Topics/Research Areas - ERC/NSM

advertisement

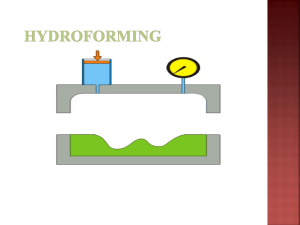

CPF Center for Precision Forming (www.cpforming.org) Taylan Altan, Director (email: altan.1@osu.edu) A short Review July, 2011 Introduction CPF • The Ohio State University (OSU) and have established the Industry/University Cooperative Research Center (I/UCRC) on Precision Forming (CPF) focusing on research needs of metal forming industry. • Funding is provided by National Science Foundation (NSF) and member companies. • CPF (www.cpforming.org) benefits from research conducted at Engineering Research Center for Net Shape Manufacturing (ERC/NSM – www.ercnsm.org). 2 Objectives CPF • Improve existing metal forming processes/products and develop new innovative processes, tooling and equipment. • Conduct projects in close collaboration with industry and transfer the results to the member companies. • Train and educate engineers in the fundamentals and practice of metal forming science and technology. 3 Current Members • Aida- America Corp. CPF • Boeing • EWI •Honda • ESI North America • General Motors Corp. • Interlaken Technology Corp. • POSCO (Korea) • IM Steel • Scientific Forming Technologies (SFTC) Corp. • IMRA America • Metalsa • JCI • Thixomat • Tyco •Labein •Cincinatti, Inc 4 Current Projects CPF CPF 1.1: Elevated temperature stamping and hydroforming of Al, Mg and Stainless Steel Objective: Develop guidelines for elevated temperature sheet forming (process optimization, lubricant evaluation and Finite Element Modeling) Warm deep drawing (in cooperation with AIDA Engineering, Ltd.) 5 Current Projects CPF CPF 1.4: Investigation of springback in forming Advanced/High Strength Steel (A/HSS) Objectives: Determine the variation of Young’s Modulus with deformation /strain Predict and reduce springback in stamping A/HSS Planned experiments (Tool concept) 1. Straight flanging 2. Stretch flanging 3. Shrink flanging 4. Straight hat shape drawing and stretching 5. Curved hat shape drawing and stretching 6 Current Projects CPF CPF- 2.1: Determination of room temperature properties of Al and steel sheet materials under biaxial conditions Objective: Develop a standardized tool design and procedure to determine flow stress, anisotropy and formability under biaxial deformation Sheet bulge test (Viscous Pressure Forming –VPF) 7 Current Projects CPF CPF- 2.2: Determination of flow stress of Al and Mg sheet materials at elevated temperatures Objective: Determine flow stress of sheet materials at elevated temperatures for the warm forming process. Hole Modified Limiting Dome Height (MLDH) Test Inverse Analysis Technique Formed sample (OD = 14in, t0 = 0.034in) 8 Current Projects CPF CPF- 2.3: Investigation of tribological conditions in forming uncoated and galvanized Advanced/Ultra High Strength Steels (A/UHSS) Objective: Determine the effect of process parameters (interface temperature, pressure and relative sliding speed) on galling / reduce galling Micrograph of galled surface Tool surface P rm A T Twist compression Test (TCT) (in cooperation with IRMCO) Galling • Testing materials: DP 600 Bare with Lub A 9 • Testing conditions: P = 170 MPa & N= 8.9 RPM CPF Current Projects CPF - 4.1: Multi Point Control (MPC) die cushion and blank holder technology in stamping Objective: Develop an automated system to optimize the Blank Holder Force for robust stamping Die Blank holder / Binder Individual hydraulic cylinders for each cushion pin Location of cushion pins/ cylinders in the die (Source: Müller Weingarten) Proposed system for robust stamping using MPC (continue) 10 Current Projects CPF CPF - 4.1: Multi Point Control (MPC) die cushion and blank holder technology in stamping (continue) Parts formed with OSU software by USCAR (try-out reduced from 3 days to 3 hours) Al 6111-t4 (t = 1 mm) BH210 (t = 0.81 mm) DP500 (t = 0.78 mm) Sample parts [GM lift gate inner panel] with different materials and sheet thickness was formed in the same die by simply adjusting the BHF. 11 Current Projects CPF CPF- 4.2: Applications of Tube Hydroforming (THF) Technologies Objective: Utilize past R&D experience at OSU to assist interested companies in introducing and/or improving the hydroforming technology A. C. B. D. General concept of Tube Hydroforming Process (Hydroforming of the T-shape part) [Leitloff , 1997 ] 12 Center for Precision Forming CPF (CP-Forming-www.cpforming.org) New tasks under consideration • Cold and Warm Hydroforming of Al and Mg alloys • Simulation of Hot Stamping of Boron Steels • Precision /Flashless Forging of automotive components (for example tie rods, pinion gears and bevel gears) • Prediction and reduction of residual stresses in machining and burnishing (advanced FE analysis) • Micro-stamping for electronic applications (lead frames, CD drive components, etc.) 13