Presentación de PowerPoint - Industrial Technologies 2012

advertisement

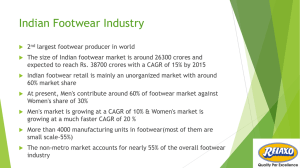

INESCOP Footwear Technological Institute Use of advanced tools for multilocalized design and manufacturing in the footwear industry Dr. Enrique Montiel Industry of Design-Based Products: Creating Value through Customization 1 What is INESCOP? Independent service organisation. Founded in 1971. Non-profit making institution. More than 500 associated companies. 2 Technology Centre INESCOP works as a Technology Centre that supports footwear industries to develop scientific and technical activities that cannot be undertaken by themselves. INESCOP owns 20 patents on different systems, most of them transferred to the industry for exploitation. INESCOP has participated in over 90 EU projects since 1986. 3 INESCOP’s services Testing services, quality control. Technology development. Applied research. Industrial and fashion design. Environment. Training. Information. 4 Close to the factories Network of laboratories: 6 technical units and 1 affiliated centre 5 The world footwear sector Value of the world footwear market: 1 246 Billion Euros 6 1All data obtained from World Footwear Yearbook 2011 The world footwear sector In 2010 for the first time ever World footwear production exceeded: 7 20 Billion Pairs The world footwear sector Manufacture is heavily concentrated in they produce 87% of all the pairs of shoes produced worldwide European Countries produce only 8 Asia: 4% of world footwear pairs The European footwear sector Europe: 20% of world shoe consumption destination of 45% of world imports Europe exports only 9 11% of world total footwear The European footwear sector 9 European countries are in the top15 world footwear exporters Spain Italy Portugal 10 23% Share of all footwear exported in the world The Spanish footwear sector The Valencian Region is the hub of the Spanish footwear industry, although it is also present in areas such as Castilla La Mancha and La Rioja. 11 The Spanish footwear sector In 2011, Spain exported to China footwear with an average value of 46.43€ Footwear average value 40.2€ Exported 12 5.9€ Imported The Spanish footwear sector The Spanish industry has been able to increase its exports to the most important European markets, but lost some share in USA. 13 The Spanish footwear sector Imports grew rapidly, both from China and from European markets such as Italy and France. 14 The Spanish footwear sector Footwear exports concentrate in leather shoes, while imports concentrate in cheap rubber & plastic ones. 15 The product problem Life-cycle 10 y. 0.5 y. 80€ Price 12,000€ Short life cycle + low price ( + extremely short series: customisation) 16 The time-to-market problem Typical design, manufacture and commercialisation cycle …but there are other cycles 17 The time-to-market problem One season/year design, manufacture and commercialisation cycle e.g. Kelme (sports footwear) 18 The time-to-market problem Continuous design, manufacture and commercialisation cycle e.g. Tempe (Zara) 19 The communication problem Lasts Soles Heels 20 Prototypes Headquarters Design Prototypes Lasts Heels Soles Manufacturing Distribution Manufacturing Possible solutions Flexibility Speed at the design stage at the manufacturing stage Accuracy Integration: seamless communication of teams Marketing support: new means 21 Proven experience 22 Case 1: Kelme Problem: to develop a high performance FUTSAL shoe, in collaboration with Michelin, reducing the development/manufacturing time. 23 Case 1: Kelme Solution: to integrate new biomechanical paradigms, 24 All shoe images in this presentation are Virtual Models Case 1: Kelme Solution: to integrate new biomechanical paradigms, new materials 25 Case 1: Kelme Solution: to integrate new biomechanical paradigms, new materials and new sole design in a digital model, 26 Case 1: Kelme Solution: to integrate new biomechanical paradigms, new materials and new sole design in a digital model, using an integrated knowledgebased CAD/CAM solution. 27 Case 2: Sacha London Problem: to add value to the point-of-sale, and to increase mass media impact of the brand. 