The Hyatt Regency walkway collapse

advertisement

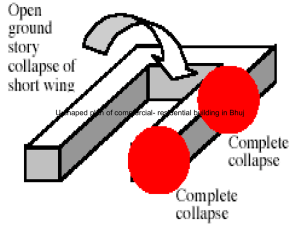

The Hyatt Regency walkway collapse By Dimitrellos George Shang Lin An introduction to a devastating structural failure • on17 July,1981in Kansas City, Missouri, USA • Two suspended walkways collapsed during a dance competition • During the collapse approximately 2000 people were in the atrium • 114 people lost their lives • More than 200 were injured Background information • Hyatt Regency Hotel was designed by the Crown Center Redevelopment Corporation (the owner) in 1976. • Gillum-Colaco, Inc., a Professional Engineering Firm, G.C.E. and the architect, PBNDML Architects, Planners, Inc. G.C.E. were hired to provide all structural engineering services for the implementation of the 750 room hotel project. • In 1978 began Hyatt’s construction. • Havens steel company signed a sub-contract in order to fabricate and erect the atrium steel of the Hotel. Original Design •Three suspended walkways spanned the atrium at the second, third and fourth floor levels. •The fourth floor walkway was suspended from the ceiling by a set of six hanger rods. •The second floor walkway was suspended from the fourth floor directly underneath it by the same set of hanger rods. •The third floor walkway was offset from the other two and was independently suspended from the ceiling by another set of hanger rods. •In the collapse the fourth and second floor walkways fell to the atrium floor ,with the fourth floor walkway resting on the top of the lower walkway. •The third floor walkway remained intact. Figure 1 • • • • • • • • The hanging suspension rods would support upper and lower beams. Two beams run longitudinally would bear the weight of the walkways. In turn, both beams would rest on box beams. The box beams consisted of two 8 inch channel sections welded toe to toe to make up a box beam. The ends of the box beams were drilled to receive the rods. Heavy washers and nuts run up to the rods to support the box beams. The entire length of the rods had to be threaded in order the nut run on it. Threading 10 m rod is difficult and expensive. Original design What cause the failure ? A catastrophic modification ! •Havens Steel changed the design to simplify the assembly task and reduce the cost. •Engineers failed to realize that this modification was doubled the load on the nuts under the top walkway. •90 kN in the original design for each hanger rod. •From the modification, each hanger rod of the top walkway had to carry a load of 180 kN. •The collapse began from the middle box beam of the top floor walkway. Rod ,washer and nut hanging from the ceiling almost intact from the collapse. The deformed 4th floor beam National Bureau of Standards Investigation concluded that: • Collapse of the walkways occurred under the action of loads that were less than the design loads specified by the Kansas building code. • The capacity of the original design was sufficient to resist the imposed loads at the time of collapse. • The change in hanger rod from a continuous rod to interrupted rods doubled the load to be transferred by the fourth floor box beam. An Engineer’s Responsibility • to insure the safety, health, and welfare of the public • follow all codes and standards, and uphold their professional obligations • Safety during the construction phase of projects • The Kansas City Hyatt Regency Walkway Collapse is an incident where construction safety was compromised, leading to the eventual collapse of the walkway. Organizational Structure and Procedure. Who was responsible? 1. A lack of communication between the designer and the fabricator 2. The engineering firm 3. The revised design Responsibility of Design Engineers • Possible reasons for design engineer’s agreeing to the design change: – “fast-track” nature of the project • saving time; • saving money; – avoiding a call for reanalysis; – following his immediate supervisor's orders; – looking good professionally by simplifying the design; – misunderstanding the consequences of his actions; – any combination of the above 14 Responsibility of Fabricators and Contractors • Design by fabricator judgment was motivated by: – Strict adherence to the structural drawings, – as prescribed by the AISI manual, – under the fabricator’s discretion. • The materials selected for the fabrication were standard strength, size, and grade of material, rather than what should have been used to compensate for the added stress of the altered design. 15 Responsibility of Crown Redevelopment Corporation • Failure to issue full on-site inspection of hotel construction after the collapse of the atrium roof months earlier 16 Consequences 1. 114 people were killed and over 200 injured. 2. Many principals involved lost engineering licenses. 3. Engineers were found guilty of gross negligence, misconduct, and unprofessional conduct in the practice of engineering. 4. Expensive legal suits were settled out of court. 5. Several firms involved went bankrupt Summary • From the Kansas City example, the importance of engineer’s responsibility can be seen in aspects ranging from design to construction. • The collapse of the atrium roof during construction was indicative of problems with the overall design. • Engineers should thoroughly review all designs and modifications made during the construction phase to insure the safety of the project. How Do We Prevent Similar Events In The Future highly complex design and construction process Human errors Economic pressures It is axiomatic that someone cannot be held responsible for achieving an objective, without commensurate authority an ineffective change management system To prevent this type of tragedy in the future, A clearly defined organizational structure Clearly defined and enforced process procedures Independent constructability review REFERENCES: • http://en.wikipedia.org/wiki/Hyatt_Regency_walkw ay_collapse • National Bureau of Standards (May 1982). "Investigation of the Kansas City Hyatt Regency Walkways Collapse". US Department of Commerce. Retrieved 2011-01-26. • ^ Baura, Gail (2006). Engineering ethics: an industrial perspective. Academic Press. p. 55.ISBN 978-0120885312. • ^ a b c "Hyatt Regency Walkway Collapse". School of Engineering, University of Alabama. Retrieved 2007-10-03. Questions ?