Today`s Topic: “Operations” - Stevens Institute of Technology

advertisement

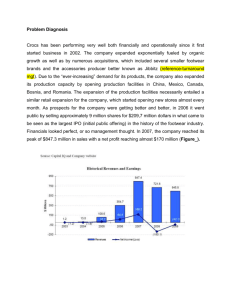

Today’s Topic: Operations The Manufacturing, Logistics and Service functions, and their relationships to technical jobs -or“if you can’t produce and deliver it, it’s unlikely that anyone will pay you any money” Course Schedule The Marketing Function (Lenovo) Sales & Sales Channels (GolfLogix) Internet-based Marketing (HubSpot) R&D: Product Development (Guidant) Operations (Crocs) Product Launch (Invisalign) Final Exam on Product Launch (Emotiv) Last Class & Final Exam Product launch: decisions upon launching a new product (Invisalign case); and summary of key learnings from the course Final exam: decisions on product launch (Emotiv case)…..Dec 20th , 1 – 5pm Operations The function of creating, delivering, and servicing a company’s products and/or services….. includes all but designing, marketing and selling them Learnings: Operations Operations functions: manufacturing, logistics & service Characteristics of world-class operations processes The Operations Balance Impacts on operations: marketing, sales, R&D The Operations Balance COGS Inventory Customer Service The Basic Operations Flow Sales forecasts are given by sales (or marketing) to manufacturing…… Manufacturing produces products (“finished goods”)and spare parts (“spares”) ………and/or delivers the service (ops)…… Logistics (or “distribution”) handles physical distribution to end-customers and/or channels, and is responsible for delivery of spare parts and repair services….. and everyone blames Ops if anything goes wrong! Operations: Short Term Issues Cost of Goods/Cost of Service Production scheduling Manufacturing yield/quality/cycle time Inventory management Logistics efficiency/cost Returns and repairs management Customer service quality Operations: Longer Term Issues In-house or outsourced? Capacity planning: building capacity (just) in advance of when it will be needed, with minimum capital Investing in process technology Building supporting IT systems Regularizing the new product introduction (NPI) process Manufacturing Costs Depend on……. Capacity utilization Capital costs (depreciation on capital) Process technology/yield Cycle time, set-up intervals, run volumes Product designs !! Materials costs (BOM) NPI process efficiency Operations’ Challenge is to Balance…. COGS: COP and COS (cost of product manufacture, cost of service, and logistics expense) Inventory (full-stream: materials, work-inprocess, finished goods, spare parts) Customer service (delivery/response intervals, and quality of services) The Operations Balance COGS (COP,COS) Inventory Customer Service Operations is impacted by “inputs” from……. Marketing Sales R&D and others (IT, finance, HR, … ) Marketing: Inputs/Impacts Product line/model breadth Cost/COGS targets Product quality targets New product strategy (big-bang or incremental/inch-up) Customer service requirements Sales promotions/incentives Sales forecasts (long-run) Sales: Inputs/Impacts Sales forecasts (short-run) Warranty/return management Commitments to customers Quality of installation/maintenance Accuracy of customer orders Ability to “level out” sales volume R&D: Inputs/Impacts Product designs (for cost and service) Design changes/modifications Product materials/components Quality and timeliness of “hand-offs” Process engineering efforts (or not) Role in manufacturing engineering Support for concurrent engineering Readings Can Marketing and Manufacturing Coexist? -read to understand the 8 issues listed in the article’s Exhibit Crocs: Revolutionizing an Industry’s Supply Chain -- an example of the importance of Operations in the success of a business Assignment In what ways can technical people (R&D, technical sales, etc) assist with the resolution and/or minimization of the marketing-manufacturing issues cited in the first reading? Provide one thought/example for each of the 8 issues in the exhibit in the “Coexist” reading. What are Crocs’ competitive advantages? Which of these are related to its operations function? To what extent do each of these growth strategies leverage Crocs’ competitive advantages: (a) internal manufacturing of raw materials used in compounding, (b) internal development of new products, (c) acquiring companies to get new products, and (d) acquiring companies to get new customers? Assignment: R&D Impacts on…? Capacity planning Production scheduling Logistics/distribution Quality assurance Breadth of product line Costs (COGS: COP and COS) New Product Introduction Customer service Can Marketing