Orbital Presentation

advertisement

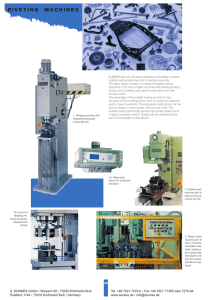

EU EN R2.D - MAY 2013 Company Data ESTABLISHED: 1985 HEAD OFFICE: Mumbai TURNOVER (FY 2012): 6 Million USD EMPLOYEES: 100 CERTIFICATIONS: ISO 9001 COMPETENCES: Mechanics Electronics Software Robotics Vision Special purpose machines 1985 1985 Company founding In Mumbai 1998 First Export (U.S.A.) 1990 1995 2000 1994 S.O.P. Light Curtains 2004 S.O.P. Assembly Automation 2005 2010 2012 EU-based cooperation establishment 2015 2000 S.O.P. Cam Index Table 2008 ISO9001 QMS Certification Facts & Figures 1988 Additional works in Nasik set-up Head Quarters NASHIK MUMBAI (NEW) Mumbai Works Mumbai (400 sqm) Nashik (4650 sqm) Mumbai (2800 sqm - opens 2Q 2013) Offices Ludhian a Delhi (2 sales, 2 service, 1 controls) Pune (2 sales, 1 service) Bangaluru (1 sales, 1 service) Chennai (1 sales, 1 service, 1 controls) Delhi Nashik Nagpur Jamshedp ur Kolkata Aurangab ad Mumbai Pune Bangalu ru Representatives / Dealers Hyderaba d Ahmedabad Košice SLOVAKIA Chennai Kochi Turin ITALY Indore Hyderabad Jamshedpur Kolkata GLOBAL SERVICE POINTS MEXICO china Saltillo, Coahuila Hangzhou canada poland london, on Bielsko-biala Sacel Srl (EU Joint Venture) Nagpur Turin (Italy) Aurangabad 2 Plants Locations Ahmedaba d DIRECT (74) 8 12 4 7 18 10 (+12*) 5 3 3 4 (*) ADDITIONAL 12 PEOPLE IN SEPARATE GROUP’S COMPANY INDIRECT (24) DESIGN DEPT. QUALITY CONTROL DEPT. TOOL MACHINING SHOP FINAL ASSEMBLY AREA Human Resources PROJECT MANAGEMENT: MECHANICAL DESIGN: ELECTRIC / PNEUMATIC DESIGN: PC /SPS SOFTWARE: MECHANICAL ASSEMBLY: MACHINING: ELECTRICAL ASSEMBLY / WIRING: DOCUMENTATION: QUALITY ASSURANCE: CUSTOMER SERVICE & CARE: ORBITAL RIVETING HEADS / STATIONS HYDRO-PNEUMATIC / HYDRAULIC PRESSES CLINCHING HEADS / STATIONS SAFETY LIGHT CURTAINS SCREWING STATIONS GLOBOIDAL CAM INDEX DRIVES Product Portfolio STANDARD PRODUCTS (MANUFACTURED) INTERNATIONAL PARTNERS ASSEMBLY AND TESTING EQUIPMENTS METAL PUNCHING DIES METAL /PLASTIC DIRECT MATERIALS PRODUCTION HELIUM LEAK TESTING EQUIPMENT ROBOTIC CELLS SMART VISION APPLICATIONS Know-How ROBOTIC CELLS HANDLING SYSTEMS Market REFERENCE CUSTOMERS Assembly & Test Equipment CUSTOM EQUIPMENT FOR FACTORY AUTOMATION BENCHES AUTOMATIC MODULES ROBOTIC CELLS Product Portfolio ROTARY INDEXING TABLES COMPETENCIES ASSEMBLY ROBOTICS KAN-BAN / PALLETIZERS LASER MATERIAL PROCESSING ORBITAL RIVETING CLINCHING RESIN DISPENSING PLASTIC WELDING CONTROLLED SCREWING HYDRAULIC CALIBRATION & TEST LEAK TEST (AIR & HELIUM) CAMERA SYSTEMS INDUSTRIAL CUSTOMIZED SW PRODUCT CO-DESIGN LEAN MANUFACTURING Product Portfolio ELECTRIC CALIBRATION AND TEST CUSTOMER: Aditya Auto Pvt. Ltd. - Ford (Bangalore) APPLICATION: Riveting & Greasing Machine for car latch Machine features Rotary Indexer Riveting machine Model 012 Metered quantity Greasing Component presence checking