View Powerpoint Presentation

advertisement

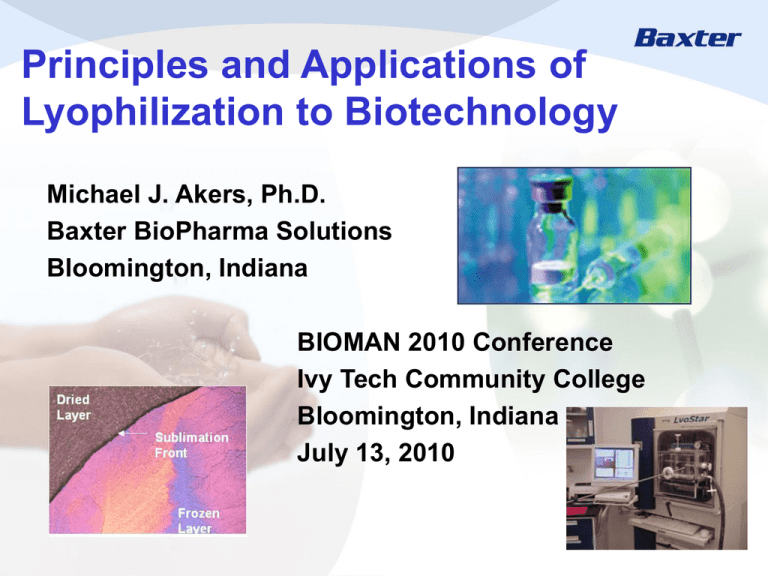

Principles and Applications of Lyophilization to Biotechnology Michael J. Akers, Ph.D. Baxter BioPharma Solutions Bloomington, Indiana BIOMAN 2010 Conference Ivy Tech Community College Bloomington, Indiana July 13, 2010 1 Baxter Confidential Organization of Presentation Baxter Briefs Biologics Market Lyophilization 2 Baxter Confidential Bloomington, Indiana Capabilities Overview Technologies Prefilled syringes Lyophilization Aseptic liquid vials Cartridges Diluent syringes Services Formulation development Process development Lyo cycle development Analytical development Regulatory support Labeling and Packaging Clinical to Commercial 3 Baxter Confidential Other Interesting Facts about Baxter BioPharma in Bloomington • Produce more prefilled syringes than any other manufacturer in North America • Small molecules, vaccines, proteins, diluents • Produce injectables marketed throughout the world • No history of FDA Warning Letters • 308 employees in 2001; 993 end of 2009 • Newest manufacturing building won ISPE facility of the year in 2006 Focus of Bloomington R&D Formulation Development of Small Volume Injectables Liquid Lyophilized Extensive experience with Proteins Monoclonal Antibodies Small Molecules Approximately 80% of projects in past 2 y Analytical Method Development Method development and validation services available Responsible for validation of transfer of all incoming QC methods for Bloomington facility Expertise in cleaning validation limit calculations and method development/validation Development stability studies Lyophilization Process Optimization Research Programs 5 Baxter Confidential Bloomington R&D Known As Baxter Lyophilization Center of Excellence DSC Thermogram of EC90 Endotherm Up 20 W/g 2 W/g Heat Flow, W/g We characterize APIs by thermal analyses and freeze-dry microscopy to develop formulations and lyophilization cycles -30 We use freeze-dry microscopy and FTIR to evaluate formulation effects on protein stability -60 -55 -50 -45 -28 -26 -40 -35 -24 -22 -30 -20 -25 -18 -20 -16 -15 -10 -5 0 5 10 15 20 25 Temperature, °C We coordinate transfer and scale up of labdeveloped product to production freeze-dry operations. Our research programs include mechanisms of heat and mass transfer during freeze-drying, nucleation optimization, process monitoring by Tunable Diode Laser Absorption Spectroscopy Since 2001, 35 peer-review research articles, 3 books, 5 book chapters, dozens of short courses, and 80 presentations at conferences and universities Front Door 1 2 Chamber Test Section Detectors Condenser ~ - 80°C to Vacuum Vacuum Pump H-3236 6 Baxter Confidential Baxter BioPharma Solutions Pharmaceutical Research and Development Tim Paul, Lisa Hardwick, Nathan Pease, Wendy Saffell-Clemmer, Larry Callahan Bloomington, IN Top: Middle: Rhonda Haley,Wei Kuu, Melissa Beard, Mike Hildreth, Karen Abram, Kevin O’Bryan, Elizabeth Oslos, Michael Akers Bottom: Lindsay Stanford, Angie Kruszynski, Nathaniel Fair, Jackie Karty, Greg Sacha, Hoang Mitchell, Dan Staples, Kelly Roby, Steven Nail 7 Baxter Confidential Market segment by therapeutic area and molecule class 45,000 Market Size of Biological 40,000 35,000 mAb Sales 2010 ($m) 30,000 Protein Sales 2010 ($m) 25,000 Sales ($M) Total 20,000 15,000 10,000 5,000 0 ab Di gy IID logy ase ogy NS ular alth es tor y inal her o l A o se tol C sc he cin ra st Ot co n i a 's ac spi inte n v cri us d em a O o o i en V Re tro d tio H d r n m a o e ec as C d W G f an In s ete Source: Baxter Analysis Baxter Confidential 8 Current/Future Facts About Biologics • Significant growth 2005 sales: $33B 2005 predicted 2010 sales: $82B 1 out of 4 new drugs introduced in US/EU is a biopharm product • Monoclonal antibodies (MoAbs) $30B of 2010 sales expected to be MoAbs > 200 MoAbs in clinical development right now • About half of current and new biologic products require lyophilization • Many of these products will be self-administered • Obviously, there is a huge market potential for simple, costeffective devices to be used in home