presentation

advertisement

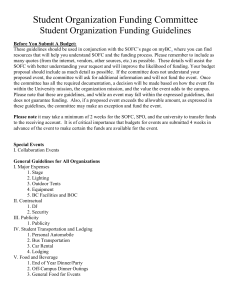

System Concept and Process Layout for a MircoCHP Unit based on Low Temperature SOFC Thomas Pfeifer1, Laura Nousch1, Wieland Beckert1, Dick Lieftink2, Stefano Modena3 (1) Fraunhofer IKTS, (2) Hygear Fuel Cell Systems, (3) SOFCPower 10th European SOFC Forum 2012 Lucerne, June 26 - 29, 2012 © Fraunhofer IKTS What is LOTUS? Low Temperature SOFC µ-CHP System Project of FCH JU (Fuel Cells and Hydrogen Joint Undertaking) 3 year project: January 2011- December 2013 Objectives: CHP system at reduced stack-temperature of 650°C based on ASC technology low cost, mass-produced and proven components high electrical efficiency (min. 45%) and high total system efficiency appropriate solutions for real-world operation © Fraunhofer IKTS -1- LOTUS Consortium European Research, SME and Industry © Fraunhofer IKTS HyGear Fuel Cell Systems (NL) Coordinator, component design and prototyping SOFCPower (IT) SOFC stack development Fraunhofer IKTS (GER) System modeling (steady state, dynamic) and controls Domel (SLO) Gas-air system development University of Perugia (IT) User profile input, SOFC single cell testing EC Joint Research Center (NL) SOFC stack testing, testplan harmonization Associated partner: Vaillant (GER) System requirements -2- LOTUS Design Studies 0-D Stack-Model Parameterization (sofc.dll) U/I-Measurements at varying temperature and fuel-input provided by SOFCPower. Model parameters identified by least squares fit of area specific cell resistance. SOFCPow er S-Design Short-Stack Performance SOFCPow er S-Design Short-Stack Performance 6,0 2,5 No. of cells: 5 á 50 cm² Fuel: 100 % H2 (sat. @ 25 °C) Fuel input: 1.5 slm ≈ 270 J/s Air stoich. ratio: 4.2 650°C (Model) 5,0 700°C (Test) 700°C (Model) 4,5 750°C (Test) 4,0 750°C (Model) 800 °C (Test) 3,5 Cell Area Resistance RAcell / W cm2 Stack Voltage U / V 5,5 No. of cells: 5 á 50 cm² Fuel: 100 % H2 (sat. @ 25 °C) Fuel input: 1.5 slm ≈ 270 J/s Air stoich. ratio: 4.2 650°C (Test) 2,0 65 65 70 1,5 70 75 1,0 75 80 0,5 80 800°C (Model) 0,0 3,0 0 100 200 300 400 500 600 0 700 200 300 400 500 Current Density jel / mA cm-2 Current Density jel / mA cm-2 © Fraunhofer IKTS 100 -3- 600 700 LOTUS Design Studies Stack Performance Estimation at 650 °C SOFCPower ASC700+20% enables LOTUS-development Available Cell Technology: ASC700 66 x 50 cm², CH4-SR Reformate 0.35 0.45 0.40 39.6 (0.60) 0.9 0.8 0.25 0.30 0.5 0.6 0.7 Expected Development: ASC700+20% 66 x 80 cm², CH4-SR Reformate 25 A el = 0.50 ASC700 +20% , S-Design (80 cm²), 66 Cells Aact = 66 x 80 cm² / T Cell = 650°C T = 650°C / T = 550°C 0.4 Fuel 300 Nl/min 42.9 (0.65) 42.9 (0.65) 200 Nl/min 800 W 0.15 15 A 49.5 (0.75) PDC = 400 W 56.1 (0.85) I= 5 A 59.4 (0.90) 500 1000 © Fraunhofer IKTS 1500 600 W VAir,ad = FU = 0.2 100 Nl/min ASC700, S-Design (50 cm²), 66 Cells Aact = 66 x 50 cm² / T Cell = 650°C TFuel = 650°C / T Air = 550°C Stack Voltage | Average Cell Voltage [V] Stack Voltage | Average Cell Voltage [V] 0.3 52.8 (0.80) 3000 2500 Fuel Input [J/s] 3500 4000 45 A 4500 0.7 0.6 500 Nl/min 46.2 (0.70) 35 A 0.55 30 A 1600 W 0.5 400 Nl/min 0.30 1400 W 300 Nl/min 49.5 (0.75) 0.60 1550 WDC @ 70% FU UCell = 0.7 V 52.8 (0.80) 0.4 0.25 25 A 1200 W 200 Nl/min 20 A 0.3 0.20 1000 W 0.65 