Lecture-05 - LearnEASY

advertisement

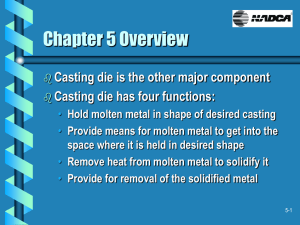

ENMAT101A Engineering Materials and Processes Associate Degree of Applied Engineering (Renewable Energy Technologies) Lecture 5 – Casting Process Casting iron in a sand mould: Wikipedia www.highered.tafensw.edu.au TAFE NSW -Technical and Further Education Commission Casting Reference Text Section Higgins RA & Bolton, 2010. Materials for Engineers and Technicians, 5th ed, Butterworth Heinemann Ch 5 This lecture follows exactly with Higgins Chapter 5. EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission Ingot casting (Higgins 5.2) Cooling a thick casting causes poor grain structure. Large ingots are a problem. Grains in cast aluminium www.spaceflight.esa.int EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission Low Pressure Metal Casting (Higgins 5.3 Sand-casting) VIDEO Metal casting: Sand Moulds Scutt, Don. [Chadstone, Vic.] : Double D Technical Productions, c2004. DVD (29 min.) This program covers jobbing moulding, cold box moulding, pit moulding, rapid prototyping, investment casting, medium volume green sand moulding, automated cold box moulding, hot box moulding, high volume lost foam moulding, hunter process, disamatic. Mt Druitt College Library: DVD 671.252/META Recommended Viewing: All sections. 5.6 Investment-casting 5.7 Full-mould process (Lost foam) EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission Porosity in Low Pressure Porosity occurs because the casting shrinks on solidification. High pressure can fix this, but it makes the mould very expensive. Another way is to use a reservoir of molten metal that feeds more liquid as it solidifies. In this low pressure casting, aluminium alloy was poured down the runner into the mould. The hollow in the top of the runner caused by liquid flowing from the runner into the mould as the casting solidified. As well as the hollow at the top, you can see some holes in the runner and one hole within the casting itself. The runners and risers will later be cut off and discarded. http://openlearn.open.ac.uk EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission High Pressure Metal Die Casting (Higgins: 5.4 Die-casting) VIDEO Metal casting: Die Casting Scutt, Don. [Chadstone, Vic.] : Double D Technical Productions, c2004. DVD (29 min.) This video shows six casting processes and outlines the advantages, limitations and areas of application of each process. Included are gravity casting high pressure hot chamber die casting, high pressure cold chamber die casting and squeeze casting. Mt Druitt College Library: DVD 671.253/META Recommended Viewing: All sections. 5.4.1 Pressure die-casting 5.4.2 Gravity die-casting 5.5 Centrifugal casting EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission (Higgins: 5.9 The choice of casting process) In order of precision: In order of melting point: 1. Investment-casting 2. Die-casting 3. Sand-casting 4. Full-mould process 1. Investment-casting 2. Sand-casting 3. Die-casting EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission Metal Casting Processes Wikipedia: Casting EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission (Higgins: 5.9 The choice of casting process) The initial costs of mould and equipment are higher in the case of die-casting (B) than for sandcasting (A). Labour costs are higher for sand casting. The break-even value, i.e. the number of castings which must be made before the use of die-casting is justified, may be of the order of several thousands. Once the break-even value has been reached, the cost per diecasting becomes less than the cost per sand-casting. Higgins Fig 5.8 EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission Shrinkage Allowance Grey cast iron Contraction (%) 0.7 to 1.05 White cast iron 2.1 Malleable iron 1.5 Steel 2.0 Brass 1.4 Alluminium 1.8 Aluminium alloys 1.3 to 1.6 Bronze 1.05 to 2.1 Magnesium 1.8 Zinc 2.5 Manganese steel 2.6 Metal Atoms in a solid fit closer together than in a liquid, so shrinkage occurs. A few substances expand when they solidify because they have a very loose packing arrangement. E.g. Water (ice), and Silicon. Based on; http://www.calculatoredge.com EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission Design Study Learning Space > All Units > Engineering and Technology > T173_2 > Manufacturing > PART 2. Casting: 2 Casting 2.1 Introduction 2.2 Properties for processing – casting 2.3 Types of casting 2.3.1 Permanent pattern 2.3.2 Permanent mould 2.3.3 Expendable mould and pattern 2.4 Casting processes 2.5 Casting metals 2.6 Casting plastics 2.7 Casting microstructure and defects 2.8 Casting our gearwheel http://openlearn.open.ac.uk/mod/oucontent/view.php?id=399740&section=2.1 EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission Online Properties Resources. Graphical comparison of materials properties. DoITPoMS: Dissemination of IT for the Promotion of Materials Science Wikipedia: Casting Metal Grains and processing EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission GLOSSARY Binders Break Even Charge Cope Core Draft Drag Feeder Fettling Flash Gas Porosity Gate Green Sand Impurity Inclusion Investment Casting Ladle Lost Foam Parting Line Pattern Riser Sand Casting Shrinkage Shrink Hole Sink Marks Slag Sprue Vacuum Casting Castings Glossary EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission QUESTIONS Moodle XML: Some questions in 10107 Processing 1. Define all the glossary terms. 2. List 2 advantages that casting offers over other manufacturing processes. 3. List in a table the advantages/disadvantages of casting processes: Sand, investment, gravity die and high pressure die. Include melting point, accuracy, setup costs, production costs, design limitations. 4. Sand casting pattern and sand mould costs $1900 and each part costs $50 in labour. Die casting mould (die) costs $25000 and per part is $10. Calculate the break-even quantity where die-casting becomes cheaper than sand casting. 5. Explain the following casting terms: Flash, porosity, feeder, runner, draft, ejectors, cores. EMMAT101A Engineering Materials and Processes TAFE NSW -Technical and Further Education Commission