Analysis of Spark Ignition Engine Management System

advertisement

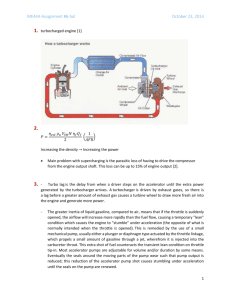

Analysis of Spark Ignition Engine Management System James Bower Josh Duke Casey Fisher Engine Management System Engine Management System Basics Advantages of EFI Future Trends The Brains of the Car Electronic Control Unit or ECU Small computer connected directly to engine Monitors engine parameters through the use of sensors Manages throttle control, ignition, fuel injection, and power Fuel Mapping Through the use of the ECU data and computer programs the engine can be mapped depending on speed and load of the engine. Fuel and timing settings can be adjusted using these maps to achieve maximum performance from the engine. Crank Sensor Determines speed of engine Consists of toothed wheel and an inductive pickup Sensor pulses and creates a magnetic field Depending on location of wheel, changes magnetic field strength From magnetic strength the ECU can tell the exact crank position and speed Throttle Position Sensor Determines the load on the engine Two types: 1) Electronic accelerator pedal Senses force applied to pedal and opens throttle body accordingly 2) Direct linkage Uses a linkage between pedal and throttle Mass Airflow Sensor Current setup uses hot wire method Heated wire placed in venturi section and air flows over wire and cools Measures current required to keep at a constant temperature ECU converts voltage drops into mass airflow Lambda Sensor (Oxygen Sensor) One of the most important components of the engine management system This device is extremely important in fuel conservation and emissions control The amount of oxygen present in the exhaust stream is a direct result of the air/fuel ratio Oxygen Sensor - How it Works Sensor consists of two electrodes, one exposed to air and the other exposed to the exhaust gases Difference in partial pressures of oxygen produces a voltage The ECU reads how much fuel should be injected based on the voltage Rich mixtures contain little free oxygen Lean mixtures contain considerable free oxygen Temperature Sensor Temperatures measured with a sensor known as a thermistor A thermistor is a resistor made of a semiconductor material whose electrical resistance changes with temperature Pressure Sensor Used to monitor intake manifold and ambient pressures Measured by semiconducting silicon diaphragm that separates two chambers Pressure change causes diaphragm to flex When diaphragm flexes cause resistance of material to change ECU monitors voltage change Knock Sensor Sensors alert ECU when vibrations are detected in the cylinder Knock sensors contain a piezoelectric crystal Crystal produces an electric signal when subjected to physical stress due to engine knock. ECU responds by retarding or advancing ignition time EFI Systems Advantages Improved fuel distribution Engine power increases by average of 10 percent Faster acceleration resulting from direct delivery of fuel to the cylinder Leaner air/fuel ratios better fuel economy reduced exhaust emissions Decreased engine knock Elimination of inlet manifold backfiring and icing EFI Systems Disadvantages Cost More vulnerable than carburetors Require clean fuel and air to operate correctly Dirt could cause significant damage to system Future Trends Replacement of mechanical and hydraulic linkages with purely electrical systems Electronically controlled valve systems Faster opening and closing times Minimal impact forces Optimized fuel consumption and engine power Implementation of direct fuel injectors Increased fuel efficiency Reduced emissions Drive-by-wire chassis Electronically controlled breaking, steering, and shifting Shortened braking distance Improved vehicle stability Lower maintenance costs Potential for remote diagnosis and maintenance Conclusion The electronic fuel management system of today’s engines is a revolutionary design that works to maximize engine performance while reducing emissions. This new technology allows for changes in the engine while it is running to achieve peak performance. These systems will only continue to improve as technology advances.