How will the values of NMP affect the SL organisation

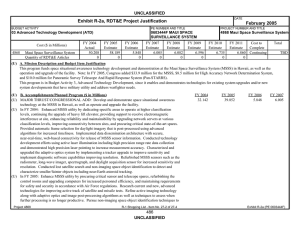

advertisement

Magnox Swarf Storage Silos Programme Decommissioning Delivery Partnership Requirements February 2014 Gavin Askew MSSS Programme Context • The MSSS Programme manages and mitigates the significant radiological and environmental hazard presented by the inventory held within the facility. • Facility constructed in four phases from the 1960s to 1980s • One of the highest priorities for decommissioning in the NDA portfolio • NDA and Stakeholder challenge to accelerate risk and hazard reduction • Age and proximity to other buildings limits the scope for structural improvements • Currently a suite of major capital, retrievals and facility resilience projects are in progress and in various stages of maturity. MSSS Programme Context Programme Status The MSSS Programme is being delivered in 7 tranches, resulting in successive risk reduction and the removal of the hazard posed by the waste currently stored in the MSSS facility. MSSS Programme Tranches MSSS Programme Benefits 1 – Pre retrievals risk reduction structured as a programme 1 – Safer, More Efficient Control & Delivery of Work 2 – Risk & Consequence from Hydrogen Event Reduced & Facility More Resilient 3 – Reduced Risk from a Seismic Event & Facility More Resilient 2 – MBGW removal capability 4 – Site Hazard & Risk Reduced Due to MSSS Beta Gamma Waste Removal 3 – Sludge bearing waste removal capability 5 – Site Hazard & Risk Reduced Due to MSSS Bulk Waste Removed 4 – MSSS stream full operational capability 5 – MSSS residuals removal capability 6 – MSSS facility POCO & decommissioning capability 6 – Site Hazard & Risk Reduced Due to MSSS Residuals Removed 7 – End state 7 – Site Hazard & Risk Reduced Due to MSSS Facility Removed The duration of the DDP covers activities relating to the first 4 of these tranches, thus requiring a wide range of capabilities and interfaces with SL and supply chain organisations. Key Delivery Challenges for MSSS • Complex Environment • Significant ramp up in plant based activity over next 5 years • Transition from a Nuclear Asset Management and Capital Projects environment into a Nuclear Waste Operating and Decommissioning Retrievals environment. • The required degree of programme and project level technical and planning integration • Uncertainty in the waste form • Limited Material Import and Export Routes • Availability of sufficient skilled Resources Capability required from DDP Skills Service/Capability Requirements Facility Integrator •Coordination and delivery of physical activities within the facility. •Development of existing Integrated Work Management capability. •Facility Logistics Strategic Programming support •Support development of Programme Management and Programme Baseline maturity. •Ongoing assurance of adherence to the Programme Execution Plan. Delivery Agent •Accelerated project execution covering detail design, fabrication, construction and setting to work •Material, component and plant procurement •Commissioning and Start-up: Nuclear safety commissioning preparation, Inactive nuclear safety commissioning and Active nuclear safety commissioning. Programme controls •Integrated Programme planning, monitoring and control Commercial and Procurement Management capability •Augmentation of existing Commercial and Procurement Management capability Programme Supply Chain Arrangements Key Requirements We are looking for : • Collaborative behaviours • Ability to integrate with existing organisation • Ability to accommodate and react to evolving requirements • Ability to reduce the time and costs associated with high degrees of contestation within the facility • Provision of access to SQEP resources and competent T3/T4 delivery organisations • Active management of bottlenecks • Innovation • A risk sharing approach Disclaimer Important Information • This communication and its contents have been provided to you for informational purposes only. This communication is not advice on or a recommendation of any kind with respect to the matters described herein, including without limitation, contracting structures, contracting instruments, contracting strategies, related legal and commercial issues or any combination of such matters. This communication does not offer advice. • No information contained herein constitutes an offer or solicitation by or on behalf of Sellafield Ltd to enter into any contractual arrangement. Sellafield Ltd. makes no representations or warranties, express or implied, regarding the accuracy, adequacy, reasonableness or completeness of the information, assumptions or analysis contained herein or in any supplemental materials, and Sellafield Ltd. accepts no responsibility or liability in connection therewith. Opinions expressed in this presentation are subject to change without notice.