health care to prepare and deliver lyophilized biologics (and other lyo products) Especially if product is for chronic health care 9 Baxter Confidential Best Known (Best Selling) Lyophilized Biologics (Biopharmaceuticals) Product Brand (Indication) Company 2009 U.S. Sales Enbrel (Arthritis) Amgen $6,580,000,000 Remicade (Arthritis, Crohn’s) J&J $5.934,000,000 Herceptin (Breast cancer) Genentech $4.890,000,000 7 Human Growth Hormone Brands (Growth hormone Pfizer, Novo, Lilly, Genentech, Serono, Sandoz, Ipsen $2,886,000,000 Avonex (Multiple sclerosis) Biogen Idec $2,323,000,000 Advate (Hemophilia) Baxter $2,058,000,000 Betaferon (Muliple sclerosis) Berlex/Bayer/Merck $1,649,000,000 Total Biologic Sales --- deficiency) $91,780,000,000 10 Baxter Confidential Lyophilization • The terms “lyophilization” and “freeze-drying” used interchangeably • Started in the 1930s, importance grew in WWII • Lyophilization is the conversion of a liquid to a solid through the process of sublimation • A sterile solution is prepared, filled into primary containers, placed into a freeze-dryer, and frozen • The solvent in the solution is removed by directly converting it from frozen ice to water vapor. • What remains in the container are the solute components in the solid state containing very low residual moisture (typically 0.5-2.0%). 11 Baxter Confidential Schematic Overview of Processing Solution and Freeze-Dried Biopharmaceutical Dosage Forms Dispense raw materials (active and excipients) Prepare solution in appropriate Thaw and pool mixing tank (add ingredients to Water For Injection) Wash and sterilize active biopharmaceutical primary containers and closures Add active to solution, ISO 8, Grade D, pH adjustment, final QS Class 100,000 This is formulation bulk solution ISO 5, Grade A Sterile filter formulated Class 100 bulk solution Aseptically fill formulated bulk solution Transfer to Freeze-dryers into primary package and stopper and lyophilize (partial stopper if product is to be freeze-dried Fully insert stopper, remove from freeze dryer Apply aluminum overseal Storage at appropriate 100% inspection temperature (usually 2-8ºC) Baxter Confidential Label, sec package, storage, distribution 12 Preparing Product for Lyophilization Prepare the sterile solution—compound, mix, filter Fill into containers, typically vials Partially insert a special designed rubber closure onto the vials Aseptically load the vials into a freeze dry chamber Freeze every single solution in every vial below a pre-determine critical temperature Using appropriate application of temperature and pressure, sublime the ice from the product Using further application of temperature and pressure, remove the necessary amount of bound water from the product Automatically stopper the vials, neutralize the chamber Aseptically remove the vials from the chamber and apply aluminum seals Baxter Confidential 13 Today’s State of the Art Technology Uses Automated Systems To Transfer Product From Production Line Into the Freeze-Dryer 14 Freeze-Dryer Subsystems (What Must Be Operating Smoothly and Maintained for Lyophilization Process To Succeed?) • • • • • • • Heat Transfer System Refrigeration System Vacuum System Stopper-in-Place System Clean-in-Place System Control System Loading/Unloading System Typical Batch of a Lyophilized Biopharmaceutical Product Worth Several Million $ Baxter Pharmaceutical Solutions 15 Baxter Confidential Courtesy of Samir U. Sane, Ph.D., Genentech, Inc. 16 Baxter Confidential Product temperature lower than shelf temperature during primary drying because energy is consumed as ice sublimes to vapor. 