Arrangement for component assembly & Inspection PLC & Pneumatic Controls Reject component bin arrangement Table structure with anti -vibration pads. Application Examples Basic Operation: Riveting, Greasing, Assembly Inspection. CUSTOMER: Magneti Marelli Shock Absorber Pvt. Ltd. (Pune) APPLICATION: Piston Valve + Rod / Foot Valve Assembly Piston Valve + Rod Assembly Foot Valve Assembly Rotary Indexer Auto sequence for loading of component. Bowl feeder for positioning component 08 variants of the Valve Coining with Force/Stroke measurement and monitoring Application Examples Rotary Indexer Auto sequence for loading of component. Bowl feeder for positioning component 08 variants of the Piston rod Loctite Dispensing A-Class Screwing CUSTOMER: Epcos India Ltd. (Nashik) APPLICATION: Semiautomatic Capacitor Can Assembly Machine Machine features Auto Feeding & Loading of the Can Component presence checking Element Pressing Grooving and pressing Auto Unloading by Pick & Place Jacking arrangement to accommodate length variety. Application Examples Basic Operation: Grooving on Aluminium can 0.5mm thick and diameter 25mm to 70mm. Pressing the same groove to form a thin step inside the Aluminium can. CUSTOMER: Asmo (Japan) APPLICATION: Wiper Motor Rotor Assembly Commutator Press fitting Pneumatic press Auto Sliding mechanism Poka Yoke PLC & HMI Application Examples Shaft Press fitting Hydraulic 10T press Manual Indexing mechanism Poka Yoke PLC & HMI CUSTOMER: LYTE Industries LTD (Swansea, UK) APPLICATION: Ladder Riveting SPM Six point riveting at a time Transfer mechanism. Auto Lubrication before riveting to improve finish. 17 variants of the Ladder Roller Conveyors for inputs and Output material handling Application Examples (2013 NEW EQUIPMENT WILL INCLUDE ROBOTIZED MIG-WELDING CELL) CUSTOMER: Nuclear Fuel Complex (Hyderabad) APPLICATION: Automated Density Measuring System 3- GRIPPERS PICK AND PLACE IN-WATER WEIGHTING IN-AIR WEIGHTING OUTPUT TRAY Application Examples INPUT TRAY CUSTOMER: Cogeme Precision Parts India Pvt. Ltd. (Pune) APPLICATION: Variable Geometry Turbocharger Assembly HYDROPNEUM. PRESS (4 TONs) 005 ORBITAL RIVETING HEAD X-Y AXIS CNC TABLE NOZZLE PIPE RIVETING FIXTURE NOZZLE RING RIVETING FIXTURE PIN & ROLLER PIN PRESSING FIXTURE PROCESS CONTROL LOAD CELL FIXTURE LOCKING UNIT PUNCH HOLDER ASSLY FIXTURE DE-CLAMPING UNIT Application Examples PIN & ROLLER PIN SENSING UNIT Application Examples CUSTOMER: Savera Furniture – IKEA (Aurangabad) APPLICATION: Chair Frame Welding with ABB 6 axis Robot European Presence SACEL SRL 1975 HEAD OFFICE: San Giorgio Canavese (TO) - ITALY TURNOVER: 18,5 Million Euro EMPLOYEES: 140 PRODUCTION (ITALY) TOOL-MAKER (ITALY) PRODUCTION (SLOVAKIA) METAL STAMPED PARTS OVERMOLDED , ASSEMBLED, WELDED PARTS PLASTIC INJECTED PARTS FACTORY AUTOMATION, DIES DESIGN AND MANUFACTURING MARKETS