An All LED Theatre - Vincent Lighting Systems

Photo ©David French. Used with permission.

AND THE ANSWER IS…

IT CAN BE DONE!

HOW MUCH MONEY YA GOT

?

FROM WHICH BUDGET?

THE PROGRESS OF LED TECHNOLOGY

HAS MADE THIS A VALID QUESTION

• IMPROVED LIGHT OUTPUT

• RGBAW AND MORE

• HOMOGENIZED BEAM

• REDUCED MATERIAL COST

• FOCUS ON LUMINAIRE DESIGN

• FINDING THE HOLY GRAIL

WHY LED IN THEATRE?

REDUCING POWER DENSITY IS NOT THE DRIVING

FORCE AS IN ARCHITECTURAL LIGHTING; DUTY

CYCLE IS GENERALLY NOT THERE - STAGE

LIGHTING IS NORMALLY EXEMPTED BY ENERGY

CODES

OPERATIONAL ADVANTAGES OF LED ARE THE

DRIVING FORCE FOR ADOPTION IN

ENTERTAINMENT LIGHTING AS MUCH AS

PAYBACK ISSUES, MAYBE MORE SO

OPERATIONAL ADVANTAGES

No re-lamping means greater reliability, key halogen lamps in a theatre are still 300 hours life!!

No expendable color media hassle, gels burn out

Unlimited color selection, cue by cue

Fewer lighting sources required

Can use home made gobos

Cooler, therefore safer fixtures

Much more flexibility from a fixed repertory light plot than a similar plot using conventional instruments

Fixture by fixture control, regardless of circuiting

The major traditional theatrical lighting instrument types now have

LED counterparts

WASH LUMINAIRES

USED FOR COLOR WASHES

TRADITIONALLY PARS OR FRESNELS

ONE OF THE FIRST TYPES TO HAVE A VIABLE LED

EQUAL

RGB IS ACCEPTABLE HERE

Border Lights

STILL USED FOR COLOR TONING AND

SOMETIMES FOR LIGHTING BACK DROPS

TRADITIONAL SOURCES ARE HUGE WATTAGE

HOGS

TRADITIONAL FIXTURES HAVE “PAR-LIKE”

DISTRIBUTION - EASY FOR LED

SATURATED COLORS PREFERRED - EASY FOR LED

CYC LIGHTS

TRADITIONAL EVOLUTION FROM BORDER

LIGHTS, THINK WALL WASH FIXTURE,

ASYMETRICAL REFLECTOR

TRADITIONAL SOURCES ARE HUGE WATTAGE

HOGS AND REQUIRE MANY CIRCUITS

SATURATED COLORS PREFERRED - EASY FOR LED

AUTOMATED LIGHTING

MANY TYPES EXIST, BUT THE WASH

LUMINAIRES NOW HAVE VIABLE LED

EQUALS

TRADITIONAL SOURCES ARE HID - VERY

HIGH LAMP COSTS, MAINTENANCE ISSUES

SATURATED COLORS PREFERRED - EASY

FOR LED

“PROFILE” SPOTS (ERS)

THE HOLY GRAIL, JUST NOW COMING ON THE MARKET FROM MANY

MANUFACTURERS

HARD EDGE SOURCE WITH INTERNAL FOCAL POINT, TRADITIONALLY

ACHIEVED WITH ELLIPSOIDAL REFLECTOR

USED FOR FRONT LIGHTING, LONGER THROWS AND PATTERN PROJECTION

THE WORK HORSE IN EVERY THEATRE

ACHIEVING THE REQUIRED BEAM CHARACTERISTICS HAS BEEN A

CHALLENGE

USED TO LIGHT ACTING AREAS - PASTELS AND FLESH TONES ARE MORE

IMPORTANT THAN SATURATED COLORS - THIS REQUIRES RGBA OR RGBAW

HOUSE LIGHTS

FULL RANGE DIMMING REQUIREMENTS HAVE DICTATED HALOGEN SOURCES

HOUSE LIGHTS ARE TYPICALLY VERY DIFFICULT TO SERVICE

HALOGEN SOURCES DRIVE THE NEED FOR DIMMER CABINETS THAT OTHER-WISE MIGHT NOT BE

NECESSARY

THERE ARE NOW LED SOURCES AVAILABLE FOR HIGH CEILING APPLICATIONS THAT ALSO

INCORPORATE FULL RANGE DMX DIMMING

0-10 VOLT OR ELV DIMMING MAY BE ACCEPTABLE IN CAFETORIUMS OR OTHER VENUES WHERE

FULL DIMMING IS NOT AN EXPECTATION

SOME FIXTURES TAKE ADVANGE OF RGBW TECHNOLOGY TO ALLOW HOUSE LIGHT COLOR-

MIXING

DMX CONTROL ALLOWS FLEXIBILITY IN CONTROL ZONES MUCH THE SAME WAY DALI AND

ADDRESSABLE BALLASTS ALLOW IT IN ARCHITECTURAL LIGHTING

HOW DOES LED AFFECT

SYSTEM DESIGN?

THIS IS NOT YOUR DADDY’S

STAGE LIGHTING SYSTEM

WE ARE ON THE EDGE, OR

MAYBE PAST, A SEISMIC SHIFT

IN SYSTEM DESIGN

IS YOUR PROJECT A

CANDIDATE TO MAKE THE

LEAP?

