Cost Calculation

advertisement

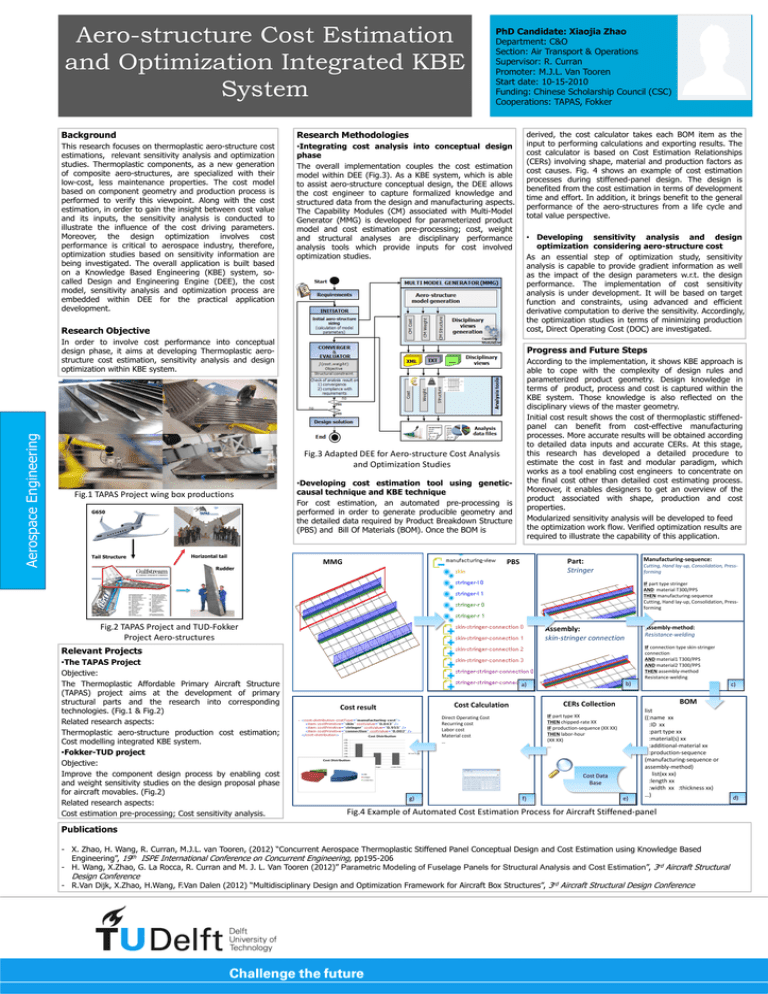

Aero-structure Cost Estimation and Optimization Integrated KBE System PhD Candidate: Xiaojia Zhao Department: C&O Section: Air Transport & Operations Supervisor: R. Curran Promoter: M.J.L. Van Tooren Start date: 10-15-2010 Funding: Chinese Scholarship Council (CSC) Cooperations: TAPAS, Fokker Background Research Methodologies This research focuses on thermoplastic aero-structure cost estimations, relevant sensitivity analysis and optimization studies. Thermoplastic components, as a new generation of composite aero-structures, are specialized with their low-cost, less maintenance properties. The cost model based on component geometry and production process is performed to verify this viewpoint. Along with the cost estimation, in order to gain the insight between cost value and its inputs, the sensitivity analysis is conducted to illustrate the influence of the cost driving parameters. Moreover, the design optimization involves cost performance is critical to aerospace industry, therefore, optimization studies based on sensitivity information are being investigated. The overall application is built based on a Knowledge Based Engineering (KBE) system, socalled Design and Engineering Engine (DEE), the cost model, sensitivity analysis and optimization process are embedded within DEE for the practical application development. •Integrating cost analysis into conceptual design phase The overall implementation couples the cost estimation model within DEE (Fig.3). As a KBE system, which is able to assist aero-structure conceptual design, the DEE allows the cost engineer to capture formalized knowledge and structured data from the design and manufacturing aspects. The Capability Modules (CM) associated with Multi-Model Generator (MMG) is developed for parameterized product model and cost estimation pre-processing; cost, weight and structural analyses are disciplinary performance analysis tools which provide inputs for cost involved optimization studies. derived, the cost calculator takes each BOM item as the input to performing calculations and exporting results. The cost calculator is based on Cost Estimation Relationships (CERs) involving shape, material and production factors as cost causes. Fig. 4 shows an example of cost estimation processes during stiffened-panel design. The design is benefited from the cost estimation in terms of development time and effort. In addition, it brings benefit to the general performance of the aero-structures from a life cycle and total value perspective. • Developing sensitivity analysis and design optimization considering aero-structure cost As an essential step of optimization study, sensitivity analysis is capable to provide gradient information as well as the impact of the design parameters w.r.t. the design performance. The implementation of cost sensitivity analysis is under development. It will be based on target function and constraints, using advanced and efficient derivative computation to derive the sensitivity. Accordingly, the optimization studies in terms of minimizing production cost, Direct Operating Cost (DOC) are investigated. Research Objective Aerospace Engineering In order to involve cost performance into conceptual design phase, it aims at developing Thermoplastic aerostructure cost estimation, sensitivity analysis and design optimization within KBE system. Progress and Future Steps According to the implementation, it shows KBE approach is able to cope with the complexity of design rules and parameterized product geometry. Design knowledge