QUALITY CERTIFICATIONS ISO 9001 ISO/TS 16949 ISO 14001 Sacel - EU Partner ESTABLISHED: SACEL SRL OZEGNA (TO) 1800SQM – 30 EMPLOYEES HEAD-QUARTERS, SALES, ACCOUNTING, R&D , TOOL SHOP, AUTOMATION SAN GIORGIO (TO) 4500SQM – 60 EMPLOYEES Košice 3000SQM – 35 EMPLOYEES METAL STAMPING , PLASTIC INJECTION , OVER-MOLDING, ASSEMBLY, LOGISTIC, QUALITY, TOOL-MAINTEINANCE, INDUSTRIALIZATION Sacel - EU Partner METAL STAMPING , PLASTIC INJECTION , LASER WELDING, ASSEMBLY, LOGISTIC, QUALITY, MFG. ENG. SACEL SRL SINCE 2005 SACEL STARTED TO PRODUCE ASSEMBLY & TEST EQUIPMENT FOR ITS INTERNAL USE. ALONG LAST YEARS HAS BEEN DEVELOPING SEVERAL LINES (WITH SINGLE MARKET VALUE UP TO 500.000€) . Brushless-fan Baseplate (Automotive) Pacemaker (Medical) Lamp Connector (Automotive) Advantages: Short set-up time Use std. press for progressive dies Totally integrated in the tool AUT.E.L. (Automation End of Line) Operations attended: 1) Picking parts from high-speed process (i.e. stamping press) 2) Moving the parts to one or more checking stations (camera or other test) 3) Moving the parts to the final packing Productivity: 360-1800 pcs/hr. Project financed by MANUNET (EC Research project) Sacel - EU Partner ROTO-TRANSFER (Automation on Tools) FURTHERMORE, TWO STANDARD SYSTEMS ARE IN A DEVELOPMENT STAGE: PARTNERSHIP BENEFITS AND ROLES • BENEFITS • ROLES • • TO EXPAND ITS BUSINESS VOLUME IN AUTOMATION BUSINESS WITHIN EUROPEAN MARKET. TO GROW UP ITS POSITION OF AUTOMATION QUALIFIED SUPPLIER IN INDIAN MARKET, THANKS TO TECHNOLOGICAL IMPROVEMENT OBTAINED WORKING WITHIN EUROPEAN CUSTOMERS AND ITALIAN QUALIFIED TEAM. EQUIPMENT DESIGN, CONSTRUCTION AND SET-UP. SUPPORT IN EUROPE (IF REQUIRED). SACEL • • TO EXPAND ITS BUSINESS VOLUME BY APPROACHING AUTOMATION BUSINESS TO OTHER COMPANIES. TO CREATE NEW LINKS AND BUSINESS POTENTIAL OPPORTUNITIES WITH CUSTOMERS APPROACHED THROUGH THE NEW VENTURE FOR ITS TRADITIONAL BUSINESS UNIT. • SALES AND PROJECT MANAGEMENT. • EQUIPMENT COMPLETION (IF REQUIRED). • DELIVERY, COMMISSIONING, FINAL ACCEPTANCE, AFTER-SALES IN EUROPE. Sacel - EU Partner ORBITAL SYSTEMS ORBITAL SYSTEMS (BOMBAY) PVT. LTD. Headquarters : F-129, 109, Ansa Ind. Est. Saki Vihar Road, Mumbai - 400072 INDIA Nashik Works: F-19, Street No 18, MIDC, Satpur Nasik – 422007 INDIA Tel : +91-22-28473312 Fax : +91-22-28476675 Tel : +91-0253-6695800 Fax : +91-0253-6695858 www.orbitalsystems.net sales@orbitalsystems.net D&B D-U-N-S® N. 91-583-4683 SACEL S.R.L. Headquarters: Località Risera 10080 Ozegna(TO) ITALY San Giorgio C.se Works: Str. del Paschetto S/N 10090 San Giorgio C.se (TO) ITALY SacelEst s.r.o. Juzna Trieda 125 04001 Košice SLOVAKIA Tel : +39-0124-424077 Fax : +39-0124-27794 Tel : +39-0124-452991 Fax : +39-0124-4529920 Tel : +421-557995542 Fax : +421-918629124 www.sacelgroup.com customer-service@sacel.it D&B D-U-N-S® N. 33-886-1797 Contacts