RCS Product - ASCO Numatics

advertisement

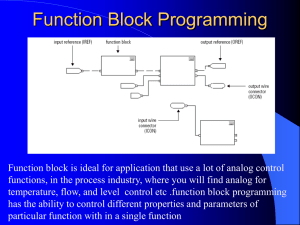

Redundant control system (RCS) Name: Thierry Bakker Project Pursuit manager What is Redundancy? Definitions: Common definition: Surplus to requirements; unnecessary or superfluous Engineering definitions “A device that will provide its intended function upon loss of power.” (2007 NFPA-80) An operation which ensures that a failure of equipment, process, or system does not propagate beyond the immediate environs of the failing entity. Redundant Control System Safety Instrumented Systems Process Reliability Process Valve Diagnostics Redundancy with solenoid valves ++ Safety - - Reliability (production) 1 2 3 1 1oo2 One out of two 2 3 1 2 2oo2 3 Two out of two 1 2 3 ++ Reliability (production) - - Safety Redundancy with solenoid valves 2oo2D 1 2 3 1 2 3 Safety ++ Reliability (production) Reasons for RCS design Redundant SOV commonly used in continuous run processes to prevent spurious trip (Nuisance trip) due to coil failure. Typical Redundant SOV installations:– Do not provide indication of SOV safe failure. – Do not provide online maintenance facilities. – Do not provide the ability to automatically test for “stuck” SOVs or plugged vents. – Do not provide ability to automatically partial stroke test the process valve – Have difficulty meeting SIL requirements. RCS Product Evolution Typical 2oo2 SOV Installation 3 way – Normally closed - Energized SOV1 S Air Supply 2oo2 installation SOV2 S vent Issue: Cannot easily detect failure or its location Block Valve RCS Product Evolution Addition of pressure Switches – Status Indication SOV1 PS1 S Air Supply SOV2 PS2 S vent Block Valve Issue: How do you repair the problem without shutting down the process ? RCS Product Evolution Addition of maintenance bypass Isolation Valves SOV1 PS1 S Air Supply SOV2 PS2 S vent By-Pass valve Issue: 1) How do you know when you are in by-pass ? 2) How do you know when repair is complete ? Block Valve RCS Product Evolution Addition of maintenance bypass PS indication SOV1 PS1 S Air Supply SOV2 PS2 S vent PS3 Block Valve RCS Product Evolution The ASCO RCS Product SOV1 PS1 S Air Supply SOV2 PS2 S vent PS3 Block Valve RCS Concept ASCO’S RCS package consolidates many of the components using known technology to create a more complete package with unique features to meet today's needs… RCS Product Features Ground Din Mounted Terminal • Accommodates up to 14 AWG wiring Keyed Maintenance Bypass • Permits user to service unit without disturbing the process ISO-3 Low Power Solenoids (2) • 4 bolts permit quick replacement • 1.4 watts (24vdc) • Class 1, Div 2 solenoids (non incendive) Pressure Switches (3) • Monitors solenoid valve position (diagnostics) • Class 1, Div 2 • Stainless Steel Air-operated Bypass Valve(1) • Maintains process while main solenoid valves are serviced during bypass Enclosure • 304 or 316 Stainless Steel or Fiberglass • UL Type 4, 4X Breather vent • Limits condensation build-up Pneumatic connections RCS 1oo1HS RCS 2oo2D Normally Closed Version •Normally Closed RCS operates like a 3 way Normally Closed valve •In the de-energized state the unit is venting the process valve actuator •As long as one solenoid valve is energized air is supplied to the process valve. •When both solenoid valves are de-energized the process is vented. •Typical application: “ESD systems” (Emergency Shut-down valve) – Fail Safe Bypass (B/P) valve shown in the normal state SOV1 and SOV2 de-energized SOV1 out SOV2 e out in ps B/P 3 out SOV1 in e ps SOV2 in e ps Inlet e Outlet Exhaust PS1 PS2 PS3 Contact Closed Contact Closed Contact Closed Status:SOV1 & SOV2 de-energized Valve Closed Normally Open Version •Normally open RCS operate like a 3 –way normally open. •In the De-energized state, air is supplied to the process valve •As long as one solenoid valves is energized the process valve will be open to exhaust and remain in the normal position. •Typical application: “vent valves” Bypass (B/P) valve shown in the normal state SOV1 and SOV2 de-energized Outlet SOV1 out SOV2 in out SOV1 e e ps ps in B/P plug in ps e in out e Valve Open Exhaust Air Supply PS1 Contact Open PS2 Contact Open PS3 Contact Closed Status: SOV1 & SOV2 de-energized Double Acting Version • Similar to having one 3 way normally closed valve & 3 way normally open • When both solenoid valves are de-energized one side of the actuator is venting while the opposite side is being pressurized • Customer must define desired position “Fail close / fail open” • If the event of single SOV failure actuator becomes balanced – actuator maintains last position Bypass (B/P) valve shown in the normal state SOV1 and SOV2 de-energized SOV1 • Available only in 2oo2 operation ps out SOV2 e in out e ps For use with valves that have a safe state of open the connections to the valve actuator from the RCS, C1 and C2, would be reversed B/P e in out e ps SOV2 in Air Supply e C2 Exhaust C1 PS1 PS2 PS3 Contact Closed Contact Closed Contact Closed Valve in closed position Valve Safe State Closed RCS Versions Series 5R – No on-board diagnostic processor (AC or DC) Series 5L – with on-board diagnostic processor (DC only) • Main Components • 2 - Solenoid Valves = 2 Digital Output D/O • 1- Maintenance By-Pass • 3- Pressure