Ganges Group – Brief company Profile

advertisement

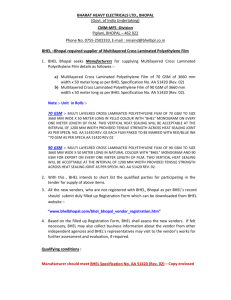

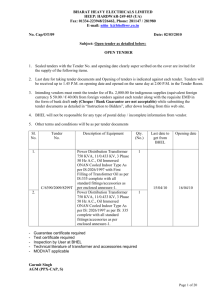

Ganges Internationale Pvt Ltd B36, Lawrence Road Industrial Area, Delhi 110035 Phone: 011-27192696, 47090225 Fax:011-47090227 Email:raipur@gangesintl.com Cell: +91-93454-23867 Ganges Internationale Pvt Ltd, # 163/1, 2-3 floor, K sons complex, Broadway, Chennai 600108 Tamilnadu Phone: 044-65675574 Manufacturing Plant – Raipur Ganges Internationale Pvt Ltd, Vidhansabha Road, Village Saddu, Raipur – 492007 Chattisgarh Contact- +91-9669180005 Manufacturing Plant - Pondicherry Ganges Internationale Pvt Ltd, Sedarpet Industrial estate, Malaum Road, Pudducheery-605111, Pondicherry Phone: 0413-2678366 Introduction •Ganges Internationale (GI) was promoted by Mr Prem Goyal and family and was incorporated in 1991-92. •Awarded as “Best ACF Partner for QUALITY” from BHEL-Trichy in Year 2012. •The group has interests in Steel Tube manufacturing, galvanizing, telecom and transmission tower manufacturing and erection, Flour manufacturing, Bread manufacturing and trading. •Group company Crimson metal (earlier Sri Sarbati Steel Tubes) was approved galvanizer by NTPC for galvanizing BHEL floor gratings since 1990 and had successfully galvanized and delivered thousand’s of tons of fabricated structures. •GI started manufacturing operations in 2004 at Pondicherry and quickly became the market leader in telecom towers in India, We have a joint collaboration with Ramboll, Denmark where we fabricated special towers based on precision engineering using high tensile steel whereby the steel consumed was reduced by 25%. Special tower was made and supplied for 110 mtrs height with Die electric USA which weighed more than 90 MT. Towers manufactured are exported widely and have been shipped Europe, south east Asia and Africa in bulk. •GI has won 3 years special award by Infratel (airtel) for First Time Right which certifies the teams’ achievement in getting 100% quality in 1st attempt and that also on targeted time. Apart from this has regularly got commendation certificates. • Sister companies M/S Ganga Roller flour Mill have been awarded Safety and productivity awards from 1980, and M/S Shakun Consumer products has recently won the best Bread plant Award from Britannia. •Current plant for Heavy engineering was set up in 2010-11 and is being managed by highly experienced personal who have had more than 35 years experience in Heavy engineering and have been manufacturing boiler support structures since 1977. GANGES ON TIME Customer focused mind set at every level 40 Years 1600 People Manufacturing Experience Working under Ganges group 18 Years Rs 700 Crores Steel Industry Experience Group turnover in Y 2011 60,000MT/Yr Combined steel manufacturing capacities of the plants 16 States and 3 Countries Offices in India and overseas 4 Steel Tube Manufacturing – Pondicherry, India Telecom Tower Manufacturing – Pondicherry, India Steel Re-Rolling – Pondicherry, India Roller Flour Mills – New Delhi, India Bread Manufacturing – New Delhi, India Heavy Engineering – Raipur, India Ethical Conduct Deliver the Promise Excellence Team Work Entrepreneurial Spirit Shop floor with 5S concept Everything has a place, everything is in place. Visible performance. Visible improvements Supreme Quality: One Mindset - Don’t receive defects. Don’t make defects. Don’t pass defects. Drive the process to achieve Six Sigma Quality Health and Safety at the core of manufacturing operation. Operator Skills: Prefer multi skilled operators rather than “super specialists” Special awards for best performers. Process capability: Measure process capability - If you can’t measure, you can’t improve. Data based process improvements - Let data speak for itself and not the opinions. Eliminate process waste – Kaizen, TPM, SMED etc. Efficient use of people, material, space and equipment Innovation and creativity: 5 ideas per employee per month. Best idea, Best Reward. Consistent motivation thorough public recognition Learning corners – Mistakes are our best teachers. Learn from it so that it won’t be repeated. * Expansion planned to 20,000MT per annum by March 2014 # Item & Material 1 I Beam (Length varies according to boiler size. Thickness of plates: from 10mm to 63mm) 2 PLUS Beam: (Length varies according to boiler size. Thickness of plates: from 10mm to 63mm) 3 Box Beam: (Length varies according to boiler size. Thickness of plates: from 10mm to 63mm) 4 Auto Weld Structures: (Length varies according to boiler size. Thickness of plates: from 10mm to 63mm) 5 General fabrication Products fabricated so far.. Plus Column & Auto welded Beams General Fabrication : Gantry Duct AW Beam : Maximum Weighted Job Maximum Weighted Jobs Executed DESCRIPTION CUSTOMER QTY SIZE WEB /FLANGE THK MAX WEIGHT PER LENGTH IN PIECE IN KG MM AW Beam BHEL 2 800 x 300- 20/ 63 17678 7,175 AW Beam BHEL 2 900x300- 20/ 50 17432 7,686 AW Beam BHEL 4 800x300- 20/63 17868 7,182 AW Beam BHEL 2 2500 x 600- 40/ 40 19040 21,909 Plus Lift Post BHEL 2 UB 406x170 12150 4,376 AW Beam BHEL 2 2500 x 600- 40/ 40 19040 21,909 Eco Ducts BHEL 1 4000x3500x11500mm 18,472 Modern Equipment H beam straightening machine End Face Milling Machine Welding Rotator CNC Flame Cutting Machine Modern Equipments 1250A SAW machine 500A MMAW machine Electrode Oven High Pressure heating torches Portable Electrode Oven Flux Baking Oven Manufacturing Facilities # Description of machine Capacity & Nos. Year of make Units 1 CNC FLAME CUTTING M/C. 5*16M with 6 torches, Y 2010 01 2 H BEAM STRAIGHTENING & I BEAM Flange Width: 200-1000 MM, Flange Thick Y 2010 TACKING M/C. : 6-80MM, Web Height : ≥350MM, MAX. Straightening Speed: 7.8M/MIN. 01 3 FACE MILLING M/C. Y 2010 01 4 SAW WELDING M/C. Milling Turning Speed:80-400 RPM, Milling Head Power: 5.5 KW, Level Moving Distance: 1500 MM, Vertical Moving Distance:1200 MM, Y 2010 05 5 SMAW WELDING