Conduit and Convoluted Tubing

advertisement

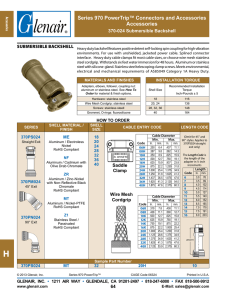

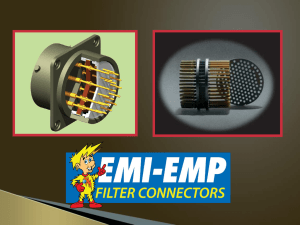

Glenair Backshells: Outstanding Performance and Availability Why Connectors Need Backshells Common Connector Problems and Solutions Problem Solution Environmental Damage Cable Sealing Backshells and Protective Covers Electromagnetic Interference EMI/RFI Shield (Screen) Termination Backshells Mechanical Damage to Conductors Strain-Relief Backshells Mechanical Damage to Pins and Threads Protective Covers and Boots Connector-to-Cable Routing Multiple Angle and Profile Backshells Cable and Conduit Integration Transition Fittings and Adapters Glenair Backshell Product Lines Backshells and Accessories for Every Application Glenair Circular Connector Backshells and Accessories Mil-Spec Backshells and Connector Accessories Rectangular Connector Backshells Composite Thermoplastic Connector Accessories Backshell Assembly Tools, Banding Tools and Accessories Specifying Mil-Spec Backshells AS85049, M24758, M28840, M38999 and Other Military Specifications NO GAPS: Glenair has every QPL with most slash sheets in stock Use Wall Chart for Scratch Selection Use Part Number Index to Match Part Number and Catalog Page Use Military Part Number Reference Guide to Cross Mil-Spec Numbers to Glenair Commercial Series Parts Internet: QwikCreate Part Number Builder and NSN Cross Reference Glenair Circular Connector Backshell Part Number Systems Ref: Big Red Book of Backshells Glenair Product Code/Product Series System 310 – Shrink Boot Adapter 360 - Non-Environmental Strain-Relief Backshell 370 - Environmental Strain Relief Backshell 380 - Non-Environmental EMI/RFI Backshells 390 - Environmental EMI/RFI Backshells 440 - Banding and Crimp Ring Adapters 450 - Qwik-Ty Strain-Reliefs 620 – Strain-Reliefs 660 – Protective Covers Cable Sealing Backshell Designs Three Basic Options Submersible: Cable sealing grommet, follower and backshell counterbore provides immersion protection to 2 meters. Water-Tight: Integrated cable sealing grommet provides immersion protection to one meter. Splash-Proof: light duty design provides moisture and dust resistance only EMI/RFI Backshell Designs Glenair Supports Every Industry-Standard Design Single and Multiple Conical Rings Crimp Rings Banding Terminations Castellated or Splined Rings Lampbase Thread Rings Radial Compression Springs Integrated Shield Socks Magnaforming Tinel Lock-Rings Band-it Shield Termination System Fast and reliable RFI/EMI/EMP shield termination No welding, soldering, crimping or magnaforming required - fully field repairable shield terminations Fast, highly reliable terminations virtually eliminate EMI leakage and pass severe shock, vibration and thermal tests “One size fits all” tool and band design provides unmatched flexibility In stock and ready for same-day shipment Cable Strain-Relief Designs Matching the Technology to the Application Straight and Angled Designs Light, Medium and HeavyDuty Saddle Bars Qwik-Tys QwikClamps Others Backshell Angle and Profile Critical Step in Cable Routing Design Standard Profile Low Profile Full Radius Profile Low Profile Split Shell Ultra Low Profile Split Shell Straight, 45 and 90 Degree Backshell-to-Connector Coupling Five Basic Designs Direct Coupling Rotatable Coupling Self-Locking Rotatable Coupling Positive-Lock (NESTOR) Non-Detent Coupling Composite “G-Load” Coupling Rectangular Backshells Complete Backshell Support for All Rectangular Connector Families MIL-C-24308 MIL-C-81659 Configuration MIL-C-83733 ARINC Series 600 MIL-DTL-83513 Cannon Series 400 MIL-C-83527/A All the Rest Composite Thermoplastic Designs For advanced weight savings to corrosion protection Weight savings: 40% over aluminum Corrosion protection: unlimited Inherent shock and vibration dampening Reduced magnetic and acoustic signatures (stealth) Cadmium free Flame resistant, chemical resistant and high-temperature tolerant Dimensionally stable Accepts plating for EMI/RFI protection Part Number Development The bread and butter of accessory specification Product Series Connector Designator Angle and Profile Basic Part Number Finish Symbol Shell Size Cable Diameter Strain Relief Style Length of Part Other: Drain holes, attachment lengths, special modifications QwikCreate Internet-Based Automated Part Number Development Build or analyze part numbers via a simple menu interface Generate printable document with all relevant dimensional data Link to catalog page for additional information Automatically select for Style 2 cable entry Link to on-line order entry Backshell Assembly and Connector Holding Tools Full 360o gripping surface of backshell coupling nuts and connector plugs and receptacles For production and field maintenance Manual and pneumatic hand tools, strap wrenches and torque wrenches M83507/15-01, TG70 and TG80 circular connector tools Complete kits and/or individual tools and parts In stock and ready for same-day shipment Glenair’s Position in the Marketplace Full-Service, High-Availability Interconnect Solutions Full Spectrum Product Lines —No Gaps Fast, Personal Response to RFQ’s Vertically Integrated Factory No Third World Subs Same Day Availability for 45,000+ Commercial and Mil-Spec Accessories Worldwide Service and Support