in terms of product, process and cost is captured within the KBE system. Those knowledge is also reflected on the disciplinary views of the master geometry. Initial cost result shows the cost of thermoplastic stiffenedpanel can benefit from cost-effective manufacturing processes. More accurate results will be obtained according to detailed data inputs and accurate CERs. At this stage, this research has developed a detailed procedure to estimate the cost in fast and modular paradigm, which works as a tool enabling cost engineers to concentrate on the final cost other than detailed cost estimating process. Moreover, it enables designers to get an overview of the product associated with shape, production and cost properties. Modularized sensitivity analysis will be developed to feed the optimization work flow. Verified optimization results are required to illustrate the capability of this application. Fig.3 Adapted DEE for Aero-structure Cost Analysis and Optimization Studies Fig.1 TAPAS Project wing box productions G650 Tail Structure Horizontal tail Rudder •Developing cost estimation tool using geneticcausal technique and KBE technique For cost estimation, an automated pre-processing is performed in order to generate producible geometry and the detailed data required by Product Breakdown Structure (PBS) and Bill Of Materials (BOM). Once the BOM is MMG Manufacturing-sequence: Part: Stringer PBS Cutting, Hand lay-up, Consolidation, Pressforming IF part type stringer AND material T300/PPS THEN manufacturing-sequence Cutting, Hand lay-up, Consolidation, Pressforming Fig.2 TAPAS Project and TUD-Fokker Project Aero-structures Assembly-method: Resistance-welding Assembly: skin-stringer connection IF connection type skin-stringer connection AND material1 T300/PPS AND material2 T300/PPS THEN assembly-method Resistance-welding Relevant Projects •The TAPAS Project Objective: The Thermoplastic Affordable Primary Aircraft Structure (TAPAS) project aims at the development of primary structural parts and the research into corresponding technologies. (Fig.1 & Fig.2) Related research aspects: Thermoplastic aero-structure production cost estimation; Cost modelling integrated KBE system. •Fokker-TUD project Objective: Improve the component design process by enabling cost and weight sensitivity studies on the design proposal phase for aircraft movables. (Fig.2) Related research aspects: Cost estimation pre-processing; Cost sensitivity analysis. b) a) BOM CERs Collection Cost Calculation Cost result IF part type XX THEN chipped-rate XX IF production-sequence (XX XX) THEN labor-hour (XX XX) … Direct Operating Cost Recurring cost Labor cost Material cost … Cost Data Base g) f) c) e) list ((:name xx :ID xx :part type xx :material(s) xx :additional-material xx :production-sequence (manufacturing-sequence or assembly-method) list(xx xx) :length xx :width xx :thickness xx) …) Fig.4 Example of Automated Cost Estimation Process for Aircraft Stiffened-panel Publications - X. Zhao, H. Wang, R. Curran, M.J.L. van Tooren, (2012) “Concurrent Aerospace Thermoplastic Stiffened Panel Conceptual Design and Cost Estimation using Knowledge Based Engineering”, 19th ISPE International Conference on Concurrent Engineering, pp195-206 - H. Wang, X.Zhao, G. La Rocca, R. Curran and M. J. L. Van Tooren (2012)” Parametric Modeling of Fuselage Panels for Structural Analysis and Cost Estimation”, 3rd Aircraft Structural Design Conference - R.Van Dijk, X.Zhao, H.Wang, F.Van Dalen (2012) “Multidisciplinary Design and Optimization Framework for Aircraft Box Structures”, 3rd Aircraft Structural Design Conference d)