Benchmarking in Logistics and Supply Chain Management

advertisement

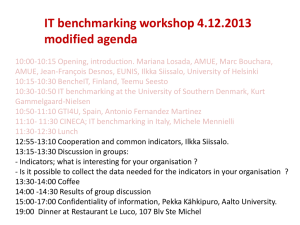

Benchmarking in Logistics and Supply Chain Management Compiled by Rulzion Rattray 1 Benchmarking. • What is benchmarking? – Ongoing process of measuring products, services, practices & processes against the best that can be identified in order to: • • • • • • • Learn about & improve best practice. Achieve realistic targets. Integrate improvements into your strategy. Use best practice as inspiration for innovation. Be externally focused. Be purposeful about improvement. Measure improvement. 2 Benchmarking • A control process. – Involving employees in the process of evaluation and change. – Philosophy one of self control rather than imposed control, where the person most closely associated with the task is involved in the cross measurement and assessment of practice. – Places personnel in a position where their unquestioned beliefs (paradigm) may be challenged , creating opportunities for innovation and learning. 3 Benchmarking the Supply Chain • What to Benchmark? – Supply Chain Council suggests: • SCOR (Supply Chain operations reference) Christopher, M. 1998 pp 106): • Plan, Source, Make & Deliver. SCOR is designed to provide a common framework to facilitate cross organisational benchmarking. • Who to Benchmark with? – Competitors – Significant opportunities for firms in non competing industries 4 Benchmarking Logistics Processes •One method to measure and compare the output. A form of reactive control. •Alternative to concentrate on the processes which requires a number of steps: 1 Understand the process. Use those most closely involved and develop flowcharts 2 Identify critical points 5 Mapping Supply Chain Processes • Producing a flow chart the first step and highlighting “value adding” time and “nonvalue adding time” (Christopher, M. 1998 pp 110). – Value Adding Time: • Time that results in increased value for the customer – Non Value Adding Time: • Elimination of this time or activity would not reduce the perceived value of the ultimate consumer. 6 Cost and Value added: Value Added Time place & form perception Transport Finished product Regional Stock Customer order Production Raw material Time! Cost Added Production, Storage & transport costs & the time value of money Adapted from Christopher, M., (1998), “Logistics and Supply Chain Management. Strategies for Reducing Cost and Improving Service”, Financial Times Pitman Publishing, London. pp 111. 7 Suppliers and Distributors • Involve inbound and outbound elements fo the value system. Their cost will add to the ultimate cost! • Establish and Encourage: – – – – – Commitment to continuous improvement. Acceptance of innovation and change. Use of regular and formal and benchmarking. Employee concern for the ultimate consumer. Leadership involvement 8 Setting Benchmarking Priorities Strategic Importance Processes that are competitively critical Relative impact on business. •High total cost •High revenue •High human input Organisational Readiness Benchmarking priorities Make V Buy Economics Processes with high impact on value and hard to outsource Processes carried out by “ready to improve personnel”. Adapted from Walleck et al, (1991) “Benchmarking World Class Performance”, The McKinsey Quarterly, Cited in Christopher, M., (1998), “Logistics and Supply Chain Management. Strategies for Reducing Cost and Improving Service”, Financial Times Pitman 9 Publishing, London. Pp118. Key Performance Indicators • Highlight issues regardless of measurability that have high impact on the organisational success. – – – – Articulate the strategic objectives to personnel. Understand measurable outcomes of success. Communicate importance of key processes. Highlight and focus attention on key performance indicators. • Better faster Cheaper! 10 Conclusions. • Benchmarking vital tool in maintaining world class status. • Massive potential for developing learning and innovation. • Supply chain mapping useful in ensuring that the whole system is kept in view. 11 References • Christopher, M., (1995), “Logistics the Strategic Issues”, Chapman Hall, London. • Christopher, M., (1998), “Logistics and Supply Chain Management. Strategies for Reducing Cost and Improving Service”, Financial Times Pitman Publishing, London. • Kaplan, R.S. & Norton, P., (1992), “The Balanced Score Card - Measures That Drive Performance”, Harvard Business Review No 92105, January February. • Walleck A.S., et al, (1991), “Benchmarking World Class Performance”, The McKinsey Quarterly, No. 1. 12