Chapter 5

advertisement

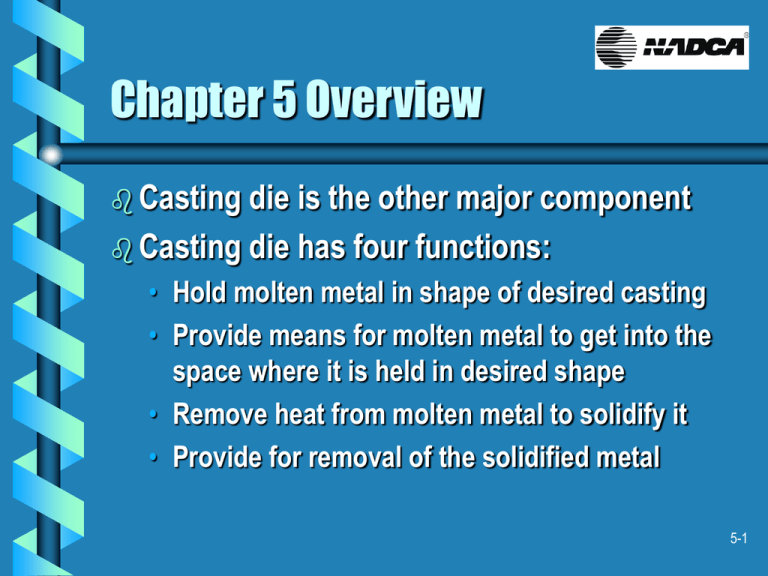

Chapter 5 Overview Casting die is the other major component Casting die has four functions: • Hold molten metal in shape of desired casting • Provide means for molten metal to get into the space where it is held in desired shape • Remove heat from molten metal to solidify it • Provide for removal of the solidified metal 5-1 Chapter 5 Objectives Identify the four types of casting dies Identify the three major casting die modules Identify the purpose of each major die component 5-2 New Terms Cavity • The void or empty space in the die that fills with metal to make the casting Gate • The smallest restriction in the alloy flow path, located at the edge of the casting OEM • Acronym for Original Equipment Manufacturer Overflows/lifters • Small pockets of alloy located around the edge of the casting 5-3 New Terms cont. Runner • Die cast alloy distribution system within the casting die Shot • All the injected material Vacuum vent • Helps get the air out of the die cavity. Vent • Path from the die cavity to outside the die 5-4 Die Ownership The OEM owns the tooling required to make the die casting • If GM opted to purchase casting from a custom producer, the custom producer would buy casting die from a toolmaker and then sell the die to GM • If GM opted to manufacturer the casting in its own plant, GM would buy the die from a toolmaker directly 5-5 Types of Dies Single cavity die • Produces one casting at a time Multiple cavity die • Produces more than one casting at a time Family die • Produces a number of different parts Unit die • OEM owns the unit die and the custom die caster owns the mold base or unit die holder 5-6 Unit Die System Advantages • Lower tooling costs • Shorter lead times • Potentially lower piece part costs Disadvantages • Reduced flexibility in part design • Limited size • Possible problem moving tooling from one vendor to another without additional tooling costs 5-7 Mold base Steel envelope that is designed to hold all the other die components together Usually made from a pre-hardened steel such as a P-20 or AISI 4140 5-8 Stationary half mold base Acts as container for stationary die cavities Provides means for attaching stationary die half to machine Couples injection system to the die Provides a means for aligning to two die halves Has several components 5-9 Stationary Half Mold Base Components Clamp slots Guide pins Pryslots Mounting/clamp plate 5-10 Moving half mold base Acts as container for the die cavities Couples ejection system to the cavities Provides means for aligning the two die halves Components include: • Guide bushings 5-11 Ejector box Provides a means for mounting moving half mold base to moving machine platen Supports moving half mold base against machine closing force and force of injection Couples machine ejector system to die ejector system Has several components 5-12 Ejector Box Components Parallels/rails Clamp plate Support pillars 5-13 Ejector system Inside the ejector box Provides one of four critical die functions, to ‘provide for removal of the solidified metal’ Has several components 5-14 Ejector System Components Ejector pins Return pins Ejector plate Ejector return plate Guided ejection 5-15 Die Cavity Cavity blocks Core pins Slides Casting Carrier Wedgelock Cam pin Cooling lines Heaters Core pin 5-16 Die Cavity cont. Several cavity features share same terminology as the die cast shot • • • • • Sprue Runner Gate Overflows Vents 5-17 Miscellaneous Components Biscuit block Sprue bushing Sprue post Stop buttons Quick eject cam and pins 5-18 Summary Casting die is the other major component • Has four functions Castings can be manufactured by the OEM or purchased from a custom producer 4 casting die forms: single cavity, multiple cavity, family and unit A typical die contains 3 modules: stationary mold base, moving mold base and ejector box 5-19 Summary cont. Unit dies are not complete dies; have certain advantages and disadvantages for the OEM There are many components to casting dies • • • • • • Mold base Stationary half mold base Moving half mold base Ejector box Ejector system Die cavities 5-20