TRADITIONAL

SYSTEMS

CENTRALIZED DIMMER RACK

FEEDING DISCREET CIRCUITS

CIRCUITS ARE DISTRIBUTED

BASED ON THE NEED FOR

CONTROL FLEXIBILITY AS MUCH

AS LOAD REQUIREMENTS

QUANTITY OF CIRCUITS OFTEN

DROVE FEEDERS TO LARGER

SIZES OUT OF LINE WITH

ACTUAL LOADS

WHAT IS DIFFERENT

WITH LED?

SMALLER FEEDS

REDUCED NEED FOR

CONVENTIONAL DIMMING

NEED TO TURN POWER SUPPLIES

OFF - PHANTOM POWER ISSUES

WHERE DIMMING IS REQUIRED IT

CAN BE ACCOMPLISHED USING

DISTRIBUTED DIMMING DEVICES

NO NEED FOR K-RATED

TRANSFORMERS

REDUCES LOAD ON AIR-

CONDITIONING SYSTEMS

CONTROL IS KEY

EACH FIXTURE AND ITS ATTRIBUTES ARE

CONTROLLED DISCREETLY VIA DIGITAL

SIGNALS, TYPICALLY DMX

DMX DATA NEEDS TO BE DISTRIBUTED

THROUGHOUT THE SPACE THROUGH

THE USE OF SPLITTERS OR ETHERNET

EACH FIXTURE CAN TAKE MORE THAN A

DOZEN CHANNELS OF CONTROL

CONTROL CONSOLES EXIST TO MAKE

CONTROLLING ALL OF THIS EASIER

WHAT ABOUT THE DOLLARS?

SEVERAL FACTORS TO CONSIDER

LUMINAIRE COST

REDUCTION OF DIMMING EQUIPMENT

INSTALLATION SAVINGS

OPERATIONAL COST SAVINGS

LUMINAIRE COST

20 – 30 % FEWER LUMINAIRES REQUIRED

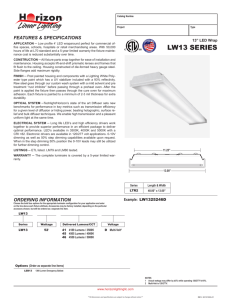

WASH FIXTURES:

CONVENTIONAL: $100 - $300

LED $500 - $1,500

BORDER LIGHTS (not specified much now)

6’ R40 - $600.00

LED - $2,500 - $4,500

Yes, really

CYC LIGHTS

CONVENTIONAL 1000w FOUR CELL UNIT- $1,400

LED - SINGLE CELL - $1,200 - $1,800

LUMINAIRE COST

AUTOMATED LIGHTING WASH FIXTURES

CONVENTIONAL $1,500 - $10,000

LED $2,000 - $10,000

PROFILE

CONVENTIONAL - 575 watt 19-50 degree - $350

LED $1,000 - $3,500

Yes, really

HOUSE LIGHTS

CONVENTIONAL 500W T4 $300 - $500.00

LED $1,000 – 1,500.00

REDUCTION OF DIMMING AND RELATED

EQUIPMENT

• 96 CIRCUIT DIMMER RACK - $20,000

• K-RATED TRANSFORMERS NOT REQUIRED

• ELIMINATION OF DIMMER ROOM

• DISTRIBUTED DIMMING AND RELAYS

• SMALLER FOOTPRINT

• LESS LOAD ON AIR-CONDITIONING EQUIPMENT

INSTALLATION SAVINGS

• REDUCED LOADS MEAN SMALLER FEEDERS

• FEWER CIRCUITS REQUIRED

• CAN USE COMMON NEUTRALS IN SOME

CASES

• NEED TO DISTRIBUTE DATA, BUT WE ARE

ALREADY DOING THAT

• MAY REDUCE THE NEED FOR ACCESS TO

EQUIPMENT

COMPARISONS

Used 200 days per year, 6 hours per day, 60% diversity,

.15/kW hour

Consumables such as lamps based on published hours

TYPICAL HIGH SCHOOL - CONVENTIONAL

EQUIPMENT COST - $139,000.00

INSTALLATION AND YEAR ONE COST - $88,116

TOTAL - $227,116

ANNUAL OPERATING COSTS - $15,516

COMPARISONS

Used 200 days per year, 6 hours per day, 60% diversity,

.15/kW hour

Replacement lamps are not an issue

TYPICAL HIGH SCHOOL - LED

EQUIPMENT COST - $197,482

INSTALLATION AND YEAR ONE COST - $37,954

TOTAL - $235,436

ANNUAL OPERATING COSTS - $2,104

SERVICE LIFE - LED

Assume an L70 of 50,000 hours

Assume usage at 6 hours per day, 200 days per year

Life expectancy would be over 40 years!!

Things break before that - LED equipment is more expensive to replace which must be considered

Annual Operating Savings pays for brand new equipment in about 15 years at today’s dollars

CONCLUSIONS

Very significant operational advantages to an LED theatre lighting system

If you have the budget you can do an all LED theatre

Even if you have a “conventional” budget you can incorporate LED to an extent that is significant enough to drive your system design

Provide for the future use of LED in your system design

Distribute Data

Provide Capacity in the Control System

Provide the ability to turn power supplies off

AN ALL LED THEATRE

QUESTIONS

DISCUSSION

THANK YOU