NE 110 – Introduction to NDT & QA/QC Overview of QA/QC

advertisement

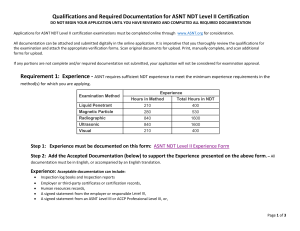

NE 110 – Introduction to NDT & QA/QC Overview of QA/QC; NDT & QA/QC Certification Requirements Prepared by: Chattanooga State Community College Definitions • Quality Assurance: “All the planned and systematic activities implemented within the quality system, and demonstrated as needed, to provide adequate confidence that an entity will fulfill requirements for quality.” • Quality Control: “Operational techniques and activities that are used to fulfill requirements for quality.” Comparison of QA and QC • QA - a program set up by management to develop procedures to follow to ensure that standards of quality are being met • QC – involves the actual testing of products to uncover defects or to ensure a product meets design specifications Key QA/QC Concepts • Quality auditing – independent review • Metrology – “science of measurement” • Root cause analysis – identification of the original reason for process nonconformance • Preventive/corrective actions – change enacted to eliminate nonconformance • Continual improvement – on-going effort to improve a process QA/QC Concentrations • Civil – Soil testing, inspection of structural steel or concrete 1st inspectors needed to support new construction • Mechanical – Inspection of valves, pumps, piping systems, hangers/supports, lubrication systems, etc. QA/QC Concentrations Continued • Electrical/I & C – Need basic understanding of electrical equipment such as batteries, breakers, transformers, relays, motors, grounding systems, etc. – Inspection of raceways, cable trays, wire terminations • Receipt of equipment All QC personnel must be trained in methods of documentation, reporting, and records management American Society for Quality (ASQ) • Offers 17 quality certifications • Web-site provides description and education/experience requirements for: – – – – – CQI (Certified Quality Inspector) CQE (Certified Quality Engineer) CQA (Certified Quality Auditor) CQT (Certified Quality Technician) CQM/OE (Certified Manager of Quality/Organizational Excellence) Certified Quality Inspector • Description: – – – – performs laboratory procedures inspects products measures process performance records data/prepares formal reports • Requires two years OJT (with high school diploma or GED) • Exam topics include: – – – – Mathematics (20%) Metrology (30%) Inspection and test (30%) Quality assurance (20%) International Organization for Standardization (ISO) • International standard-setting body composed of representatives from various national standards organizations • Founded in 1947 • Headquartered in Geneva, Switzerland International Organization for Standardization (ISO) • ISO derived from the Greek word isos, meaning “equal” (pronounced the same in all languages) • Members from 163 countries • ANSI is the US-representative to ISO • ISO standards voluntary agreements based on consensus of international expert opinion ISO Quality Management Standards • Provide a model to follow in setting up and operating a management system ISO 9000 Family • An international consensus on good quality management practices • ISO 9001:2008 – a set of standardized requirements for a quality management system against which organizations can be certified • Outlines requirements for: – – – – Control of documents/records Internal audits Control of nonconforming product/service Corrective action/preventive action • ISO 9712 – NDT Qualification and Certification of Personnel ISO 9001 Criticisms • Amount of money, time, and paperwork required for registration • Certification does not guarantee products produced are any good (as long as manufacturing consistent and welldocumented) ANSI • Founded in 1918 to enhance global competitiveness of U.S. businesses and U.S. quality of life by promoting and facilitating voluntary consensus standards • Accredits procedures of standards-developing organizations • More than 10,000 ANSI standards in publication ANSI History ANSI Standards • ANSI N45.2 series – QA program standards for design and construction of nuclear power plants • ANSI N45.2.6 – Delineates the qualification requirements for persons who perform inspections, examinations, and test to determine conformance of safety-related items to specific criteria – Excludes NDT (covered by SNT-TC-1A) – Not applicable for purposes other than verifying conformance – Not applicable to personnel who perform technical specification surveillance testing ANSI 45.2.6 Qualification for Inspectors • Levels I, II, and III (III is highest level) • Requires formal training, OJT, and the satisfactory completion of a written exam – TVA’s NQAP (Nuclear Quality Assurance Program) provides alternate qualification requirements Level I/II Functions • Level I technicians responsible for: – Recording of test data – Implementation of test procedures • Level II technicians also responsible for: – – – – – Planning inspections, including test set-up Evaluating validity and acceptability of test results Reporting of test results Supervision of lower level personnel Qualification of lower level personnel Level III Functions • Level III technicians also responsible for: – Evaluating the adequacy of programs to train and test inspection personnel – Qualification of same level personnel ASNT • American Society for Nondestructive Testing • “ASNT exists to create a safer world by promoting the profession and technologies of nondestructive testing” • Key Certification Standards: – SNT-TC-1A, “Personnel Qualification and Certification in Nondestructive Testing” – ANSI/ASNT CP-189, “ASNT Standard for Qualification and Certification of Nondestructive Testing Personnel” NDT Certification • Standards detail minimum training, education, and experience requirements • Require employers to establish a procedure for certification of NDT personnel (called a “written practice”) • Qualification vs. Certification • 6 Levels of Qualification (CP-189): Trainee, Level I, Level II Limited, Level II, Level III, NDT Instructor NDT Certification Requirements • Level I or II certification usually provided by employer • For certification, individuals must pass: – General written exam – Specific written exam addressing equipment, procedures, techniques, codes, etc. for the organization – Practical exam (demonstration of test and recording of results) • Level III certification requirements may require testing by ASNT or ASME ATA • Air Transportation Association, a trade organization for U.S. airlines • Founded in 1936 • Two ATA documents serve as guidelines for the training of inspection personnel – ATA Specification 105, Guidelines for Training and Qualifying Personnel in Non-Destructive Testing Methods – ATA Specification 107, Visual Inspection Personnel Training and Qualification Guide for FAR Part 121 Air Carriers AIA • Aerospace Industries Association, represents major manufacturers of commercial, military, and business aircraft and spacecraft • Established in 1919 • NAS 410, Certification & Qualification Of Nondestructive Test Personnel – replaces MILSTD-410E (military test standard) • NAS 999, Nondestructive Inspection of Advanced Composite Structure