riveting machines

advertisement

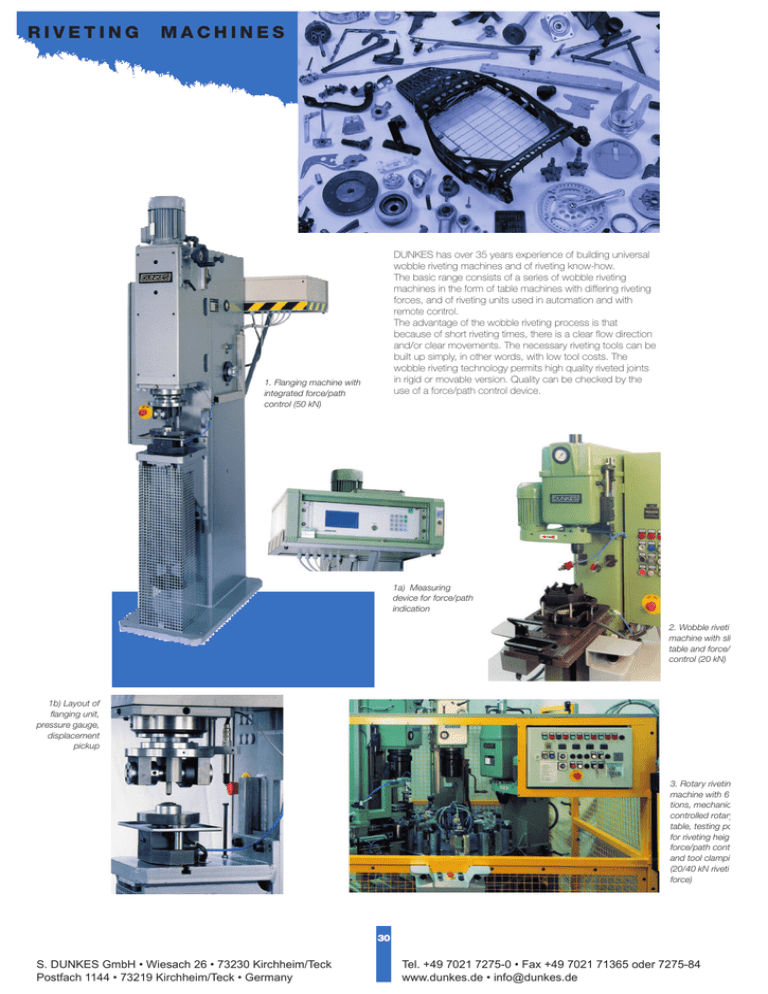

RIVETING MACHINES DUNKES has over 35 years experience of building universal wobble riveting machines and of riveting know-how. The basic range consists of a series of wobble riveting machines in the form of table machines with differing riveting forces, and of riveting units used in automation and with remote control. The advantage of the wobble riveting process is that because of short riveting times, there is a clear flow direction and/or clear movements. The necessary riveting tools can be built up simply, in other words, with low tool costs. The wobble riveting technology permits high quality riveted joints in rigid or movable version. Quality can be checked by the use of a force/path control device. 1. Flanging machine with integrated force/path control (50 kN) 1a) Measuring device for force/path indication 2. Wobble riveti machine with sli table and force/ control (20 kN) 1b) Layout of flanging unit, pressure gauge, displacement pickup 3. Rotary rivetin machine with 6 tions, mechanic controlled rotary table, testing po for riveting heig force/path cont and tool clampi (20/40 kN riveti force) 30 S. DUNKES GmbH • Wiesach 26 • 73230 Kirchheim/Teck Postfach 1144 • 73219 Kirchheim/Teck • Germany Tel. +49 7021 7275-0 • Fax +49 7021 71365 oder 7275-84 www.dunkes.de • info@dunkes.de 4. Wobble riveting machine with sliding table, tool clamping, force/path control, NC control, PC and printer (20 kN) In the case of automatic processes the rivet height tolerance can be checked before riveting. This can be monitored either in the form of a bar chart or with a force/path diagram. The DUNKES CNC riveting machine is used when a large number of rivets at close centres are required. Loading and unloading is not dependent upon time. A NC control enables the required riveting forces, times and reproducible path switch off points to be programmed. The data are stored on disks. The advantage of this system compared with multi-spindle heads is that no expensive individual riveting tools are required. 6. Riveting machine with automatic rivet feed using sorting boiler, automatic tool transport device (40 kN pressing force each) . CNC wobble riveting machine with 3 axis, reciprocating table for loading and unloading (20 kN) 7. Wobble riveting machine as a seated work place (riveting force 20 kN each) 8. Automatic riveting machine with 12-fold clip feed for console 31 S. DUNKES GmbH • Wiesach 26 • 73230 Kirchheim/Teck Postfach 1144 • 73219 Kirchheim/Teck • Germany Tel. +49 7021 7275-0 • Fax +49 7021 71365 oder 7275-84 www.dunkes.de • info@dunkes.de RIVETING MACHINES 3a) Wobble riveting unit disassembled; the machine can thus be used as a pneumatic press 3. DUNKES open-fronted wobble riveting machine with adjustable table (20 kN) 1. DUNKES wobble riveting machine as standard range (5 kN - 40 kN) 2. DUNKES wobble riveting unit as standard range (5 kN - 40 kN) 4. Open-fronted wobble riveting machine with multispindle