Productivity

advertisement

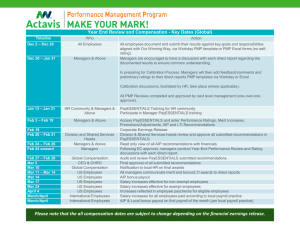

Canada-Denmark “Productivity” Seminar Productivity on the shop floor/social organization of work Protected by Danfoss copyright Ejner Kobberø: Market Support Manager Danfoss A/S Automatic Controls Operations Nordborg Key Figures Financial Factory turnover 552 M DKK (96 M USD) Output Units/year 6.400.000 pcs Employees Blue collars 280 White collars 55 Production 11.200 m2 Administration 1.600 m2 Space Certificates ISO 9001, ISO 14001, OHSAS 18001 Systems TQM Standardized mgmt system ERP SAP R3 SPC Q – das Maintenance DVS PMS Online system Protected by Danfoss copyright 1 10 principles for all production factories in the Danfoss Group Danfoss Productivity Program This presentation is protected by Danfoss copyright and solely for the use of Danfoss personnel. No part of it may be circulated, quoted, or reproduced for distribution outside the Danfoss organization without prior written approval from Danfoss Business System. This material was used by Danfoss Productivity Program during an oral presentation; it is not a complete record of the discussion. Protected by Danfoss copyright 10 principles for all production factories in the Danfoss Group Our production culture will be characterised by: 1 Creating value – all activities must create value for our customers 2 Production according to customer orders – we base all production on the actual needs of customers, optimised production flow and a minimum of stock (in short: pull not push) 3 Production teams – we group production employees into teams, each with a team coordinator who will facilitate an optimal production flow 4 Standard Operating Procedures (SOPs) – we standardise all processes and document them in SOPs 5 Continuous improvements – we make continuous improvements by constantly optimising our way of working, systematically solving problems and building competences 6 Hourly follow-up on production – we detect deviations from planned production immediately and respond with corrective actions 7 Stretched targets – we always set stretched targets for improvement activities that are based on: ”What if everything goes right?” 8 Follow-up on improvement activities – we ensure a maximum impact on the bottom line by calculating the improvements in total costs and following up via KPIs (Key Performance Indicators) 9 Committed management – our leaders are visible and active in the production area and are ambassadors for the Danfoss Productivity Program 10 Respect for people – we involve and support our employees in the change process, in accordance with Danfoss’ values Protected by Danfoss copyright 3 Creating value – all activities must create value for our customers 1 We create value by removing waste: 8. Untapped human potential 1. Overproduction 2. Waiting 3. Transport 7. Motion 4. Over-processing 5. Inventory 6. Scrap & Rework 4 Production according to customer orders – we base all production on the actual needs of customers, optimised production flow and a minimum of stock (in short: pull not push) Material and Information Flow Analysis Pull system • Suppliers Weekly Demand: Customers ORDERS Daily weekly monthl y Company weekly confir med orders Weekl y Deman d: MRP system 500 pallets Raw materials 22500 28500 Saw & Debur r 600 Weld & Decarb Available time Available time manual cycle time 13500 Rotaje t Available time manual cycle time 10000 Paint Available time manual cycle time machine cycle time machine cycle time machine cycle time machine reliability machine reliability machine reliability changeover time changeover time shared / dedicated shared / dedicated 100 changeover time changeover time shared / dedicated shared / dedicated ‘G’ Build, Test & Final Assy 2000 A 1000 B 4000 C 3000 Finished Goods Benefits: • Prevents overproduction • Controls inventory • Makes production system visual • Drives improvement • Synchronises processes with customer rhythm Despa tch Available time Available time manual cycle time machine cycle time machine reliability 2 manual cycle time manual cycle time machine cycle time machine cycle time machine reliability machine reliability changeover time changeover time shared / dedicated shared / dedic ated 26000 Schau For longest component stream blin Available time manual cycle time machine cycle time machine reliability changeover time shared / dedicated Processing time Manufacturing Lead time = Processing Lead time 120s 28.5 d 250s 22.5 d 180s 0.6 d 1540s 77.8 d 240s 13.5 d = 0.06% 250s 10 d 500s 2d Push system • Use Material and Information Flow Analysis as a tool to diagnose lack of flow and design improved flow Bad symptoms: • Production in advance and delayed production at the same time • High level of WIP Ensure optimization across the value stream instead of local optimization Protected by Danfoss copyright 5 Production teams – we group production employees into teams, each with a team coordinator who will facilitate an optimal production flow 3 Supports organization around flows with team coordinators Ensure respect of and adherence to standards Allocate clear authority to change the standards Establish necessary foundation for reaching targets Simplify management by alignment around common targets Establish motivational environment Basis for capability building programmes Protected by Danfoss copyright 6 Standard Operating Procedures (SOPs) – we standardise all processes and document them in SOPs 4 Protected by Danfoss copyright Eliminates uncertainty in the process Establishes a natural contract between management and shop floor Provides the right baseline to establish targets Provides degrees of freedom for shop floor to identify improvements 7 Continuous improvements – we make continuous improvements by constantly optimising our way of working, systematically solving problems and building competence 5 Proposals to problem tasks are made by the production team Continuous reaction and corrections (just