IPT and IPT SE Bayonet-Lock Connectors

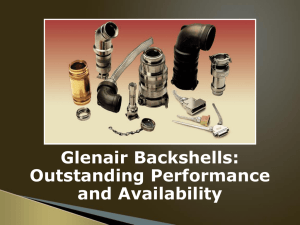

advertisement