PRI-QPL Presentation - January 2014

advertisement

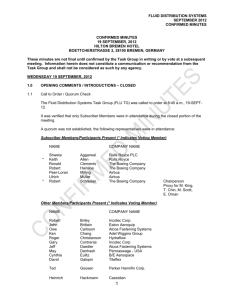

Performance Review Institute Qualified Products Listing January 30, 2014 Definitions • QUALIFIED PRODUCTS LIST (QPL): A listing of products from manufacturers who have received a PRI product qualification to a specific aerospace standard for specific product designations and plant locations. • QUALIFIED PRODUCT GROUP (QPG): A committee mandated by the QPMC responsible for assessing whether manufacturer's products comply with the relevant aerospace standard. The committee is composed of members from Original Equipment Manufacturers (OEMs) and Government Agencies. • QUALIFIED PRODUCT MANAGEMENT COUNCIL (QPMC): The committee that manages the Qualified Product Process/Program. 2 PRI QPL Program Background QPL - A document which lists qualified manufacturers who have met the product qualification test requirements to a specified industry standard for specific part numbers and plant locations 1996 Pilot program 1998 Industry Managed 2014 PRI QPL Program DoD Acquisition Reform Military specifications with QPL’s posed a problem for non-government standards to convert Preserve value-added aerospace specification requirements PRI championed pilot program, with organizational concept SAE committee volunteers Pilot program success PRI QPL program formally established Standard Development Organization (SDO) guidelines created and approved by SAE Aerospace Council - 1999 3 TODAY. . . More than 30,000 products/parts 8 active Qualified Product Groups Purpose of the Aerospace QPL Program • Maintain a list of manufacturer’s critical products where those products have been qualified as meeting specific industry standards. • To manage the review process of submitted data and other materials reviewed by the QPG. 4 Motivation • • Users (OEMs/Government/Airlines) – Collaboration with other OEMs/Government/Airlines – Reduce costs by reduced need for in-house/outside lab testing – Uses consistent qualification procedures/standards – Maximize competition without the loss of quality – Avoid cost associated with maintaining User QPLs (testing, qualification, administration) Suppliers – Typically lower costs than when qualifying products to User standards/specifications – Utilize initial qualification data to a wider industry base – Eliminate redundant testing and qualification processes – Ensure fairness among suppliers – Utilize consistent approach to qualification of product 5 Industry-Managed QPL Structure Policy Executive Leaders •Legal Entity •Set Policy •Provide the Vision Strategic/ Tactical PRI Board of Directors Senior Leaders & Managers •Oversee Operation of QPL Program •Establish & Implement Policy & Procedures •QPG Coordination & Development •Identify, Develop and Deploy Improvement Standards Developing Organization (SDO) Qualified Product Management Council (QPMC) QPGs Technical Experts Determine Requirements Develop Documents Accepts Test Plan and Report Final Decision on QPL Listing Technical Process responsibilities clearly defined 6 Fluid Distribution Systems (G-3) Elastomer Seals (AMS CE) Sealants (G-9) Organic Coatings (G-8) Propulsion Lubricants (E-34) Propulsion Standards (E25) CACRC Advanced Composites (P-17) Standard Technical Committees Knowledgeable Parties With Interest Maintain Technical Standards, Recommended Practices, etc. Role of PRI • Coordinate operations/procedures of the QPMC and QPGs • Coordinate activities throughout the QPG review and report processing • Maintain and Control QPLs • Maintain customer records during and after review Administrator of the QPL program • Maintain confidentiality 7 2014 Board of Directors Stan Adachi Honeywell Aerospace The Boeing Company Richard A. Amato Anna “Graham” Morast Pratt & Whitney, UTC GE Aviation Etienne Galen Andy Page Rolls-Royce plc Snecma (Safran Group) Michael J. Hayward David L. Schutt SAE International Northrop Grumman Aerospace Systems Mario Langlois (Chairman) Junji Tsuji Ishikawajima-Harima Heavy Industries Bombardier Aerospace Tony Maguire Ron Meester Li Wei Aviation Industry Corporation of China BAE Systems PLC Jianqiang Xu January 2014 8 COMAC Role of QPMC • Provide direction for the administration of the PRI-QPL qualification program • Provide an effective administrative structure to manage QPLs utilizing existing task groups, committee’s, etc. and provide feedback to industry in the form of guides or advisories • Coordinate and communicate major QPL activities throughout the industry • Ensure consistency in QPG operating procedures • Resolve appeals of QPG decisions 9 Qualified Product Management Council • Jerry Brown Materials & Processes Engineer Lockheed Martin Aeronautics Co. • Kent DeFranco (Chairman) Materials Engineer, Sr. Staff Lockheed Martin Aeronautics Co. • Ross Downing (Vice Chairman) Principal Engineer The Boeing Company • Alan Fletcher Materials Engineer, Systems Support Div. US Air Force • Robert Hainline Mechanical & Structural Engineer The