran og løft, m.m. Kompetanse, beredskap, sikring, rørhåndtering, m.m. SfS anbefalinger: Arbeidstillatelse, Sikker Jobb Analyse, Fallsikring, Fallende gjenstander, m.m. 20 …..Sea Voyage Prep. Yantai Las Palmas-Norway 12 days Port Las Palmas 2 days Yantai-Singapore 13 days Port Singapore 4 days Namibia - Las Palmas 19 days Singapore-Mauritsius 16 days Port Mauritius 1 days Namibia(Walvis Bay) 1 days Mauritsius-Namibia 15 days (Average speed 8.5 knots) Ref.: 90357 5/2/201328/9/2010 Building a rig Arriving in the fjord 22 Rig Acceptance Why 7-8 months in the fjord? (COSLPioneer, 4 months) Technical challenges Rig completion Emergency Shut Down and Fire & Gas system Electrical installation quality Offshore acceptance BOP control system (LMRP disconnect) DP Stationkeeping - tuning Heave compensated Drawwork – tuning Vendors Delivery quality and understanding of requirements Capacity and availability of competance Client scope & acceptance process 3rd party scope Interpretation of requirements (Client vs Contractor) Acceptance Test Program – what to expect? Industry challenge Agree on requirements Achieve early clarifications Agreed acceptance requirements Focus the scope to critical activity Electrical Challenges Ex glands not installed correctly Action: Full check and retermination (all compartments on the rig) HV cables - wrong crimping LMRP disconnect Time to disconnect Water Depth 318 meters R I S 3 Deg E R LMRP BOP Corrective Actions: - Modification to BOP controls - Change og BOP fluid - Change out Valves and pipings NOV Active Heave Drilling Drawworks Water Depth 318 meters R I S E R LMRP BOP Kongsberg Motion Reference Unit - MRU Challange: -Incorrect settings for AHD Drawwork -Interface between MRU software and HCD software not syncronized Operation - how did it go? www.cosl.no Operations Key achievements Simplistic HSE focus – Statoil best practice COSLPioneer: «Rig of the month» after 8m Continuous strong operational performance COSLInnovator: 0.75 hrs dt first operating month How? Strong crew competance Rig familarization - structure QHSE / procedures made practicle Merge process Reduce paper Meet people in their work place Open and direct culture 28 Going forward.. Market competition for people COSLProspector = opportunities 2013 Operational focus Job Planning / Barrier Management Experience Transfer Common operating procedures Common practice for experience transfer Transfer Learnings to COSLProspector Maintenance/stock optimizing Keeping the COSL culture 29 Competence & Capacity www.cosl.no Personnel requirements 2013-2015 2700 personnel required to man 21 new entry drilling units Onshore management of 18-21 rigs 11% of personnel aged 61-70 yrs with the next 5 yrs 18-21 rigs require 3’party WL, ROV, CMT etc. Planning and preparation for new drilling campains Follow up from authorities Service personell from equipments manufacturars Courses and training 31 Training Requirements 32 Competence & Capacity Future challenges: Vendors ability to recruit and train new and competent service personnel. (Already stretched on both capacity and competence) Shipyards ability to recruit and train new and competent yard personnel. (Already stretched on both capacity and competence) Drilling contractors ability to recruit and train new personnel. (Will be a challenge in 2014 – 2015) Possible consequences: HSEQ ! Considerable delays if unplanned stop in operations ! Extensive delays in connection with modification projects, upgrades, SPS and new rigs ! 33 Competence & Capacity “Kilde www.offshore.no/ August 2012” 34 Service personell & equipment Limited access to competent service personnel Drilling Equipment, DP systems, electrical systems, engines and generators, thrusters, etc.. Long delivery of critical equipment BOP 26m Lifeboats 21m Drill pipe 8-9m 35 Do we have a challenge… 36 Now what?... Coordinated information to the industry on future requirements for resources and equipment Reduce use of resources for rig mobilization / acceptance Carefully evaluate initiatives, change of regulation, revisions and industry requirements Simplify training requirements Insanity: doing the same thing over and over again and expecting different results. Albert Einstein 37 Thank you 2011 Ref.: 89281 38