switches = 3 Digital inputs D/I • Key function Monitor status of SOV’s & bypass •Functional testing capabilities • Automated through PLC or DCS • Manually initiated test • Optional panel mount push button and lights • Initiates program test RCS Versions Series 5L – with on-board diagnostic processor (DC only) Siemens PLC - main Function • reduce programming and total I/O count • Controls outputs to SOV’s • Receives diagnostic input from pressure switches • Provides testing and diagnostic information • Power is supplied to Siemens PLC via the users controller • Testing and diagnostic reporting to any human machine interface (HMI) can be facilitated via MODBUS 485 IMPORTANT: Onboard PLC provides testing and diagnostic information only. • Siemens PLC is benign to the safety action • Power is supplied to the on-board PLC by users controller • User’s controller is always responsible for the safety action • Safety action is executed by de-energizing the output power to Siemens PLC RCS Versions Series 5L – with on-board diagnostic processor (DC only) In the event of a PLC failure Watch Dog Relays •Watchdog relays are provided to prevent de-energizing the SOV’s due to a failure Of the on-board PLC outputs. • Each SOV receives power through a separate normally closed relay contact on separate watchdog relays . • Watchdog relays are energized by a output from on-board PLC • This keeps normally closed contact in the open position • If on-board PLC fails the watchdog relay close and SOV 1 & SOV 2 are connected to controller allowing the controller to have supervisory control over SOV 1 & SOV2 • Power to SOVs is maintained avoiding accidental shutdown • Loss of PLC will be detected and annunciated RCS Product – 1oo1 HS 1. In the 1oo1HS operational mode one SOV is selected as primary and is normally energized. 2. The Hot Standby SOV is normally de-energized and its associated PS verifies the vented state. With only one SOV energized position the safety availability SOV1 is increased.0 Primary S PS1 Air Supply SOV2 Hot Standby S PS2 ZSO vent PS3 Block Valve Normally Closed - De - Energized - to - trip SOV' Status Pressure Switch Indication Solenoid Valves P.S. 1 P.S.2. P.S.3 Both SOV's Energized O O CL Both SOV's De-Energized CL CL CL SOV 1 De-Energized only CL O CL SOV 2 De-Energized Only O CL CL Bypass mode O O O = Closed contact = Open contact RCS Product – 1oo1 HS 1. If the primary SOV shifts to the vented state (coil failure) its associated PS identifies the failure and the Hot Standby SOV is energized. 2. The Hot Standby prevents the closure of the process valve 3 The reliability of the 1oo1HS is the same as 2oo2 operation. SOV1 Primary S PS1 Air Supply SOV2 Hot Standby S PS2 ZSO vent PS3 Block Valve SOV' Status Solenoid Valves Both SOV's Energized Both SOV's De-Energized SOV 1 De-Energized only SOV 2 De-Energized Only Bypass mode CL = P.S. contact is closed O = P.S. contact is open Pressure Switch Indication P.S. 1 P.S.2. P.S.3 O O CL CL CL CL CL O CL O CL CL O O O = Closed contact = Open contact RCS ATEX Certification RCS SIL Certification Certified SIL 3 Capable by Exida for 1oo1HS, 2oo2D • • • • Available as an optional feature on configurator SIL certified units will have a different catalog number than non-SIL units If required, must be identified at the time of part number configuration Currently SIL certification is only available on units without onboard PLC Supporting documentation for certified units: • • • • Exida Certificate FMEDA IEC61508 Assessment Safety Manual RCS in the field The RCS solution combines the benefits of safety and reliability in a single package. “it’s the only pilot valve system that has no single point of failure that can result in an unwanted closure of the process valve. With the RCS, customers will benefit from higher asset availability, less risk of spurious trips, and safe shut downs of mission critical systems, time after time.” The RCS achieves higher levels of safety by incorporating a redundant, fault-tolerant architecture, high diagnostic coverage, and automated testing. Its self-diagnostic capabilities test both the safety system and process valve to ensure continuous proper operating performance. The ASCO RCS was designed to meet the expanding national and international hazardous location requirements for safety systems, high reliability, and critical control applications. It allows the end-user to specify a normally closed, normally open or double acting configuration in redundant control “2oo2” (two-out-of-two) or single solenoid with back-up “1oo1” (one-out-of-one) operation. All types of RCS are available with “automatic on-line testing” of the solenoid valves and “partial stroke testing” of the process valve. The RCS also provides users with a maintenance/ by-pass mode, which permits service to the device without taking the process valve off line. This allows the plant to maintain production without jeopardizing its safety. RCS Information RCS Brochure Contains: • Product specifications • Technical details on RCS operation • Optional features • Introduction to the RCS Configurator Available online @ www.ascovalve.com RCS Configurator “LIVE” demonstration Redundant Control System Safety Instrumented Systems Process Reliability Process Valve Diagnostics