Title, 24 pt, Tahoma Bold White - Win Cubed

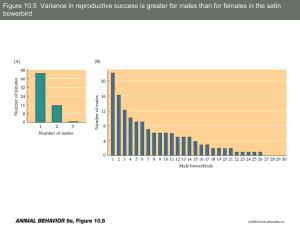

advertisement

COIN Soap Box Meeting #5 (SBM#5) Downhole Control Line Wet Connectors: Hydraulic, Electric And Fibre Optic Connectors…. Are They Reliable Completion Options Today? June 1, 2011 Topic: Permanent downhole pressure & temperature gages (DHPG) and related wet and dry mate connectors • Experience from 60 deepwater subsea wells in GOM spanning 10 year period • High failure rates were experienced initially, 40% failure rate within 6 months, 60% within 2 years, but some within weeks • Extensive RCFA study conducted between Operator, Tree vendor and DHPG vendor • After RCFA study and design/process improvements, achieved near 100% survival reliability We put you first. And keep you ahead. 96 84 72 60 48 36 24 12 6 3 operational time [months] 120% reliability [%] 100% 80% 60% 40% 20% 0% GEN-1 '93-'96 GEN-2 '96-'99 GEN-3 '99-'01 GEN-4 '01-Sept '04 GEN-5 '03-Sept '04 GEN-2 '96-'99 incl DVA We put you first. And keep you ahead. Economic Importance of Functional DHPGs: • Downhole pressure & temperature gauges installed to collect valuable reservoir data • Permanent DHPG serve as "eyes and ears" for the production engineer to assess well performance • DHPGs are expensive, but data particularly valuable during initial production • NPV of project can be improved by $MM with working DHPGs We put you first. And keep you ahead. Background Information on Failures: • High frequency of DHPG failures, some lasted only a few weeks • Diagnostic tests suggested a short circuit near the subsea tree / tubing hanger location (indicated via TDR tests) • Damaged insulation on wiring suspected (nicks seen on electrical pass-through wiring damaged during assembly operations) • Leakage of seawater into system, or condensation within passthrough bores, also suspected as potential cause of delayed failures • Unable to definitively diagnose problems in-situ (inaccessible) • Formal Root Cause Failure Analysis project conducted to evaluate most probable failure modes and root causes We put you first. And keep you ahead. The DHPG is a complete “system”. This is not a commodity item, but is an engineered product requiring the same rigor that we do for all our subsea kit. Key to success was the full integration with all vendors and engineers/stakeholders/contributor s from design thru execution and start up We put you first. And keep you ahead. Potential Root Causes Identified: • Seawater ingress between male/female interface of wet mate coupling (misalignment or damage during installation) • Damaged insulation on wire passing through tubing hanger (damaged at assembly or later from vibration) • Damage to or contamination of rubber boot over soldered connection on dry mate (plus condensation in TH pass-through bore) • Damage to seals between dry mate and downhole electrical cable (TEC tubing) allows seawater ingress • Degradation of elastomer seals due to solvents and or well chemicals We put you first. And keep you ahead. Tubing Hanger Electrical Feed-through: • Tubing hanger manufactured by tree vendor, electrical connectors and penetrators provided and installed by separate vendor • Original DH circuit passed through tubing hanger via small loose wire between wet mate (on top) and dry mate (on bottom) • Thin insulation on electrical wire easily damage when installing past threads in tubing hanger bore • Extra length of wire required for access to solder dry mate to wire when installing through tubing hanger • Difficult installation procedure working on large tubing hanger at wellhead shop • Pushing extra wire back into threaded hole in tubing hanger proved to be a trickey operation • “Bunched up” wire pressing against rough bored surface could cause delayed damage to insulation and short circuit • Multiple nicks on wire insulation observed during course of projects We put you first. And keep you ahead. Tubing Hanger Electrical Feed-through (Cont’d): • Difficult soldering operation to connect pass-through wire to dry mate on bottom of tubing hanger • Rubber insulating boot over soldered joint may not seal if surfaces contaminated during soldering operation • Discovered solvents used to clean up soldering flux might damage rubber insulating boot and/or act as conductor • Condensation within cavity in tubing hanger could cause delayed failure if rubber boot on solder joint is not sealing properly • Protective shipping cap sometimes left off dry mate connector below tubing hanger, allows contamination of "clean" internal surfaces We put you first. And keep you ahead. Tubing Hanger Feed-Through Improvements: • Redesigned tubing hanger to eliminate 2-piece electrical penetrator • Replaced with integral mandrel penetrator unit that is easier to assemble (can build on work bench rather than in high bay) • Mandrel penetrator integrates wet mate male connector on top and dry mate connector on bottom • Penetrator seals into tubing hanger with static seals We put you first. And keep you ahead. Field Connection of Downhole Cable to Dry Mate below Tubing Hanger: • Slow leakage of seawater into dry mate connector via cable connection could explain delayed failure • Difficult procedure for attaching downhole cable to dry mate on bottom of tubing hanger • TEC (tubing encapsulated metal) downhole cable is stiff and hard to manipulate when making up to tubing hanger • Manual process to cut off excess metal tubing on TEC without damaging electrical wire within • Striping off plastic covering on TEC is also manual process (pocket knife) • Any nicks or flattening of metal tubing on DH cable could interfere with seawater seals in dry mate connector • Limited working space, difficult access, connection made on rig floor (wet, dirty environment) • Installation is typically on rig’s critical path, pressure to finish connection ASAP We put you first. And keep you ahead. Field Connection of Downhole Cable to Dry Mate below Tubing Hanger (Cont’d): • Test port on dry mate connector intended to verify function of seawater seals (connector relies on multiple one-atmosphere seals) • Discovered problem with dry mate test port design: Shoulder on parts could form unintentional seal and prevent the test pressure from reaching the critical seals • Damaged metal tubing or seawater seals would thus not be detected by the pressure test • Ferrule type seals used to exclude seawater are actUally working in reverse direction from normal application • Sealing of the ferrule fitting in this application is highly dependent upon surface condition of TEC tubing (exposed to damage during cutting and stripping) We put you first. And keep you ahead. Wet Mate Alignment and Make Up: • Wet mate female mounted on long flexible extension ("quill") below tree • Wet mate male connector rigidly mounted in top of tubing hanger • Flexibility of quill compensates for machining tolerances & clearances • Some “bent” quills discovered that pushed wet mate female off center • Entry bevel on wet mate female was very small (only accommodated about 1/16" offset) • Centralizing bushing for wet mate allowed "float" but was not spring centered • Bent quills could move wet mate female far enough off center to "crash" when landing on male connector • Corrected the problem by rigorous inspection to detect bent quills at assembly stage • Consider larger entry bevel or spring loaded centralization mechanism for future improvements We put you first. And keep you ahead. Results: • Improved designs for electrical pass-through systems on tree and tubing hanger greatly reduced chance of damage during assembly • Improved design of dry mate connector and field installation procedures ensures proper make up of critical seals • Increased attention to detail at all phases • Eliminated initial failures and short term delayed failures • DHPG reliability now running above 95% We put you first. And keep you ahead. We put you first. And keep you ahead. We put you first. And keep you ahead.