and Manufacturing Coexist? Problem Area Typical marketing comment Typical manufacturing comment Capacity planning and long-range sales forecasting “Why don’t we have enough capacity?” “Why didn’t we have accurate sales forecasts?” Can Marketing and Manufacturing Coexist? Problem Area Typical marketing comment Typical manufacturing comment Production scheduling and shortrange sales forecasting “We need realistic customer commitments and sales forecasts that don’t change like wind direction” “We need faster response. Our lead times are ridiculous.” Can Marketing and Manufacturing Coexist? Problem Area Typical marketing comment Typical manufacturing comment Delivery and physical distribution “Why don’t we ever have the right merchandise in inventory?” “We can’t keep everything in inventory” Can Marketing and Manufacturing Coexist? Problem Area Typical marketing comment Typical manufacturing comment Quality assurance “Why must we always offer options that are too hard to manufacture and that offer little customer utility?” “Why can’t we have reasonable quality at reasonable cost?” Can Marketing and Manufacturing Coexist? Problem Area Typical marketing comment Typical manufacturing comment Breadth of product line “Our customers “The product demand line is too broad variety” – all we get are short, uneconomical runs.” Can Marketing and Manufacturing Coexist? Problem Area Typical marketing comment Typical manufacturing comment Cost control “We can’t provide fast delivery, broad variety, rapid response to change, and high quality at low cost.” “Our costs are so high that we are not competitive in the marketplace” Can Marketing and Manufacturing Coexist? Problem Area Typical marketing comment Typical manufacturing comment New product introduction “New products “Unnecessary are our design changes lifeblood” are prohibitively expensive.” Can Marketing and Manufacturing Coexist? Problem Area Typical marketing comment Adjunct services “Field service such as spare costs are too parts inventory high.” support, installation, and repair Typical manufacturing comment “Products are being used in ways for which they weren’t designed.” Crocs case: questions What are Crocs’ competitive advantages? Which of these are related to its operations function? To what extent do each of these growth strategies leverage Crocs’ competitive advantages: (a) internal manufacturing of raw materials used in compounding, (b) internal development of new products, (c) acquiring companies to get new products, and (d) acquiring companies to get new customers? Core Competencies vs. Competitive Advantages Core Competencies Competitive Advantages - capability - process - skill - position Crocs Supply Chain Characteristics Global manufacturing Vertical integration “Postponement” (JIT production) Warehouses at production facilities “Excess” capacity and inventory Simple products (initially) Short lead times Production throughout selling season Growth Alternatives internal manufacturing of raw materials used in compounding internal development of new products acquiring companies to get new products acquiring companies to get new customers Identifying Competitive Options Products Current products Current Position Current target customers Customers Competitive Options Protect & defend current customer/product segment Increase market share in current segment Selectively extend (whole) product offerings Selectively extend target customer set Become a broad-line supplier Our Last Assignment: Product Launch Invisalign A new technology ( ~ 2000) for aligning teeth Product Launch Assignment: Align Technology in 2001 Invisalign straightens teeth via a series of clear plastic retainers designed and made specifically for each patient Higher price and higher COGS than traditional metal braces, but “better” Product available for about 2 years Annual revenues ~$50M but OI ~($100M) Adoption rate by orthodontists is insufficient to support future growth Arguably, the product needs to be “re-launched” Assignment for Next Week Which of the three end-customer (patient) segments identified should be Align’s target? Why? Which of the promotion and sales tasks (promotion, selling, fulfillment, service) should be done by Align? By the dentists? By the orthodontists? What are the orthodontist’s “channel economics” for Invisalign vs. standard braces? What barriers are preventing increased adoption of Invisalign by orthodontists? How should Invisalign be positioned with orthodontists? (write a positioning statement) By what methods should Invisalign be promoted to dentists? To orthodontists?