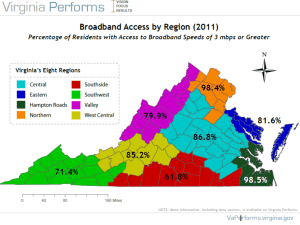

View the Powerpoint

advertisement

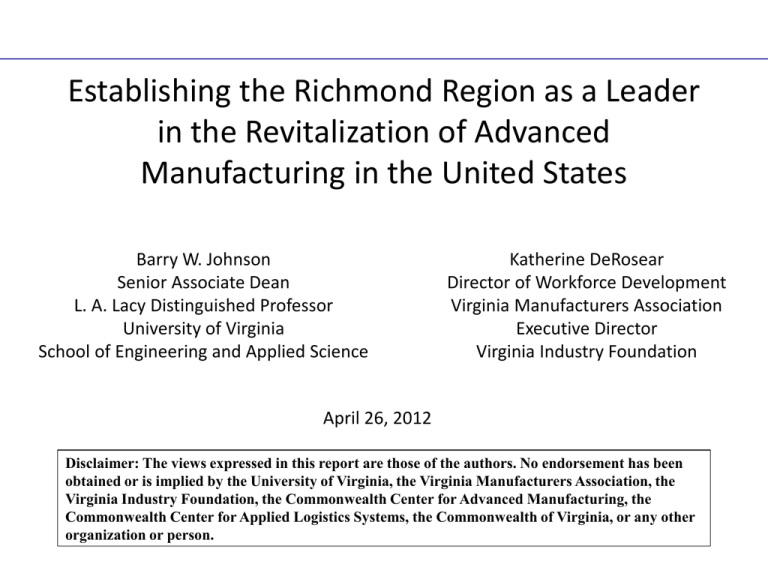

Establishing the Richmond Region as a Leader in the Revitalization of Advanced Manufacturing in the United States Barry W. Johnson Senior Associate Dean L. A. Lacy Distinguished Professor University of Virginia School of Engineering and Applied Science Katherine DeRosear Director of Workforce Development Virginia Manufacturers Association Executive Director Virginia Industry Foundation April 26, 2012 Disclaimer: The views expressed in this report are those of the authors. No endorsement has been obtained or is implied by the University of Virginia, the Virginia Manufacturers Association, the Virginia Industry Foundation, the Commonwealth Center for Advanced Manufacturing, the Commonwealth Center for Applied Logistics Systems, the Commonwealth of Virginia, or any other organization or person. Presentation Outline • • • • • • Introduction Trends Driving Industry Investment Technology Creation and Commercialization Advanced Manufacturing Innovation Zone Workforce Development Recommendations for the Richmond Region 2 Introduction Advanced manufacturing is the integration of technology, processes, policies, and people to produce complex products in the most costeffective, flexible, and efficient way. COPYRIGHT © 2010 THE BOEING COMPANY Smith, 7-April-2011, ESASI-Lisbon | 45 3 Trends Driving Industry Investment • • • • • • Automation – machines can be located anywhere Logistics – supply chains and customers Workforce – higher skill sets required Currency exchange rates – dollar is important Governmental policies – taxes and export control Technology – seamless access to new ideas Result – Advanced manufacturing facilities will be located based mainly on geography and workforce 4 between basic research and commercialization and to accelerate the introduction of new echnologies into the marketplace. The CCAM goal is to greatly improve manufacturing Technology Creation and Commercialization Technology Readiness Levels (TRLs) 1 Through 9 New Ideas Collaborative Generic 1 2 3 4 5 6 7 8 9 Basic Research and Technology Creation Application Development and Proof of Concept Product Development and Commercialization Universities and Research Labs Excel at Levels 1-3 “Valley of Death” Companies Excel at Levels 7-9 Focus of CCALS Figure 1: The Technology Development Pipeline 7 New Products and Services One Agreement Covers All Three Directed 5 Advanced Manufacturing Innovation Zone 6 First Factory at Crosspointe • $170 million investment in first 180,000 square-foot facility • 130 jobs in first facility • Disc manufacturing for engines used in Boeing 787, Airbus A380 and A350 XWB • Future investments growing to $500 million and 500 jobs • 1,000 acres of land for future development First Rolls-Royce Factory at Crosspointe Crosspointe 7 Commonwealth Center for Advanced Manufacturing • Bridge the gap between fundamental research and commercialization – Accelerate technology into markets – Demonstrate on real problems • Foster collaboration among diverse industry sectors – Directed Research for the exclusive proprietary benefit of a member – Generic Research for the benefit of all members • Lower R&D costs for member companies – Shared facilities and personnel – Shared pre-competitive research • Train next generation of technology leaders – Provide market ready experience – Connect industry with students 8 CCAM Applied Research Facility CCAM Ground Breaking Event March 31st 2011 Facility Update – 4/16/12 Photos • 60,000 square foot facility Front View • $3.975 million from U.S. EDA • $2.5 million from Tobacco Commission • $15 million from Virginia’s ARRA bonds • Contractor selected and underway • On schedule for completion September 2012 9 Expansion Plans Additional acreage available Initial CCAM Building Career Center High Bay Expansion 10 Workforce Development Source – 2007 Skilled Trades Gap Analysis 11 Workforce Development Education and Training Curricula K-12 Schools Community Colleges Universities Workforce Pipeline Training Centers Workforce Readiness Levels CCAM Industry Members Future Jobs and Required Skills CCAM Workforce Team Advanced Manufacturing Industry Assessment Methods and Analysis Global Standards and Best Practices 12 Recommendations • Integrate Virginia Commonwealth University (VCU) into CCAM and CCALS. • Engage the Richmond Region’s companies in CCAM and CCALS. • Create a jet engine test cell at the AMIZ to spur research and industry growth. • Implement the workforce development program presented in this report. • Create an advanced manufacturing workforce academy as part of the AMIZ. • Create a Governor’s School for advanced manufacturing as part of the AMIZ. • Create the Advanced Logistics Innovation Zone (ALIZ) around CCALS. • Create a network of CCAM-like centers each focused on an industry sector. 13 Questions Contact Information Barry W. Johnson University of Virginia b.johnson@virginia.edu Mobile: 434-825-5686 14