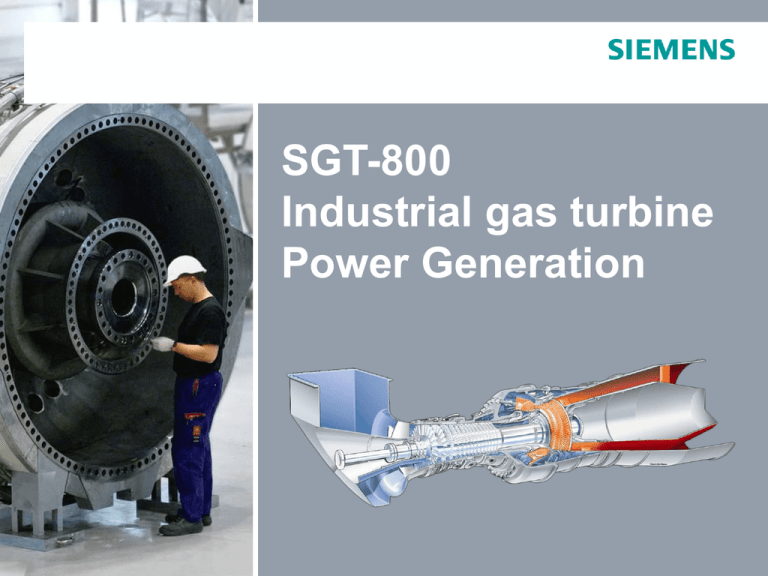

SGT-800

Industrial gas turbine

Power Generation

Please address all correspondence to:

Siemens Industrial Turbomachinery AB; SE-612 83 Finspong; Sweden

© Siemens Industrial Turbomachinery AB

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

Page 1

No part of this document may be reproduced or transmitted in any form or by any means, including photocopying and

recording

without the written permission of Siemens Industrial Turbomachinery AB

SGT-800

E O IP

SGT-800 Industrial gas turbine

Contents

Main features, benefits and experience

Performance characteristics

Package design

Core engine design

Maintenance

Reference sites

Page 2

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

Siemens range of Gas Turbines

SGT-800 47MW

State-of-the-art and innovative gas turbines

to meet today’s and tomorrow’s energy needs

Page 3

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Simple and robust for reliable power generation

in the 47 MW-class

Page 4

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Features and benefits

High industrial gas turbine electrical efficiency

Dual fuel low emissions technology

Fuel changeover capability

Stable load rejection capability, <5%

overspeed

Low gas supply pressure, 27-30 bar(a)

High exhaust energy giving excellent

cogen/CC characteristics

Established onsite service concept

Page 5

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Features and benefits

Features

Resulting in

Excellent cogen/CC efficiency

Minimized fuel costs

Low NOx emissions with simple dual

fuel DLE technology

Low NOx emission without water

injection

Flexible maintenance concept onsite maintenance or modular

overhaul

Reliable operation

Predictable service costs

Robust industrial heavy duty design

Low gas pressure requirement

Page 6

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Fleet experience & Worldwide sales

Fleet Experience

Sales by Industry Segment

80

Service introduction year

= 1999

Units sold to date

= 131

Total fleet hours

> 1,300,000

Lead Package hours

> 70,000

30

Fleet Availability

98.2%*

20

Fleet Reliability

99.8%*

70

60

50

40

10

0

Utilities/IPPs

* AF/RF figures based on a 12 month rolling average

Worldwide Sales

Chemicals

Metals

Others

Simple

Cycle

Europe

Combined

Cycle

Latin America

Pulp & Paper

Sales by Application

Asia/Oceania

Middle

East/Africa

O&G/

Refineries

Cogeneration

North America

Russia

Page 7

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Installation locations

1 turbine

2 turbines

3-4 turbines

5-9 turbines

10+ turbines

Page 8

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Contents

Main features, benefits and experience

Performance characteristics

Package design

Core engine design

Maintenance

Reference sites

Page 16

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Simple cycle performance - natural gas

ISO rating - base load

Pe

47 000 kW

S.H.C.

9 597 kJ/kWh / 9096 Btu/kWh

El. efficiency

37.5 %

Exhaust mass flow

131.5 kg/s

/ 289.9 lb/s

Exhaust temperature

544 °C

/ 1,011 °F

Page 17

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

DLE combustion system capability

Burner type

Fuel

50-100% load

NOx @ 15% O2

50-100% load

CO @ 15% O2

Note

Gas burner

Natural gas

≤ 15 ppmv

≤ 5 ppmv

Dry

Dual fuel

burner

Natural gas

≤ 15 ppmv

≤ 5 ppmv

Dry

Diesel No.2

≤ 42 ppmv

≤ 5 ppmv

Dry

Emission Guarantees are issued separately

in each project, depending upon site

conditions, required load range and other

project specific data.