do it) by the production team according to planned production 1 2 3 Problem tasks are prioritized and solved Reasons to problems are removed and the team performance is improved 4 Systematic capture of problems and suggestions from employees Continuous use of Root Cause Problem Solving to improve all processes 6. Standardize/ formalize solution 1. Identify problem 5. Evaluate solution The 6 Step Method Eliminate the 8 waste System and Method 2. Analyze problem 4. Implement solution 3. Find cause and solution Organisation Protected by Danfoss copyright Attitudes and Competences 8 Hourly follow-up on production – we detect deviations from planned production immediately and respond with corrective actions Område: Dato: Skift: Plan Tid: Emne nr. Ansvarlig: Aktuelt Akk. Plan Bemanding Akk. aktueltDifference 14:15 - 15:15 027G5670 12 12 13 13 0 15:15 - 16:15 148B7070 10 22 9 22 0 16:15 - 17:15 148B7070 8 30 7 29 -1 17:15 - 18:15 148B7070 10 40 18:15 - 19:15 168B9570 5 50 19:15 - 20:15 168B9570 10 60 20:15 - 21:15 168B9570 10 70 21:15 - 22:15 168B9570 10 80 Plan Aktuelt Kommentarer Creates transparency for early identifying of abnormalities from standards and deviations from targets Changes problem solving modus from reactive to proactive Performance BD-K Produktion Mål 1,2 14 hours prod.time 10 hours pred. time 1 %af planlagt (90% OEE) 6 Provides foundation for root cause elimination Allows managers at all levels to justify development of operations 0,8 0,6 0,4 Defect marker Ready on Monday morning ;) 0 03. jan. 04. jan. 05. jan. 06. jan. 07. jan. 10. jan. 11. jan. 12. jan. 13. jan. 14. jan. 17. jan. 18. jan. 19. jan. 20. jan. 21. jan. 24. Jan. 25. Jan. 26. Jan. 27. Jan. 28. Jan. 31. Jan. 1. feb. 2. feb. 3. feb. 4. feb. 7. feb. 8. feb. 9. feb. 10. feb. 11. feb. 14. feb. 15. feb. 16. feb. 17. feb. 18. feb. 21. feb. 22. feb. 23. feb. 24. feb. 25. feb. 28. feb. 1. mar. 2. mar. 3. mar. 4. mar. 7. mar. 8. mar. 9. mar. 10. mar. 11. mar. 14. mar. 15. mar. 0,2 Dato Protected by Danfoss copyright 9 Stretched targets – we always set stretched targets for improvement activities that are based on: ”What if everything goes right?” Limit analysis approach Based on a future state (stretched Performance targets) - constantly set short term activity plans and targets to drive continuous Improvement Limit What if it all goes right? Target Gap Current 7 Gain Future states to be challenged and reviewed as a standard process Provides the guidelines for prioritization What can I achieve ? •Global vision •Extended scope of progress •Good perception of deviations from benchmark Time of work Ensures focus and momentum of entire organization Supports motivation Structural performance gain Protected by Danfoss copyright 10 Follow-up on improvement activities – we ensure a maximum impact on the bottom line by calculating the improvements in total costs and following up via KPIs (Key Performance Indicators) Define the priorities of actions relevant for the plant or the value stream and the corresponding Key Performance Indicators (KPIs) 8 Set the targets and the associated action plans to achieve those argets Priorities and KPIs definition Targets setting and actions plan Creates linkage to performance management system Monitoring Countermeasures Implement the monitoring process of operations at all levels of the plant organization Ensure a rigorous reactivity process to develop effective counter-measures in case of deviations Ensures commitment Capitalizes realized efforts Relates impact to present value Ensures long-term perspective Activities prioritised against business case and impact Total cost of all activities who support Mål Produktivitet Realisedt 2004: 17,3 FV. per manhour. 25 Mål: Efter DPP rationaliseringer. 20 operations 15 10 5 0 52 1 Protected by Danfoss copyright 2 3 4 5 6 7 8 9 10 11 11 Committed management – our leaders are visible and active in production and are ambassadors for the Danfoss Productivity Program “I will change my behaviour if…” “The systems reinforce the future state” 9 Role modelling through “Management By Walking Around” Capability building Aligned systems & structures “I have the skills to behave in the new way” Visual checks of activities, plans and countermeasures Management as mentors to build the train-the-trainer organisation Standardised reviews of targets with focus on countermeasures not excuses Role model slide “I see my leaders behaving differently” Role modelling Understanding & commitment Ensure sense of urgency to always improve Demands quick response from “I know what I need to change and want to do it” management ” If you’re looking for perfection, look in the mirror. If you find it there, expect it elsewhere”. Malcolm Forbes Protected by Danfoss copyright 12 Respect for people – we involve and support our employees in the change process, in accordance with Danfoss’ values A satisfied and smooth organization A new and positive level 5 Point of satisfaction The new point of satisfaction 1 Hill of renewal Hill of disowns Threats coming from changes in the environment 4 2 Wood of confusion and frustration 3 Danfoss Core values 10 Our business is trust A very safe and reliable choice Acknowledgement of difficulty Support change by ensuring relevant communications, training and rewards Support to help people understand their new roles Support through role modelling Change management abilities in all managers Change in accordance with Danfoss´ values Passionate about technology Global culture, local representation Environmentally and socially responsible Protected by Danfoss copyright 13 Schematic flow overview – Small TXV TU - preassembly TR / TUC CDC Final assy CDC TR Preassy TR Solder Laser Washing T2 Solder Protected by Danfoss copyright T2 – T2 / TUA/TUB/TC Preassy Final assy Packing CDC 14 Performance management in AC-BN KPI’s Performance cockpit Weekly report Follow up meetings (shift, day, week, month, ½ year) Protected by Danfoss copyright 15