Day 1 Spring 2011 - Rose

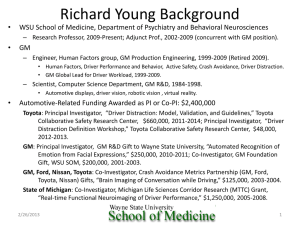

advertisement

Chapter 1: Introduction Product Design and Development Fourth Edition by Karl T. Ulrich and Steven D. Eppinger Why are we here? • How does this course help me be a better engineer? • How does this course fit into the curriculum? We want you to be able to solve problems To solve problems, you need • Skills • Knowledge Some problems are technical and some are not. Let’s Look at Two Problems • Suzlon Wind Turbine Blades • Toyota Accelerator Issues. Suzlon Wind Turbine • In 2008, Suzlon held more than 50 percent of the Indian market for wind and 12.3 percent of the global market. http://www.topnews.in/companies/suzlon-energy Problem • On October 24, 2008 a Suzlon wind turbine in Wyanet Illinois and one of its 140 foot long blades break off. http://gigaom.com/cleantech/holy-breaking-wind-turbines/ • Root Cause Analysis and Identification • Suzlon engaged Navigant Consulting, to conduct an extensive Root Cause Analysis (RCA) • While designed and tested to industry standard certification guidelines, the blade had a weakness in the transition area - about 6 meters (20 feet) from the root of the blade. The blades measure 43 meters (142 feet) long and weigh 7 tonnes (15,650 pounds). • At the completion of the program, only 179 blades of the total fleet of 1,251 blades developed cracks. However, Suzlon upgraded the entire fleet in support of its customers. http://www.prnewswire.com/news-releases/suzlon-completes-blade-retrofitprogram-64007317.html This looks like a technical problem. How do you (as a designer) prevent this from happening? Toyota Accelerator Problem http://www.toyota.com/recall/videos/pedalassembly.html Recalls • Nov 02, 2009 – US: 3.8 million Toyota and Lexus vehicles again recalled due to floor mat problem, this time for all driver's side mats.[5] • Nov 26, 2009 – US: floor mat recall amended to include brake override[32] and increased to 4.2 million vehicles.[citation needed] • Jan 21, 2010 – US: 2.3 million Toyota vehicles recalled due to faulty accelerator pedals[6] (of those, 2.1 million already involved in floor mat recall).[3] • Jan 27, 2010 – US: 1.1 million Toyotas added to amended floor mat recall.[33] • Jan 29, 2010 – Europe, China: 1.8 million Toyotas added to faulty accelerator pedal recall.[7] Toyota Will Pay Additional $32.425 Million as Result of 2 DOT Investigations Dec. 20: Toyota has agreed to pay an additional $32.425 million in civil penalties as the result of two separate investigations into the automaker's handling of auto recalls. Toyota will pay the maximum fines allowable under the law - $16.375 million in one case and $16.050 million in the other - in response to the Department's assertion that it failed to comply with the requirements of the National Traffic and Motor Vehicle Safety Act for reporting safety defects to NHTSA. http://www.nhtsa.gov/Vehicle+Safety/Additional+Information+on+Toyota+Re calls+and+Investigations Wheels: NASA: "Toyota problem not rocket science" by John Shook, Lean Enterprise Institute http://www.designfax.net/enews/20110301/ feature-4.asp NHTSA-NASA Study of Unintended Acceleration in Toyota Vehicles http://www.nhtsa.gov/UA What was the Toyota Problem? • Mostly NOT technical. (Electronics cleared by NASA) • It was a perception problem. • The problem resulted when the opposition took control of the story. • How do engineers deal with nontechnical problems? http://www.designnews.com/article/455235Friction_Fundamentals_and_Accelerating_Cars.php The accelerator pedal assemblies in the vehicles (Tundras) contained a friction lever made of the polyamide (nylon) 4/6 material. Toyota's investigation found that the material was susceptible to humidity, which could cause the friction lever to absorb moisture and swell. It is well known that nylon is a hygroscopic (waterabsorbing) polymer. http://www.designnews.com/article/448825Poor_Plastic_Selection_Caused_Gas_Pedal_Failures.php?nid=2334&rid=2501252 How do we design to avoid technical and nontechnical problems? • How do we select design goals and constraints for an accelerator pedal assembly? (e.g. Grab three other engineers and go to a conference room for an hour.) • How do we explore possible solutions? • How do we select a “best” solution? Course has Three Significant Components • Design Process and Methodology. • Using Statistics to developing and apply Math Models for design (DOE and Robust Design). • Economic Decision Making Goals of Book and Course • Examine structured approaches to product design and development (e.g. functional decomposition, set-based design, …) • Develop the knowledge and tools to be able to work successfully on cross functional teams (e.g. identify customer needs, intellectual property, economic decision making, …) Bias of the Book • Assumes a For-Profit enterprise • Considers primarily Discrete Goods (printers, and power drills rather than plastic film) • Considers primarily Physical Products rather than engineering services or software. Bias of the Teacher SMIU Rules for Good Design • Does not hurt anyone • Makes money • Works OK Excellent Design • Enhances lives • Makes tons of money • Delights the user Role of Structured Methods • Creativity vs. Recipe in design • Creativity vs. Recipe in product development process Pretty Good Pictures of the Disassembled gas pedal assembly: http://www.thetruthaboutcars.com/exclusive-ttac-takesapart-both-toyota-gas-pedals/ Reasonable overview of the Problem with pretty good pictures. http://www.thetruthaboutcars.com/why-toyota-must-replace-flawed-cts-gas-pedal-with-superiordenso-pedal/ Interface of interest. Comment on Design News Article about the Toyota Accelerator Issue: I don't believe that Engineering at Toyota was not aware of a problem or concerns in a Safety Critical system like a drive by wire accelerator. Proper Failure Mode Analysis was not done or the risk evaluated too small. http://www.designnews.com/article/talkback/448825Poor_Plastic_Selection_Caused_Gas_Pedal_Failures.php#142509