Page 18

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Performance

Factors that affect power output

include

SGT-800-47 Nominal Generator Output and Heat Rate for gas fuel

55

10.5

10.4

10.3

10.2

45

10.1

10

40

9.9

9.8

35

Heat Rate, MJ/kWh

Generator Output, MW

50

9.7

9.6

30

9.5

-40

-30

-20

-10

0

10

20

30

40

Inlet & exhaust system losses

Humidity

Fuel quality/type

Temperature

Altitude

Atmospheric pressure

Compressor Inlet Air Temperature, °C

600

145

590

140

580

135

570

130

560

125

550

120

540

115

530

110

520

105

Exhaust Temperature, °C

Exhaust Mass Flow, kg/s

SGT-800-47 Nominal Exhaust Mass Flow and temperature for gas fuel

150

510

-40

-30

-20

-10

0

10

20

30

40

Compressor Inlet Air Temperature, °C

Page 19

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Cogeneration cycle

11.2 % losses

1-pressure HRSG

51.6 % process heat

Gas Turbine

37.2 % electricity

100 % fuel

Total Efficiency 88.8 %

Page 20

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Combined cycle

11.6 %

losses

Steam Turbine (condensing)

520 deg C

2-pressure HRSG

31 deg C

17.2 %

electricity

31 deg C

Gas Turbine

15 deg C

37.1 %

electricity

27 deg C

100 % fuel

34.1 %

losses

Total Efficiency 54.3 %

Page 21

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800

Steam Raising Capabilities for Gas Turbine

Co-Generation Plant

125

SGT-400

100

75

50

SGT-700

Unfired

Fired

SGT-600

150

SGT-500

175

SGT-100

SGT-200

SGT-300

Steam (tonnes/hr) [12 bar saturated]

200

25

0

0

5

10

15

20

25

30

35

40

45

50

Power (MWe)

Notes:

1. Steam values are indicative only. Actual values depend on site configuration

2. Firing to 850ºC only. Higher firing is available

Page 22

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Performance - combined cycle, natural gas

Condensing operation

Non - reheat, 1 x SGT-800

GT

ST

Auxiliaries

46 000 kWe

21 400 kWe

-900 kWe

Net total

66 500 kWe

Fuel

El. Efficiency

123 800 kJ/s

53.7

SCC-800 1x1

at ISO-conditions including losses

Page 23

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Performance - combined cycle, natural gas

Condensing operation

Non - reheat, 2 x SGT-800

GT

ST

Auxiliaries

Net total

Fuel

El. Efficiency

SCC-800 2x1

92 100 kWe

44 400 kWe

-1 400 kWe

135 100 kWe

248 300 kJ/s

54.4 %

at ISO-conditions including losses

Page 24

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Excellent combined cycle part load efficiency

Part Load Performance Combined Cycle

60

Efficiency, %

55

50

45

40

35

50

60

70

Base Load Power, %

80

90

100

Condensing operation

Non - reheat, 1 x SGT-800

Natural gas fuel

= LHV 46798 kJ/kg

Altitude (sea level) = 1,013 bar

Relative humidity = 60 %

Page 25

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Contents

Main features, benefits and experience

Performance characteristics

Package design

Core engine design

Maintenance

Reference sites

Page 26

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

General Arrangement

Combustion air

inlet filter

Exhaust

Enclosure

ventilation inlet

Enclosure

ventilation outlet

Fire suppression

cabinet

AC generator

Generator cooling

air inlet

Electrical and

Control module

Lube oil cooler

Page 27

Generator air

outlet

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Compact and flexible layout

Small footprint

Dimensions ~27x7 m

Auxiliary equipment on a separate

skid

Standardized

The layout is basically the same

for all applications

Page 28

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Standard reference plant

Combined Cycle Power Plant

Lead time reduction

Proven plant concept

Maintainability

improvement

Long standing relations

with key suppliers

Risk reduction

Availability increase

Page 29

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Contents

Main features, benefits and experience

Performance characteristics

Package design

Core engine design

Maintenance

Reference sites

Page 30

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Designed for reliability

Simple and robust

1-shaft Gas Turbine

Single rotor with tilting pad

type bearings

Cold end drive

Bearing #1 (radial + thrust)

All welded compressor

rotor

Engine inlet

Annular cc with 30 dual fuel DLE burners

15 stage compressor

3 stages variable guide vanes

Bearing #2 (radial)

Annular combustor

Bolted 3-stage turbine

Maintainable

Modular design

On-site maintenance

Drive shaft to gear box

3 stage turbine

Engine exhaust diffuser

6600 rpm

Page 31

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Contents

Main features, benefits and experience

Performance characteristics

Package design

Core engine design

Maintenance

Reference sites

Page 32

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Easy on-site maintenance

Modular build-up for easy

maintenance on site

No need for special

workshops maintenance

Gas turbine can be removed

on rollers through the sliding

door

Removable burners for short

and easy inspection

Vertically split compressor

casing

Page 33

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Maintenance Programme

Basic Maintenance Plan

Level "D"

