Performance Measurement

advertisement

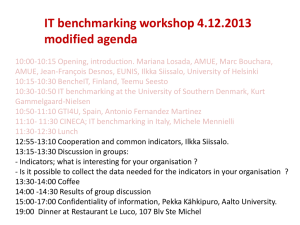

Performance stream status EAQG performance benchmark York General Assembly Alain Bonnard Christian Buck October 22nd 2010 4/13/2015 Company Confidential Performance stream supports IAQG 5 years vision development • Product and Services Quality and Delivery will have improved 20% per year throughout the product lifecycle • Robust processes achieved throughout the Supply Chain (SCMH supplier maturity assesment level 3 or better) • IAQG Quality management system certification program robust, recognised and valued • 90% of the industry supply chain certified to IAQG Quality Management System Standards Aerospace and Defense Performance Index • A process consolidating, reporting and publishing the measurement of the whole aerospace and defense supply chain progresses toward the 20% improvement goal • Based on observed and sampled On Time Deliveries – On Quality Deliveries • Measurements based on standard “metrics definitions” • A process allowing each supplier to find its position within the index and to set improvement objectives by itself or in the frame of a customer-supplier relationship Performance Index Process Loop Suppliers OTD OQD IAQG members observe their suppliers performances IAQG members select a representative sample of suppliers data Performance Agency consolidates data (members anonymous) Suppliers & customers set improvement goals Each supplier is able to find its position in the index IAQG members provide data to Performance Agency (suppliers anonymous) IAQG Council review to 20% improvement goal IAQG publishes data (e.g. next slide) 4 Performance Index Possible Publication Item Escape Rates Distribution Sample of 138 suppliers Deterioration 2008 2007: 4000 ppm 2008: 3500 ppm 2007 Improvement 2007 2007: 443 ppm 2008: 392 ppm 2008 2007: 10 ppm 2008: 5 ppm On Quality Performances 2007/2008 Evolution 5 EAQG Supply Chain Benchmarking IAQG General Assembly York, UK, October 22nd, 2010 Alain BONNARD EAQG Operations Manager Benchmarking Benchmarking Project EAQG Benchmarking Project EAQG Initiative launched within the IAQG European Sector • Project concept defined in 2009 • Decision to proceed taken in September 2009 • Considered as a Pilot Case • Participation from EAQG Company Members based on a voluntary basis • Data collection started in January 2010 Goal: Get EAQG Supply Chain 2010 Performance level 7 Benchmarking Principles 1. Benchmarking Principles • 2 Performance Metrics » Conformity (Item Escape rate in PPM) » Punctuality (On time Delivery in %) • Suppliers Performance only » Average of EAQG Suppliers Performance for each Business Unit (if any, optional*) identified by EAQG participating companies (2 data / Per Business Unit) » Average of EAQG Suppliers Performance for each Technological Segment (Optional*) of each Business Unit (2 data / Per Business Unit / Per Technological Segments) (Optional*) : To be decided by EAQG participating Companies 8 Benchmarking Principles 1. Benchmarking Principles (Cont’d) • General results (All Technological Segments together = Average of Suppliers Performance for each Business Unit identified by EAQG Companies) – Graph / metric » Conformity (Item Escape rate in PPM) » Punctuality (On time Delivery in %) – Graph / metric per Technological Segment (for EAQG participating companies willing to have Technological segments) Each EAQG Member is receiving the same General results 9 Benchmarking Principles 1. Benchmarking Principles (Cont’d) • Customized results (per company) – Graphs / Metric (Conformity & Punctuality) with identification of your company Business Units (Optional*) – Graphs / Metric per Technological Segment (Optional*) with identification of your company Business Unit (Optional*) : To be decided by EAQG participating Companies Each EAQG Member is receiving the Graphs with its Business Units Company positions on the graph 10 Metrics Definition 2. Metrics Definition » Conformity: • Escape – Non Conformity level after delivery to the customer Item Escape Rate expressed in PPM (Definition in § 7.1.1 IER) » Punctuality: • On Time Delivery of items to the customer Delivered items expressed in % Double click to open the document (Definition in § 8.1 OTD) Period of Measurement: 6 months rolling average or in exceptional case 12 months based on volume of parts According to Metrics definition made by EAQG Working Group 11 Industry Segments 3. Technological Segments Benchmarking per Technological Segment • Option to have the benchmarking results per Technological Segment • 5 defined Technological Segments made by the dedicated Working Group after collection of identified segments made by each EAQG participating Member (See 5 Segments next slide) 12 Industry Segments 3. Technological Segments Definition EAQG segment id. EAQG segments keywords TS1 Details parts or machined parts or metal machining or manufactured parts or finished parts TS2 Systems or equipments or avionics or others sub systems suppliers TS3 Raw material or forging or casting or non metallic material or plastics parts suppliers TS4 Hardware or technical products or fasteners or wiring TS5 Barrels, aerostructures, structures suppliers 13 EAQG Members 4. EAQG Company members Advanced Electronics Company AgustaWestland Airbus Airbus Military Alenia AVIO BAE Systems Cassidian Dassault Aviation EADS ASTRIUM Elbit Systems Eurocopter Fokker Aerospace GE Aviation Systems HEGAN (ITP) Hispano Suiza IAI Liebherr MBDA Meggitt Messier-Dowty MTU PFW RAFAEL Rolls-Royce SAAB SAFRAN SAGEM SNECMA SONACA SUKHOI THALES Turbomeca Volvo Aero. ZODIAC Aerospace 14 Participating EAQG Members 5. Participating EAQG Company members EAQG Benchmarking 2010 Number of EAQG Members participating Number of EAQG Members NOT participating Total EAQG Company Members Participation Rate 22 13 35 63 % Percentage of participation: • / of Total EAQG Companies: 63 % 15 Benchmarking Results Benchmarking All 55184 16 Benchmarking Results Benchmarking All 69 % 22 Benchmarking Results Benchmarking Comparison with Automotive industries All Aerospace & Defence Automotive 55184 393 28 Benchmarking Results Benchmarking Comparison with Automotive industries All Aerospace & Defence Automotive 69 % 95 % 29 Benchmarking Results 6. Benchmarking Results Benchmarking Data Type Ave-rage TS1 TS2 TS3 TS4 TS5 Conformity (ppm) 55.184 15.979 130.638 55.081 46.663 5.209 Punctuality (%) 69 77 68 80 79 67 Comparison Conformity (ppm) Punctuality (%) Aerospace & Defence Automotive 55.184 393 69 95 30 Next Steps 7. Next Steps Extend Performance Metrics initiative at IAQG level (IAQG Strategy Improvement stream – Performance) To be implemented early 2011 at International level 31 Performance Index Development • Whole Aerospace and Defense Supply Chain is estimated to : – 14000 sites certified to 9100, 9110 or 9100 sites – 8000 sites planning certified (rough order of magnitude) – Several thousands of other suppliers • A representative sample of this supply chain is around 500 suppliers, • Global development plan leads to first index publication in spring next year • Any suppliers willing to join are welcome 32 Questions? 33