Pfizer Little Island Fiona Hughes

advertisement

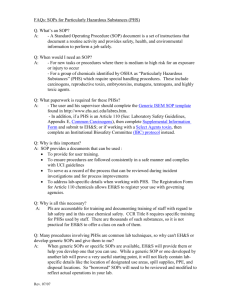

Fiona Hughes, Pfizer, Little Island Learning Council Seamus Fives, Liam Brennan, Deirdre O’Brien, Gerard O’Riordan, Rachael Buckley, Fiona Hughes, Eoin Galvin, Declan O’Riordan, Shane Cullinan. Interaction Training System Lead 100% Fiona Hughes Training Coordinators Plateau System Super User Declan O’Riordan Fiona Hughes Production Declan O’Riordan Production –100% Declan O’Riordan Maintenance % Noreen Quinn QC Catherine Sisk EHS Jacqui Walsh HR/Finance Patricia O’Donoghue Department Training Facilitators SOP Document Controllers Technical Services Deirdre Furney QA Pauline O’Leary GMP/Quality Systems Fiona Hughes Automation Wille Power Engineering (Projects) HR Noreen/Rosario Supply Chain/Warehouse Shane Cullinan Right First Time Gerard O’Riordan Lab Systems Frank Kenny Maintenance/Utilities Noreen Quinn Engineering % Rosario Cronin Supply Chain Warehouse Shane Cullinan EHS Jacqui Walsh Learning and Development Eoin Galvin Enabling Applications Yvonne Cohen Trainers SMEs Buddies Technical Services PASG – Deirdre Furney QA Pauline O’Leary QC & QC Tech Support Catherine Sisk EHS Jacqui Walsh Finance – Patricia O’Donoghue Learning Council Seamus Fives, Liam Brennan, Deirdre O’Brien, Gerard O’Riordan, Rachel Buckley, Fiona Hughes, Eoin Galvin, Declan O’Riordan, Shane Cullinan. Paper training records – filed by SOP name Transcribed data to a database errors No standard course names numbers – duplicates, poor traceability Training was done as SOPs were updated every 3 years No formal definition of SOP Read and Understand, Course Instructor Led or On the Job Training OJT Cross checked old vs new system 3 years of data was uploaded manually Introduced an electronic Learning Management System – Plateau Put together Job Function Curriculum JFC for all colleagues Verified data was correct - corrected Training % complete was 37% - planned to close Training % complete measured every month on Quality Metrics board Ran reports for % complete by Dept Person Item Analysed largest gaps Planned to close SOP Read & understand – online link to Documentation system + paper training record Course Instructor Led - Scheduled 2 weeks of training – lunchtime sessions + paper training record Assessments in place for some course e.g. GMP Refresher training Assessments JFC Creation & review Training Policy Training Methods Induction Overarching document defines that training system is made up of: Induction Job descriptions Job Function Curriculum Methods of training delivered Importance of Training Buddy system – point of contact Booklet for new starter Overview of systems and access Map of site Safety Policy Sports and social aspects Aimed as reference book Defines types of training and when to use SOP Read and Understand Course Instructor Led On The Job Training – OJT ◦ Observe ◦ Assist ◦ Be Observed Core JFC Job Specific JFC Template for JFC & format Quality, safety, technical considerations Revision Control Review to reassess content All SOPs will have assessment questions Assessment in body of SOP & electronic – gets approved by Dept, QA and EHS Minimum of 3 questions per SOP Multiple choice to align with electronic system One set of questions for SOP & Course Assessment can be done electronically or on paper Clear, grammatically correct questions No trick questions Mix up the position of the correct answer Ensure all answers are the same length approximately (same no. of words) Avoid “All of the Above” & “None of the above” answers For SOP Read and Understand Trainee can Log on to LMS Open up SOP – online link Read SOP Take assessment online Sign training record electronically Pass rate is 100% Assessments in SOP and electronic for LMS 2 attempts at assessment If trainee fails, trainee must go to SME/Instructor for instruction Trainer delivers training course Trainee may use case studies, group exercise Use assessment in SOP after training complete All trainees are given opportunity to review Q&A and correct any wrong answers Instructor signs off Trainees sign electronic training record – online, gaps closed immediately, no transcription errors, no paper gets lost Observe x times Assist x times Be Observed x times Instructor & trainee sign off when the trainee is competent and has demonstrated 1)Increase in % Training Complete: 37% complete in Apr’08 96% Mar’10 2) Self Management of training: 410 SOP Read & Understand items are set up online on LMS (~500 SOPs) 6,649 SOP gaps closed by colleagues online 9,913 Course gaps closed in 2009 Very successful 18 months! Launching in 2010 Auto-attendance on LMS Allows us to close gaps immediately – log on to LMS to create electronic training record Update LMS through our SOP System Reduce need for paper forms – all new and revised SOPs will be updated on LMS automatically Scheduled offerings on LMS Plan training, use as a calendar and review at end of year Assessments in place for all SOPs Questions must be to high standard Must test knowledge Must keep questions up to date in future JFC Review for all JFCs - 200 Need to review JFCs for content May create new JFCs / smaller JFCs / phased basis Scheduled offerings on LMS Plan training, use as a calendar and review at end of year Optimise use of LMS