INDUSTRIAL APPLICATIONS OF WIRELESS SENSOR NETWORKS

advertisement

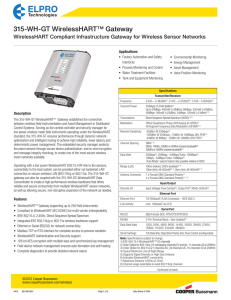

MENG584- Final Project Kian Jazayeri 105234 Fazel Farazandeh 105262 Introduction The aim of this study is to analyze the effect of applying wireless sensor network technology in industrial platforms and the corresponding technical difficulties and design goals. In following section, the specifications of two IWSN standards (Zigbee and WirelessHart) are compared. Finally a real case of applying IWSN in Oil and Gas industries which is considered as a continuous manufacturing platform will be discussed. A wireless sensor network (WSN) consists of spatially distributed autonomous sensors to monitor physical or environmental conditions, such as temperature, sound, vibration, pressure, motion or pollutants and to cooperatively pass their data through the network to a main location. The WSN is built of "nodes" – from a few to several hundreds or even thousands, where each node is connected to one (or sometimes several) sensors. Each such sensor network node has typically several parts: a radio transceiver with an internal antenna or connection to an external antenna, a microcontroller, an electronic circuit for interfacing with the sensors and an energy source, usually a battery or an embedded form of energy harvesting. CHALLENGES 1) Resource constraints 2) Dynamic topologies and harsh environmental conditions 3) Quality-of-service (QoS) requirements 4) Security 5) Large-scale deployment and ad hoc architecture 6) Integration with Internet and other networks And More… e.g. 7) Data redundancy 8) Packet errors and variable-link capacity DESIGN GOALS 1) Low-cost and small sensor nodes 2) Scalable architectures and efficient protocols 3) Data fusion and localized processing 4) Resource-efficient design 5) Self-configuration and self-organization 6) Time synchronization 7) Fault tolerance and reliability 8) Secure design And More… e.g. 9) Adaptive network operation 10) Application-specific design CHALLENGES VERSUS DESIGN GOALS Challenges Versus Design Goals in IWSNs DESIGN PRINCIPLES AND TECHNICAL APPROACHES The design principles and technical approaches in IWSNs are broadly classified into three categories: 1) Hardware development; 2) Software development; and 3) System architecture and protocol design HARDWAR DEVELOPMENT 1) Low-Power and Low-Cost Sensor-Node Development 1) Sensor Four basic components 2) Processor; of industrial sensor node 3) Transceiver; 4) Power source 2) Radio Technologies 3) Energy-Harvesting Techniques SOFTWARE DEVELOPMENT 1) Application Programming Interface (API) In IWSNs, the application software should be accessible through a simple application programming interface (API) customized for both standards-based and customer- specific requirements 2) Operating System and Middleware Design very critical to balance the tradeoff between energy and QoS requirements. TinyOS is one of the earliest operating systems Introduction to IWSN standards: Zigbee and WirelessHart Both Zigbee and WirelessHart share IEEE 802.15.4 as the basis of their Physical and Data Link layer in the Open System Interconnection model (OSI model) The 802.15.4 standard defines a communication layer at level 2 in the OSI model and uses 27 frequency Channels: 868.0 - 868.6MHz -> 1 channel 902.0-928.0MHz 2.40-2.48GHz (Europe) -> 10 channels (USA) -> 16 channels (Worldwide) The reason that IEEE 804.15.4 has a good performance against noise is that the information is modulated using Direct Sequence Spread Spectrum (DSSS) technique before being sent to the physical layer in this standard. Encryption is one of the basic services provided by Zigbee (application and network keys implement extra 128b AES encryption). This is the reason that Zigbee shows a better performance in secure data transmissions. On the other hand, the WirelessHart standard shows a better performance in real-time data transmission in industrial platforms compared to Zigbee. Moving up to the network layer, WirelessHART represents a true mesh network, with each node capable of serving as a router. Wireless Sensors Using Zigbee and WirelessHart Standards Electrochem FS1, Wireless Flow Sensor Using Zigbee Standard Patent-Pending PS1, Wireless Pressure Sensor Using Zigbee Standard The SITRANS P280 wireless pressure sensor • Supports the WirelessHART standard (HART V 7.1) • Very high security level for wireless data transmission • Optimum display and readability using graphical display(104 x 80 pixels) with backlight • Stand-by (deep sleep phase) can be activated and deactivated with push of a button • Battery power supply, Battery service live up to 5 years • Optimized power consumption through new design, and