28 Case 2: Sacha London Solution: to offer the chance to customise 29 Case 2: Sacha London Solution: to offer the chance to customise all the footwear collection, 30 Case 2: Sacha London Solution: to offer the chance to customise all the footwear collection, using a tablet 31 Case 2: Sacha London Solution: to offer the chance to customise all the footwear collection, using a tablet and an web-based online customisation system (iShoe), 32 Case 2: Sacha London Solution: to offer the chance to customise all the footwear collection, using a tablet and web-based online customisation system (iShoe), and offering the possibility to test the model in an Virtual Mirror (iMirror). 33 Case 3: Tempe (Inditex) Problem: complex and multifactorial operational environment, with multiple conditional factors. …some data: 2 INDITEX has 5,618 shops, opening at least 1 new shop/day. TEMPE designs, manufactures and distributes footwear for all INDITEX brands. 34 2 April 2012 published data, INDITEX group Case 3: Tempe (Inditex) Footwear accounts for 10% of INDITEX’s total sales. Footwear is INDITEX’s most profitable product. 35 Case 3: Tempe (Inditex) 60 million shoes/year (1 billion €). 36 Case 3: Tempe (Inditex) TEMPE’s Design Center employs 110 designers, working on the two-season collections and the out-of-season designs. 37 Case 3: Tempe (Inditex) Footwear is worldwide manufactured in 200 38 factories. Case 3: Tempe (Inditex) Footwear design and production has 2 main seasons, but they also maintain a continuous design/manufacturing cycle for the whole year (to cope with emerging trends & oversales). 39 Case 3: Tempe (Inditex) Every year 25,000 prototypes are designed and manufactured… …only 8,000 of them are selected for final production. 40 Case 3: Tempe (Inditex) Solution: To use INESCOP’s integrated CAD/CAM solutions, starting from the shoe design phase. 41 Case 3: Tempe (Inditex) Solution: To use INESCOP’s integrated CAD/CAM solutions, starting from the shoe design phase. To exchange information using compatible data files between design and production centres: components (lasts, heels, soles) and whole footwear. 42 Case 3: Tempe (Inditex) Solution: To use INESCOP’s integrated CAD/CAM solutions, starting from the shoe design phase. To exchange information using compatible data files between design and production centres: components (lasts, heels, soles) and whole footwear. To create hyper-realistic virtual prototypes. 43 Case 4: CallagHan Problem: to add value to their shoes to differentiate them from their competitors. 45 Case 4: CallagHan Solution: to design and develop a casual shoe with an integrated electronic device that records physical activity Result from the FP6 EU Project No. 507378 “CEC-made-shoe. Custom, environment and comfort made shoe” 46 Case 4: CallagHan Solution: to design and develop a casual shoe with an integrated electronic device that records physical activity and is connected to a web-based personal trainer. 47 Case 5: Duna Problem: to allow the integration of customised footwear manufacture in an industrial line of serial production. 48 Case 5: Duna The technology 49 innovation in DUNA New Products Lines All products must be developed according to the European laws for medical devices Specific solutions to integrate different technologies in the production processes Small production lot till the single pair or shoe with specific technical solution against production industrial machines generally studied for simply workout and lots with high volume. New communication systems The large range of technical info on the products to be transferred to end-users, customers and medical world require appropriate communication systems. Special R&D Programs DUNA is official partner of “SSHOES - Special Shoes Movement” European Project Grant agreement no.: NMP-2008-SME-2-R.229261 Case 5: Duna Solution: by means of the research project SSHOES3 (Special Shoes Movement), to develop a completely digital process to manufacture a customised diabetic shoe: Biomechanical analysis (MiniLab). Foot scanning (3D scanner). Activity pattern analysis. Knowledge-based CAD/CAM design. Testing devices. Robotic cell production. 50 3 NMP2-SE-2009-229261, Seventh Framework Programme. Future trends: Seamless integration of functional analysis/biomechanics, material science and comfort issues in CAD/CAM software. Low-cost robotic cells for short series production as well as massive introduction of robotics. Better simulation tools, both for product and processes: VR, AR. Better use of ICT tools: interoperability, embedding Knowledge in products. 51 You are invited… 52 INESCOP Footwear Technological Institute POLIGONO INDUSTRIAL CAMPO ALTO C/ Alemania, 102 03600 ELDA ·ALICANTE· SPAIN Tel. +34 965 39 52 13 - Fax +34 965 38 10 45 E-mail: emontiel@inescop.es http://www.inescop.es 53 54