riveting head and tool changer (100 kN) 5. Horizontal riveting machine with hydraulic riveting units (100 kN each) 32 S. DUNKES GmbH • Wiesach 26 • 73230 Kirchheim/Teck Postfach 1144 • 73219 Kirchheim/Teck • Germany Tel. +49 7021 7275-0 • Fax +49 7021 71365 oder 7275-84 www.dunkes.de • info@dunkes.de Working Examples for Rivet Head Types The wobble riveting method allows a wide variety of types of rivet heads to be used, even in inaccessible positions. Under normal circumstances either a 5° /3° or a 2° inclination of the rivet axle is used. Compared with the purely press-riveting system, the riveting force used here is about 1/10th. This largely eliminates deformation of the rivet waist in the hole. The rivet axis is driven pneumatically, or, in the case of higher riveting forces, hydraulically. Optional extras such as sliding tables for loading and unloading, automatic rivet feed, quality check using force/path control, rotary table or transfer options can be supplied as required. a b c d e f g h k l 6. Hydraulic open-fronted wobble riveting machine (100 kN) j i 8. DUNKES preci wobble riveting machine with mu spindle riveting he (20 kN) 7. DUNKES precision wobble riveting machine with adjustable head (20 kN) 9. Detail, pressure riveting with automatic rivet feed 10. Pressure riveting with automatic rivet feed (10 kN) 33 S. DUNKES GmbH • Wiesach 26 • 73230 Kirchheim/Teck Postfach 1144 • 73219 Kirchheim/Teck • Germany Tel. +49 7021 7275-0 • Fax +49 7021 71365 oder 7275-84 www.dunkes.de • info@dunkes.de P N E U M AT I C P R E S S E S DUNKES has a comprehensive basic range of pneumatic presses for many different kinds of applications. The main point of difference is whether the ram start is activated using the 2-hand system, a joystick or a foot pedal. An advantage of DUNKES joystick control is that the ram is moved absolutely synchronously to the joystick. Optional extras include adjustable table and mechanical depth stop for reproducible reversing accuracy. In the case of straightening presses, the straightening equipment is designed for the operation requirements in accordance with ergonomic principles. These extras enable specific customer requirements to be met exactly. The range of pneumatic presses with constant and direct force is an economic extension to the hydraulic presses at the lower end of the force range. 1. Pneumatic table press with hydraulic dampening unit for the ram axis. 2-hand operation (40 KN) ❒ Pressing ❒ Stamping ❒ Calibrating 3. Pneumatic sensitively controlled straightening press with lightcolumn measurement indicator (20 kN) ❒ Punching ❒ Straightening ❒ Pressure riveting ❒ Bending ❒ Assembling 2. Pneumatic openfronted press with adjustable table, sensitive handlever control, can be switched to 2-hand operation ❒ Jointing ❒ Caulking ❒ Trimming ❒ Flanging S. DUNKES GmbH • Wiesach 26 • 73230 Kirchheim/Teck Postfach 1144 • 73219 Kirchheim/Teck • Germany 34 Tel. +49 7021 7275-0 • Fax +49 7021 71365 oder 7275-84 www.dunkes.de • info@dunkes.de