Boeing Company • Tim Koczanski Defense Standardization Program Office Accurate as of January 2014 • Manuel Koucouthakis Principal Engineer Honeywell • Gary Landry Program Manager, Design Systems Pratt & Whitney • Carl Levandusky General Engineer Naval Air Warfare Center • James Lewis (Secretariat) Program Manager Performance Review Institute • Paul Wittman Certification Manager Middle River Aircraft Systems 10 Policy and Procedures PROGRAM DOCUMENT PD2000 GOVERNANCE AND ADMINISTRATION OF AN INDUSTRY MANAGED PRODUCT QUALIFICATION PROGRAM PROGRAM DOCUMENT PD2001 MANUFACTURER REQUEST FOR PRODUCT APPROVAL AND QUALIFICATION PROCESS 11 Role of Qualified Product Group • Meet and review data in a timely manner as required by procedure • Establish procedures for the review • Review data for conformance to requirements • Define and approve data sources • Disposition each qualification submittal • Forward evaluation reports to PRI 12 Current Qualified Product Groups • • • • • • • • Sealants * (SAE G-9) – Polysulfide, Polythioether and Adhesion Promoters Commercial Aircraft Composite Repair (SAE CACRC) – Composite Repair Materials, Processes and Methods Elastomer Seals * (SAE AMS-CE) – O-Rings, Plate Seals, Gaskets and other Compression Seals Fluid Distribution Systems Components * (SAE G-3) – Couplings, Fittings, Hose, Tubing and Installation Procedures Organic Coatings (SAE G-8) – Primers, Topcoats, Specialty Coatings e.g. Fuel Tank Coatings, Rain Erosion Coatings Propulsion Lubricants (SAE E-34) – Synthetic Turbine Engine Lubricants General Standards for Aerospace and Propulsion Systems (SAE E-25) – Solid Film Lubricant Polymeric Advanced Composite* (SAE P-17) * Require a Nadcap Audit 13 The QPL Process 14 QPL Approval Process – Initial PRI Communicates Request for Additional Information To Supplier Yes Supplier Submits Application And Applicable Data to PRI PRI forwards Submission to QPG QPG Reviews Data Additional Information Requested No Approval Granted 15 As to the Supplier…. • Obtain a copy of the applicable standard at www.sae.org • Obtain a copy of the applicable Program Document at www.eAuditNet.com / Resources / Documents / Public Documents / QPL Programs • Pay special attention to requirements, such as: – – – – AS/EN/JISQ9100 ISO/IEC 17025 Lab QPG witness Test plan requirements per the specification/PD document 16 And then…. • Go to www.eAuditNet.com to initiate a “Project”. • Instructional PowerPoint Document – Resources / Documents / Public Documents / QPL Programs / “QPL User Guide – Supplier” Documents to be marked as Proprietary. 17 The Nadcap Audit Process 18 Nadcap • Nadcap – The leading worldwide cooperative program of major companies designed to manage a cost effective consensus approach to special processes and products and provide continuous improvement within the aerospace and automotive industries. 19 Require a Nadcap Audit • Is a Nadcap Audit required? – SAE Committee determines if the Nadcap Audit is required 20 Information to Request the Establishment of a PRI QPG 21 Primes Involved in the QPG • Determine the structure and relationship between – SAE Committee and – the yet to be established QPG [Minimum of 3 primes required] 22 Key Players • SAE Committee Members Planning to Participate in the QPL Project Reviews – Contact & Company Name 23 Program Information • Number of Suppliers Impacted • Applicable Current Specification Numbers and List of Potential Specifications • Potential QPL Projects (workload) • Timeline for Completion/Publication of the Specification 24 Program Information (continued) • Is an AS/EN/JISQ9100 approved quality system required? • Is it required to conduct the testing at an ISO/IEC 17025 accredited laboratory with applicable scope? 25 Program Information (continued) • What information is required on the on-line QPL listing? • Is a Nadcap Audit required for the qualification? • What are the requalification/recertification/ periodic testing/sampling requirements? • Will grandfathering of materials be applicable? 26 Request for Development of a QPG • Formal Letter to the QPMC • Formal Presentation at the QPMC Spring or Fall Meeting – Time for approval – Time for implementation 27 www.eAuditNet.com -On-line QPL -Program Documents 28 eAuditNet.com Register in eAuditNet eAuditNet Support - +1 724-772-8679 29 On-Line QPL Under “Resources” select, “Online QPL”. 30 www.eauditnet.com Select Specific QPG • On-Line PRI-QPL OR Select a Specific Manufacturer or SAE Standard Click “Search” 31 Download Search Data Download to an Excel Spreadsheet 32 QPL Documents in eAuditNet Click as follows: •Resources •Documents •Public Documents •QPL Programs 33 PRI eAuditNet Website Link • Link PRI On-Line QPL Search to SAE Standards Website – Button would indicate “click here to purchase the SAE specification” Link to SAE to Purchase the Standard 34 SAE Website Link • Link SAE Standards website to PRI QPL – Button would indicate “PRI-QPL” Link to eAuditNet 35 CACRC QPL Search Results 36 Questions???? 37