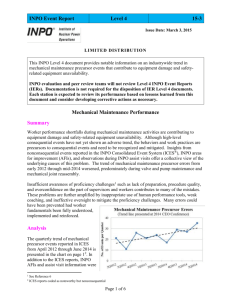

INPO Update on CM Performance

advertisement

INPO Update CMBG Meeting June 2013 2013 Department Focus Areas • Engineering Fundamentals and Technical Authority • Vendor Product Quality • Digital Projects / Cyber Security • Seismic / External Events • AC Power Reliability 2013 Ongoing Work Efforts • Principles, Objectives, and Criteria Revision EN.1, Engineering Fundamentals EN.2, Technical Authority • Updated CM.1, Margin Management Recognizing when your current design basis may need to be changed Fukushima Open Phase conditions Seismic Events Flooding 2013 Ongoing Work Efforts • Transitional CM for New Construction Plants Need CM controls / programs that use technology • Revised Evaluation Guidelines and Procedures Evaluation Guidelines Support Focus Areas 4 Engineering Fundamentals and Technical Authority Engineering Fundamentals Engineering personnel apply essential knowledge, skills, behaviors, and practices needed to ensure: • Equipment performs as required • The plant is maintained within design requirements • Margins are controlled • The plant is operated safely and reliably 6 Engineering Fundamentals • Five principle level categories of engineering fundamentals Monitor and Evaluate Operate, Maintain, and Modify in a Controlled Manner Communicate, Advise and Advocate Acquire and Maintain Expert Knowledge Critical Thinking, Decision-Making, and Challenging 7 Must Know OE - MKOE • Part of Performance Objectives & Criteria • A collection of the most important OE documents issued since 1980. Engineering MKOE is found in INPO 12-005. • As discussed in Recommendation 2 of SOER 102, Engaged, Thinking Organizations MKOE should be included in initial and continuing training for supervisors 8 Vendor Product Quality Vendor Product Quality Working Meeting in April 2012 Selected A/E firms and Various Utilities Collected best practices for the different blocks in the flowchart Issued Evaluation Guideline for Vendor Oversight / Engagement Project Initiation & Project Performance Terry Schuster Ralph Schwartzbeck Vendor Product Quality • INPO 90-009, Conduct of Design Engineering Revised for Cyber, Digital, and Vendor Quality Good Practices (Nov. 2012) Examples of Appendix C (new): • Identify, document, and communicate expectations between engineering vendors and the requesting organization • Perform a feasibility study to identify the best solution 11 Vendor Product Quality • Perform licensing review prior to starting design work • Develop a road map of applicable standards, procedures, and best practices. Communicate this to the engineering service providers • Determine hardware lead time impacts on project schedules • Document and communicate expectations for project and deliverable quality 12 Digital Projects / Cyber Security Digital Projects Digital Project Guidance Modification Testing FMEA Analysis Integration of Digital Equipment Bill Nowicki Ralph Schwartzbeck Gary Garrett Doug Kinsman Digital Projects Recent Industry Workshop – May 2013 IER L2-11-2 Scram Analysis and IERL4-12-87 Causes of Digital Upgrade-Related Events Community of Practice Webpage Pilot Review Visits 15 Digital Projects Communication / Technical Leadership (from IER 12-87) • • • • Vendor Interface and Oversight Technical risk assignment and monitoring Project personnel knowledge and experience Supervisor assignment and monitoring of project engineering activities 16 Digital Projects Community of Practice Used to Share Issues Unique to Digital Modifications Design Project Issues May Occur Prior to Installation Pilot Review Visits Two sites approved in 2013 17 Cyber Security Created Cyber Security Training NANTeL Awareness (general) CSAT (assessment team) Technical (OPS, MA, Design Engr., Engr. Support) Added Digital/Cyber event codes in EPIX 2013 Plant Evaluations will include cyber security Waterford and Beaver Valley Plant Evaluations 18 Cyber Security Scope of Cyber Security Program Safety-related, Important to Safety Security Emergency Preparedness Support systems (BOP) and equipment, which if compromised, would adversely impact configuration control and plant operations 19 Seismic / External Events Seismic Update How-To has been developed and is being used. No real issues with sites compliance; use with IER L2-12-12 response IER L4-13-3 issues for NAPS Lessons Learned EPRI NP-6695 has been supplemented with TR 1025288 External Events • PO & C include - External Events (CM.1) 11 Evaluation Activities Beyond Design Basis Event Cliff edge effects • IER on Fukushima Lessons Learned: – Out for Review • IAEA promotes doing Periodic Safety Reviews every 10 years 22 External Events • Post-Fukushima NRC Near Term Task Force Recommendations (2.1, 2.2, and 2.3) • Items 2.1 and 2.3 are being performed now; NRC Request for Information, issued March 12, 2012 Summary of Industry Results (NRC Follow-ups) Capability to Mitigate Fires in Large Areas of Plant Licensee Capability to Mitigate Design Basis Internal and External Events 23 AC Power Source Reliability AC Power Source Reliability Joint Focus Area with Equipment Reliability Event LOOP Matrix Reviews Joint TSG / EDG Reviews Shawn Simon Evaluator Guideline (How To) Issued Identify vulnerability to design related risk Checklist Attachment 3, Evaluator Checklist Ralph Kothe IER Focused on Causes / Contributors Target June 2013 Steve Swanson 25 EN/CM Department Staff Engineering and Configuration Management Organizational Chart Liaison Engineers Bob Gambrill Manager Ginny Clegg Admin Asst II Scott Hawn Assistant Manager Jean Kuo (Taiwan Power) Ralph Kothe (Bruce Power) Kris Mertens (Electrabel) Loaned Employees Ralph Schwartzbeck Section Manager Digital Systems Permanent Employees Rick Rohrer Bill Nowicki Gary Garrett Bob Burnham Terry Schuster Mark Fowler Doug Kinsman Steve Swanson Tom Trepanier Gary Modzelewski Shawn Simon Craig Faulkner Tim Riddle John Titrington