17 Baxter Confidential Flow of Vapor from Chamber to Condenser T T P Vacuum Pump Water Vapor Flow Door Product Chamber Condenser Chamber Connecting Duct Condenser Coils Mushroom Valve (open position) Shelves with Vials 18 Baxter Confidential Schematic of Heat and Mass Transfer in the Freeze Dryer Temperature difference between chamber and condenser and pressure differential Heat Transfer Conversion of solid (ice) to vapor in chamber called sublimation Mass Transfer between solution in vials and vacuum pump drives ice out of vial and onto the condenser Vacuum Pump ΔP Dry Cake Sublimation Front Frozen Solution Thermal Fluid Condenser Pressure gradient between sublimation front and chamber Shelf Thermal fluid circulates within the shelves to control temperature in chamber Baxter Confidential 19 Desired Freeze Dried Product Characteristics Intact cake Sufficient strength Uniform color Sufficiently dry Sufficiently porous Sterile Free of pyrogens Free of particulates Chemically stable—both in dry state and after reconstitution 20 Baxter Confidential Advantages of Lyophilization Removal of water at low temperature Ease of reconstitution Compatible with aseptic operations More precise fill weight control Done properly, the freeze-dried solid has relatively high specific surface area, which promotes rapid, complete reconstitution 21 Baxter Confidential Disadvantages of Lyophilization • The drug may not be stable as a freeze-dried solid • Many biological molecules are damaged by the stresses associated with freezing, freezedrying, or both • Not all solutes can be freeze-dried to form a pharmaceutically acceptable cake • Cost may be an issue, depending on the product 22 Baxter Confidential Common Lyophilized Products • Pharmaceuticals – large and small molecules • Bacteria • Viruses • Vaccines • Plasma • Small Zoological Specimens (Taxidermy) • Fruit • Coffee • Flowers • Water-Damaged Documents 23 Baxter Confidential Main Challenges of Lyophilization • Development of formulation that meets all the necessary critical product attribute requirements (quality appearance, potency, stability, recon time, etc) • Accurate determination of the “critical temperature” of final formulation necessary to determine conditions of lyophilization cycle (Tg’, Te, Tc) • Establishment of temperature, pressure, and time cycle settings that can achieve best product quality in shortest possible time • Transfer and scale-up of lab-developed process to production scale process • Keep all the equipment running smoothly • Special challenges in product development of lyophilized biologic formulations and cycles 24 Challenges in Lyophilization of Protein Pharmaceuticals Baxter Pharmaceutical Solutions 25 Baxter Confidential Challenges in Lyophilization of Protein Pharmaceuticals • Measurable differences in recovery of activity can be associated with differences in the thermal history of freezing • Some proteins can be subject to overdrying; that is dryer is not necessarily better • Stability of the freeze dried solid is often a concern. Most freeze dried proteins require refrigerated storage. • Solid state stability can be affected by small differences in residual moisture content. Baxter Confidential 26 Why Does Lyophilization Take So Long? • Sometimes, the properties of the formulation require that the temperature be very low, often below –30oC. This decreases the driving force • The heat required is very high, and heat transfer in freeze drying is very inefficient • Resistance to mass transfer – transport of water vapor from the sublimation front through the porous bed of partially dried solids – can be significant. • Huge batch sizes, takes time to complete the 3 stages of lyophilization Process Data for Representative Freeze-Dry Cycle 30 300 20 250 10 200 -10 -20 150 -30 Thermocouples 100 -40 -50 50 -60 -70 0 0 10 20 30 40 Time (hours) 50 60 70 Pressure (mTorr) Temperature (°C) 0 Final Comments • Roughly 50% of all commercial biologic (therapeutic protein products) are lyophilized. • Lyophilization technology and the expertise to use it are vital to the ability of the biopharmaceutical industry to prepare and market life-saving injectable medicines • Lyophilization is the most challenging (and most expensive) of all sterile product manufacturing unit operations 28 Baxter Confidential Acknowledgements • Thanks to all my Baxter R&D colleagues for the great collegiality we have and what makes my job so enjoyable. • Thanks to the following individuals for providing some of the slides I showed Dr. Steven Nail Ms. Lisa Hardwick Ms. Wendy Saffell-Clemmer 29 Baxter Confidential