increase in battery service life • Can be used for absolute and gauge pressure measurements Emerson Process Management has developed a Smart Wireless Network using WirelessHart products which is automating temperature and flow monitoring to increase production on the company’s Gullfaks offshore platforms in the northern part of the Norwegian North Sea. Needing a monitoring approach able to be installed without interrupting flow, operators are using wireless devices to transmit real time data that monitors temperature and flow. The developed WSN is allowing quick reaction to any loss of well pressure and maximizing throughput from the well. A loss in wellhead pressure was occasionally causing in flow losses from the producing wells at Gullfaks A, B and C platforms which belong to StatoilHydro, the leading oil and gas operator on the Norwegian continental shelf. Since there were no flow-metering devices installed within the well pipes, it was very difficult to detect the loss of flow. Installing such devices for this application was not practical as this would require a complete shutdown of production, which would be far too expensive in terms of lost throughput. Needing to automate the monitoring so as to provide real-time data, while also reducing personnel presence in hazardous areas, StatoilHydro initially implemented a pilot installation on the Gullfaks A, B & C platforms. Wireless transmitters were installed to indirectly indicate temperature and flow on lines at each of forty wells. The temperature range on the flowline surfaces of interest at Gullfaks A is about 50-70°C during normal operation. A lower threshold limit is usually set in the Process Control and Data Acquisition (PCDA) system. When temperature drops to this value, an alarm is triggered to indicate a pressure loss. The threshold value varies slightly from well to well, depending on the well characteristics. The table on next slide shows examples of operating temperatures and lower threshold values (alarm limits) for four wells at Gullfaks A. Well operating temperatures and alarm limits Well Operating temp., °C Alarm limit, °C 1 68 63 2 63 55 3 55 52 4 59 55 Lab Tests Deployment and installation of equipment at an offshore platform is a costly and time-consuming procedure. To ensure that the chosen system compiled with the Gullfaks requirements, the system was tested in the laboratory facilities at StatoilHydro’s research center in Trondheim, Norway, using real-size replicas of equipment used in StatoilHydro’s installations. The test network comprised five wireless transmitters and one gateway. It was deployed and monitored for about 40 hr. The wireless transmitters were positioned to provide a challenge to the capabilities of the network, especially regarding wireless communication in areas with lots of metal structures and no direct line-of-sight conditions. Next slide shows the lab network topology. The lab network topology at the end of the test period The network performance (latency, stability and reliability) is shown in figure below. The network has an initialization phase of about 1-2 hr, during which the mesh network topology is created and the optimal routes are chosen based on a tradeoff between high stability/reliability and low latency. After this initial phase, the network remained stable for the duration of the test period. The latency varied from about 1.5 sec. to 2 sec., the stability ranged 96-100%, and the reliability remained at 100% for the entire test period. Integration with Process Control and Data Acquisition (PCDA) system Transmission of digital measurement data from the gateway to the PCDA system is based on the Modbus serial protocol. A wired communication link from the gateway to a Modbus interface in the PCDA controller node was installed which is shown here. Conclusion In contrast with the once-a-shift manual recordings, Emerson’s wireless devices now transmit readings every 30 seconds back to the Smart Wireless Gateway. The gateway is hardwired straight into the existing control system providing operators with the real time information they need to react quickly to any change in flow. The combination of quicker and more reliable detection of lost flow enabled by the WSN, and the gained possibility of prompt action to reestablish flow, has an estimated annual net present value of $40 million for the Gullfaks A offshore facility. The network performance of the WSN solution has fulfilled the application requirements, providing practically 100% reliability with the acceptable latency. This shows that WSNs are fully capable of robust and reliable communication in the harsh environment found on offshore platforms. Thanks for your patience and attention…