VAir,ad = 15 A FU = 0.2 59.4 (0.90) 500 5000 -4- 700 Nl/min 600 Nl/min 1800 W 0.35 40 A 56.1 (0.85) Fuel: CH4-SR @ 650 °C, S/C = 1.5, = 0 7.2% CH 4 / 60.6% H 2 / 14% H 2O 12.4% CO / 5.9% CO 2 / 0% N 2 0.40 50 A 0.8 800 Nl/min 2000 W 2 LHV = 238.98 kJ/mol 2000 el = 0.50 LHV = 238.98 kJ/mol 0.55 650 WDC @ 70% FU UCell = 0.7 V 10 A Air Fuel: CH -SR @ 650 °C, S/C = 1.5, = 0 4 7.2% CH 4 / 60.6% H 2 / 14% H 2O 12.4% CO / 5.9% CO / 0% N 2 20 A 46.2 (0.70) 0.45 0.9 39.6 (0.60) 0.20 1000 W I = 10 A 400 W 1000 1500 2000 2500 3000 Fuel Input [J/s] 100 Nl/min PDC = 800 W 600 W 3500 4000 4500 5000 LOTUS Stack Development Recent Test-Results by SOFC Power short-stack performance improvement is demonstrated under H2/N2 mixture 700°C © Fraunhofer IKTS 650°C -5- LOTUS Design Studies Evaluation of Fuel Reforming Options Stack-Internal Reforming (IR) Fuel IR-SOFC H2O Pre-Reforming Steam Reforming (SR) Fuel H2O SR SOFC POX Heat Autothermal Reforming (ATR) Fuel H2O 800 °C 650 °C ATR ATR ATR SOFC POX SOFC POX Air Partial Oxidation (POX) Fuel Air SR Heat © Fraunhofer IKTS -6- SR LOTUS Design Studies Boundary Conditions for the LOTUS System Design stack temperature predetermines reforming temperature 650 °C soot-free reformer operation requires S/C ~ 2 .. 3 in practical µCHP-operation a lower system S/C is essential controlled stack-internal reforming (IR) is beneficial for system efficiency for start-up and shut-down of ASC a reducing atmosphere > 300 °C is required part load operation and independent control of power to heat ratio is beneficial for system economics LOTUS system design is governed by the fuel reforming concept and its process integration © Fraunhofer IKTS -7- LOTUS System Design Process Flow Diagram (PFD) Implementation of the LOTUS Fuel Reforming Concept ~ = SB Start-up Burner fuel bypass (FBP) for controlled stackinternal reforming downscaled steam reformer (SR) SR directly heated by burner exhaust (AB or SB) optional use of oxidative steam reforming © Fraunhofer IKTS Electricity FBP Fuel Bypass SR Steam Reformer Fuel SOFC Stack AB Afterburner APH Air Pre-Heater Air EVP Evaporator Water CHP-Hx Heat Exchanger Heat Exhaust -8- LOTUS Process Layout System Performance Estimation © Fraunhofer IKTS -9- LOTUS Component Development Steam Reformer Pre-Test supports coated with reformer catalyst © Fraunhofer IKTS reformer test rig … - 10 - LOTUS Component Development Burner Pre-Test control panel for testing of the dualuse burner prototype © Fraunhofer IKTS test-rig and model of dual-use burner - 11 - LOTUS Component Development Blower Development two stage high pressure blower with EC motor- prototype © Fraunhofer IKTS CFD simulation of the two stage high pressure blower - 12 - Outlook Next Steps in the LOTUS-Project Description Timeline System component development: system BOM, component design and specification (HyGear) 09/2012 Stack development: design freeze, pre-testing and delivery of full-scale ASC stack (SOFCPower) 12/2012 Dynamic process model implemented in Modelica + software state machine for control logic development (IKTS) 12/2012 Prototype setup and commissioning (HyGear) 06/1013 System testing (HyGear & IKTS) 12/2013 © Fraunhofer IKTS - 13 - Thanks for your attention! www.lotus-project.eu © Fraunhofer IKTS - 14 -