Level "C"

Level "B"

Level "A"

Operation

Maintenance

10

20

30

40

50

60

70

80

90

100

110

120

Eq. Op. Hrs x 1000

Page 34

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Service in situ

Removal of the turbine module

Page 35

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

Emergency back-up

24-hour telephone

support

Operation support

24/7 emergency phone

On-line remote troubleshooting

Remote Monitoring System

Emergency

gas generator

Emergency resources

Service engineers

Tools & spare parts

Core engine & modules

Service depots

Emergency store

Guaranteed mobilization time

Personnel - 24 hours

Tools, spares, engine & modules to site or to

international freight forwarder within 72 hours

Page 36

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

Remote monitoring (STA-RMS)

Data collection

Decision Support

Reporting

Plant Data:

Operational Data

Diagnostics Experts

Team

Customer

Closed Loop

Service

Risk Mitigation

O&M support

Solutions /

Improvements

Trouble shooting

Page 37

FLEET INPUT

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

Remote monitoring (STA-RMS)

Siemens' system provides...

… our customer with a professional tool for optimisation of operation, i.e.

increased reliability and availability

… built-in OEM knowledge

… access to real and historic data

… monitoring of performance

… monitoring/trending and plotting of vibrations for analysis and diagnostics

… a powerful tool for the continuous improvement process

… the possibility of remote software upgrades without a site visit

Results in a way to optimise operation by storing, analysing and exchanging

information

Page 38

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Contents

Main features, benefits and experience

Performance characteristics

Package design

Core engine design

Maintenance

Reference sites

Page 39

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Combined Cycle application

Riga SCC-800 x 2DH

Riga, Latvia

Combined heat and power plant

supplying electricity and district heating

for the city of Riga. Owned by

Latvenergo, the Latvian national

electricity company

Turn key delivery from Siemens including

two SGT-800's, steam turbine, two

supplementary fired HRSG, auxiliaries

and balance of plant

Handed over to customer on schedule

2005

Nominal power output 140 MW and up

to 150 MWth for district heating

DLE combustors operating on natural gas

Page 40

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Simple Cycle application

MMPA SGT-800 x1SC

City of Chaska, Minnesota, USA

SGT-800 in peaking application located in

City of Chaska, Minnesota, USA

providing power to the Minnesota

Municipal Power Agency

Remote monitoring by an energy services

company located 40 km from Chaska

Dual fuel combustors with DLE meets

the emission limits without water injection

In operation since 2002

Page 41

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

SGT-800 Industrial gas turbine

Solution to worldwide customer demands

Simple and robust design for reliable

operation

Low emissions for environmental

compliance at full and part load

Excellent in combined cycle

Compact layout

Competitive life-cycle cost

Page 43

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

Disclaimer

This document contains forward-looking statements and information – that is, statements related to future, not past,

events. These statements may be identified either orally or in writing by words as “expects”, “anticipates”, “intends”,

“plans”, “believes”, “seeks”, “estimates”, “will” or words of similar meaning. Such statements are based on our current

expectations and certain assumptions, and are, therefore, subject to certain risks and uncertainties. A variety of factors,

many of which are beyond Siemens’ control, affect its operations, performance, business strategy and results and could

cause the actual results, performance or achievements of Siemens worldwide to be materially different from any future

results, performance or achievements that may be expressed or implied by such forward-looking statements. For us,

particular uncertainties arise, among others, from changes in general economic and business conditions, changes in

currency exchange rates and interest rates, introduction of competing products or technologies by other companies, lack

of acceptance of new products or services by customers targeted by Siemens worldwide, changes in business strategy

and various other factors. More detailed information about certain of these factors is contained in Siemens’ filings with the

SEC, which are available on the Siemens website, www.siemens.com and on the SEC’s website, www.sec.gov. Should

one or more of these risks or uncertainties materialize, or should underlying assumptions prove incorrect, actual results

may vary materially from those described in the relevant forward-looking statement as anticipated, believed, estimated,

expected, intended, planned or projected. Siemens does not intend or assume any obligation to update or revise these

forward-looking statements in light of developments which differ from those anticipated.

Trademarks mentioned in this document are the property of Siemens AG, it's affiliates or their respective owners.

Page 44

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP

Please address all correspondence to:

Siemens Industrial Turbomachinery AB

SE-612 83 Finspong

Sweden

© Siemens Industrial Turbomachinery AB

No part of this document may be reproduced or transmitted

in any form or by any means, including photocopying and

recording without the written permission of Siemens

Industrial Turbomachinery AB

Page 45

© Siemens Industrial Turbomachinery AB 2011. All rights reserved.

SGT-800

E O IP