Agricultural Engineering

advertisement

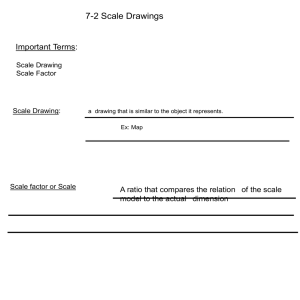

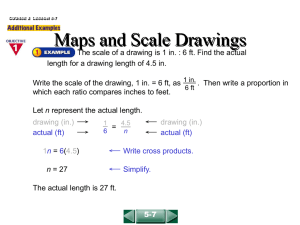

Agricultural Engineering Agriscience Applications By: Johnny M. Jessup FFA Advisor/Agriculture Teacher Safety Awareness Safety is being prepared since almost 50% of all farm related accidents involve working with machinery & equipment. Safety is developing an environment free from danger, risk, or injury. Safety Awareness The #1 key to shop safety is the people who use the shop. Workers should always…. Be trained in proper tool operations. Pass a safety test before using the shop. Principles for Safety Keep the shop in an orderly manner to prevent tripping and related injuries. Remove unnecessary hazards such as oily rags. Minimize danger by making certain all machines have safety shields to place prior to an during operation. Principles for Safety Wear appropriate protective clothing & devices. Safety glasses & goggles prevent eye injury from dust and flying objects. Leather steel-toed shoes offer protection should items be dropped or fall on the feet. Ear plugs or ear muffs can prevent hearing loss when the noise level exceeds 90 dB (decibels). Safety Color Coding National organizations worked together. Code was published by the…. American Society of Agricultural Engineers Safety Committee of the American Vocational Association Color coding alerts people to dangers & hazards, provides information to help one react quickly in an emergency. Basic Colors Red Identifies areas of danger. Used on safety switches & fire extinguishers. Danger Basic Colors Orange Identifies Warning wheels, levers, and knobs. Basic Colors Yellow Identifies that wheels, levels, and knobs that adjust or control machines. Caution Basic Colors Blue Used on signs such as “Out of order” to identify broken shop equipment that does not work properly. Information Basic Colors Green Indicates the presence of first aid and safety equipment. Safety Fire Hazards in the Agricultural Mechanics Shop The Fire Triangle Fuel Any combustible material that will burn Examples: Oily rags Saw dust Paper The Fire Triangle Heat Most materials will burn if they are made hot enough. The Fire Triangle Oxygen Gas in the atmosphere that is not a fuel, but must be present for fuels to burn. The Fire Triangle Fire Prevention Take away one of the components of the fuel triangle and fire will not start or will stop if it has started. Safe storage of fuels is the easiest fire prevention technique. Clean shop facilities also decrease the chance of fire. Fire Extinguishers Know the kind of fire extinguisher that is used for different kinds of fires prior to the fire. Class A is used for ordinary combustibles. Class B is used for flammable liquids. Class C is used for electrical equipment. Class D is used for combustible metals. A B C D Fire Extinguishers Know the placement of fire extinguishers so that time is not taken looking for them if a fire occurs. Should be hung on walls within easy reach in areas where fires would most likely occur. Using Fire Extinguishers Know how to use the fire extinguisher. Hold upright, pull the ring pin, press the lever. The nozzle of the extinguisher is directed toward the base of the fire to discharge the extinguisher. Smothering a Fire Best used on a person whose clothes are on fire. Wrap the person in a blanket to cut the oxygen off to the fire. Planning Agricultural Engineering Projects Instruments for Simple Designs Sharp Lead Pencil Needed for the highest quality scale drawing. Protractor Used for drawing & measuring angles. Good Eraser Helps makes corrections without distorting the image. 12 inch Ruler Works for basic drawing. Compass Used for drawing circles & arches. Instruments for Detailed Designs Drawing Used Board for attaching the drawing paper. Masking Tape Used to secure the drawing paper to the drawing board. T-Square Helpful for drawing horizontal lines. Instruments for Detailed Designs Right Triangle 30o x 60o x 40o Used to draw vertical lines. Scale Instrument with all increments shortened according to proportion. Two Types Flat Scale – looks similar to a ruler. Triangular scales – three sides, but six scales. Basics of Drawing Sketch Rough drawing that is not to scale. Sketches do not have dimensions included. Pictorial Shows Drawing all three sides dimensions at once. All three views (front, side (end), and top are in view. A Pictorial Drawing A. Top view B. Side or End view C. Front view Basics of Drawing Scale drawing Represents an object in exact proportion. Object is larger/smaller than the drawing itself. Examples: ¼” = 1’ Then ¼” on the drawing would equal 1’ on the actual object. 2” line on the drawing would equal 8’ on the object. (2 divided by ¼ = 8) The scale will vary depending on the size of the object being drawn. Determining Materials Bill of Materials Complete list and description of all materials needed to construct a project. Abbreviations are often used. BF= Board foot LF= Linear foot Determining Board Feet Determining board feet for small pieces. BF = Thickness (inches) x width (inches) x length (inches) 144 Determining board feet for large pieces. BF = Thickness (inches) x width (inches) x length (feet) 12 Determining Board Feet How many board feet are in a board 4” x 6” x 24”? BF = 4” x 6” x 24” 144 = 576” 144 = 1 BF How many board feet are in a board 1” x 12” x 8’? BF = 1” x 12” x 8’ 12 = 96 12 = 8 BF Basic Construction Projects Tips Wood Projects Fastest way to fasten wood is by nailing. Nail hammer or nail gun are preferred tools for driving nails. Screws hold better than nails and are driven quickly with power screwdrivers. Flathead screw is the one most used in woodworking. Wood Projects Bolts are particularly useful for fastening wood at high stress points. Gluing is the strongest method of fastening wood. Often used along with nails, screws, etc. Boards are held in place for gluing by clamps. Dowel pins are round wood pins sometimes used to strengthen wood joints. Metal Projects Steel Most commonly used metal in agricultural mechanics. Marking Steel Presents a special problem as pencil marks do not show up well. Soapstone Soft, gray rock. Cut into thin pieces resembling pencils. Shows up well on most metals. Cutting Metal Hack Saw Hand tool most often used for cutting metal. Especially useful for cutting thin conduit. Metal Cutting Band Saw & Power Hacksaws May be used for large projects. Careers Careers Attracts students interested in operation, maintenance, service, and selling of agricultural equipment. Varied careers in Production support such as Tractor mechanic, farm machinery assembler, Agriculture Safety Engineer. Careers Careers also in horticulture such as irrigation engineer, Lawn mower mechanic, Agriculture Equipment designer. Education varies with the type of Agriscience mechanics career chosen and working conditions. Broad field includes agricultural processing. Careers Electricians design & wire agricultural equipment structures. Careers Use of engineering equipment like levels & tripods to survey, layoff, and construct terraces. Use of earth moving machinery to control erosion. Careers Diesel mechanics are in demand because….. Of the large amounts of diesel powered equipment. Builders of structures & equipment. Designed By: Johnny M. Jessup, FFA Advisor Hobbton High School