OCCCs Strategic Planning Approach cuts costs

advertisement

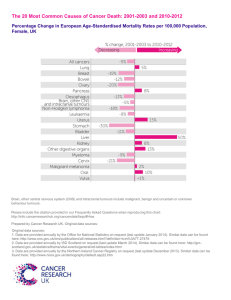

Oklahoma City Community College Strategic Planning Approach Cuts Cost….Improves the Learning Environment Smart and Sustainable Campuses Conference Monday, April 15, 2013 Presenters • J. B. Messer, Director of Facilities Management, Oklahoma City Community College (OCCC) • Mike Presson, Area Manager, Trane 2 Learning Objectives • Learn how a rapidly growing school combined a significant expansion with more energy efficient, costsaving infrastructure systems • Gain tips and guidance for assessing current infrastructure systems and evaluating potential improvements on your own campus • Understand the importance of collaboration in creating energy savings • Walk away prepared to apply similar methodologies to your school based on factors such as educational, environmental and budgetary objectives 3 Campus Transformation 1999-2012 • • • • Campus footprint increased 43.1% (‘99-’09) Electricity cost has increased 40.1% (‘99-’09) Electricity consumption has increased 6.2% (‘99-’09) Consumption cost per square foot has decreased 25.8% (‘99-’09) • Added an additional 180,000 square feet in the past (3) years (‘09-’12) with no increase in utility budgeting 4 Growth in Square Footage 5 Electricity Cost Per Kilowatt 6 Growth in Energy Consumption 7 Annual Kilowatt per Square Foot 1999 - OCCC used 26.73 kilowatt (kwh)/sq. ft. annually 2009 - OCCC used 19.83 KWH/sq. ft. annually This equates to a decrease of 25.8% in energy consumption campus-wide At the current electric utility rates, OCCC is saving $127,095 annually 8 How Does OCCC Compare? Energy total cost per GSF comparisons: • National $2.25 • Regional $2.25 • OCCC $2.12 Additional $125,000 annually in cost avoidance Based on per Student FTE utility expenditures (representative of facilities loading) • National $663.95 • Regional $588.14 • OCCC $212.45 Additional $3.2M – $5.6M annually in cost avoidance 9 Underground Condenser Water Storage • Underground condenser water storage system provides cooler water conditions 10 Ice Bank System • Ice bank storage system allows for power peak shaving 11 Free-Cooling Heat Exchange • Free-cooling heat exchanger provides campus-wide cooling up to approximately 50 degrees outside air temperature 12 Re-engineered Central Plant • Re-engineered central plant to provide for a primarysecondary variable flow system. Reduced system pumping power by 80%, and expanded system capacity for future campus growth. 13 Advantages of Low Load Boilers • Low load boilers eliminate the need for the larger natural gas consuming boiler systems for two months of the heating season 14 Three-Way Valve to Two-Way Valve Conversions • Provided finer control of the chilled water and heating water flow to the air handling units. Also reduced total system flow, thus increasing the flow capacity of the main central plant. 15 Centrifugal Chiller Replacements • Chilled water system replacement - Estimated energy savings of $40,000 annually. 16 Standardized Management System Standardized Campus-wide Energy Management System • The campus is currently 98% totally automated on all energy consuming systems • OCCC installs all of its control systems at a savings of $30,000 annually • The energy management system provides time-ofday and usage scheduling, optimizing space usage, troubleshooting, and monitoring at a single remote location • Has allowed for the reduction in manpower needs (two FTE positions) saving an additional $100,000 annually 17 The Present Future • Strategic three-year plan (in progress…update annually) • High-efficiency equipment upgrades (in progress as opportunities arise) • Replace T-12 magnetic ballast lighting systems with high efficiency T-8 or T-5 systems (in progress) 18 The Present Future - Continued • Identify existing systems where alterations can be made to improve total system operating efficiencies (add to functional five-year plans) • Perform facilities studies utilizing “green” standards to identify future system improvements (develop into new construction and renovations) • Oklahoma Senate Bill 1096 (signed by the Governor in May 2012) 19 Strategic Planning Process • Faculty and staff annual surveys • SWOT analysis with facilities management personnel • Development of specific, measurable, attainable, realistic and timeline (SMART) goals and objectives • Annual review of the Facilities Management Strategic Plan • Development of five-year plans to address all functional components 20 Strategic Opportunities • New construction • Renovations • System upgrades • Training and research • Working with Trane Commercial and other strategic business partners to meet goals and objectives 21 The Trane Brand is about Building Life Our careful attention to the needs of the building can improve the life of equipment, controls and systems. Meeting the needs of the building promotes environments that impact the lives within the building and fosters productivity and profitability. 22 What We Deliver Performance Innovation Commitment Knowledge Customers experience efficiency, effectiveness and reliability 24/7 Trane brings new ideas, problem solving and an inquisitive look and guidance to impact energy efficiency and sustainability Customers can trust Trane to deliver loyalty, passion and dedication to their mission The Trane legacy of excellence delivers knowledge and the true expertise customers trust We deliver innovation, driven by performance, undeniable commitment, and unprecedented knowledge that is unmatched in the industry. 23 Leading the industry in Sustainability • We are industry leaders in working with energy advocates to create • • • • new energy saving standards for HVAC products and systems We have committed to reduce energy use 25% by 2019 across all our facilities and were recently recognized by the US EPA for the aggressiveness of our goals when compared to our peers We are innovating to identify the most environmentally conscious way to bring comfort to the built space through consideration of full life cycle product environmental impacts Trane received an industry-first Environmental Product Declaration for performing a life cycle assessment on a large-scale chiller We bring customers solutions that help them meet their unique energy and environmental performance goals through our high performance buildings approach based on guidance from U.S. national labs and the federal government 24 Total Lifecycle Solutions • Trane offers support for every stage of the HVAC systems’ lifecycle to meet energy use, maintenance and service concerns to achieve a High Performance Building outcome Planning & Concept Design Modernize High Performance Building Install Renovate The Trane approach to creating a high performance building outcome considers the whole building throughout its lifecycle. 25