M/C. Power-69 KVA 3 Phase 415V 50Hz, 3 Phase AC 415V 50 Hz Y 2010 36 6 SELF ALIGNED WELDING ROTATOR Max. Loading Wt.:30 T, Applicable Vessels Dia: 500-3500 MM, Wheel Linear Speed: 6- Y 2010 60 m/h, SEMIAUTOMATIC GAS CUTTING Power-AC 220V 50 Hz, Y 2010 M/C. PUG 7 8 FLUX BAKING OVEN 9 ELECTRODE OVEN 02 05 INPUT VOLTAGE:380V, MAX. TEMP.:500 Y 2010 °C, CAPACITY:200KG, RAT. Power:5.2 KW, High Temp.:500 °C, Y 2010 Capacity:100 KG, Socking 0~20h, 02 10 PORTABLE ELECTRODE OVEN DHT-10KG, Y 2010 20 11 GRINDING M/C. MUKITA AG-7, Y 2010 40 12 AUTOMATIC BROUCH DRILLING M/C. 13 PNEUMATIC BLASTING M/C ROLLI WOLF N9B2- 31MM, Y 2010 4 SURFEX PORT1000, Y 2010 01 01 19 Handling Facilities S.No. MACHINE NAME QTY CAPACITY - /TON 1 Gantry EOT 3 15 TON 2 Gantry EOT 5 5 TON 3 HYDRA 4 14 TON 4 HYDRA 3 12 TON 20 Quality and Testing Facilities Sl. No. Description 1 FILLET GAUGES 2 MEASURING TAPES 3 DIGITAL PAINT DFT METER(ELECO METER) Capacity & Nos. Make & year of Mfg. Calibration Status (Y/N) Approval Qualification 3.2-25.4x5units GAI/2010 NA NA Y NABL Tajima (5M x 15, 20Mx10,30Mx5) 0-3000Micon x 1 unit Milhard Y NABL 0-1000 microns Mitutoyo NA NA 0-25mm x 2 units, 2550mm x 3 units,5075mmx2 units Mitutoyo Y NABL 4 MICROMETER (ANALOG TYPE) 5 VERNIER CALIPER Digital 0-200mm x 1unit, Analog 0-300mm x 1 unit Mitutoyo Y NABL 6 BEVEL PROTECTOR 0-180 degrees x 2 Units Mitutoyo Y NABL 7 DYE PENETRATION TEST KIT Cleaner CL96 x 28, PenetratentPT97 x6, Developer DV98x17 Magnaflux NA NA 21 Quality and Testing Facilities (Cont..) Cont… Sl. No. Description Capacity & Nos. Make & year of Mfg. Calibration Status Approval Qualification GAI/2010 NA NA 8 FILLET GAUGES 3.2-25.4x5units 9 RADIUS GAUGE 7.5-15.5 x 2 units, 5-25mm x 2 units NA NA 10 FILLER GAUGE 0.03-1.00mm NA NA 11 HEAT TREATMENT RECORDER Delta Plotter x 1 unit NA NA 12 MAGNETIC FLAW DETECTOR Magnaflux P1500 x 1 unit Magnaflux Y NABL 13 ULTRASONIC THICKNESS MEASURMENT MACHINE Modsonic Einstein II TFT Range 10mm to 5mtr Modsonic NA NA 22 List of Machines S.No. MACHINE NAME QTY 1 2 3 4 5 6 7 8 9 10 11 12 Grinding M/C (AG-7) Arc M/C 47 37 Grinding M/C (AG-4) PORTABLE OVEN 32 30 Magnetic Drilling M/C MIG WELDING MACHING COMPRESSUR - Painting AIR POWER PERMANENT MAGNETIC LIFTER Pug Cutting (CG-1 30C) SAW HS-1250 13 10 6 6 6 5 Angle punching M/C (Hydralic) Broch Cuttng(Drilling) M/C 4 4 13 CNC Number punching m/c COMPRESSUR - Num. Punching m/c Sand Disc Grinder Machine Bench GrInder Bending MACHINE Blasting Vessel CNC PLASMA 4 3 3 2 2 2 2 Compreser -Plasma Cutting m/c FLUX DRYER Oven 2 2 Grinding M/C (AG-7)-48 2 14 15 16 17 18 19 20 21 22 Contd… S.No. MACHINE NAME QTY 23 GROOVE MACHINE(Bevling m/c) 2 24 25 HAND DRILL M/C MAIN PANEL 2 2 26 Pencil Grander 2 27 Pipe Cutting m/c 2 28 Pug cutting multi torch 2 29 Waving m/c 2 30 Welding Rotator 2 31 Airless Spray M/C 1 32 Chanel Cutting M/C 1 33 1 1 37 CNC Angle Punching M/C( APL 16 A-8) CNC FLAME CUTTING ELECTRODE DRYER AUTOMATIC FARINF. WEL End Milling M/C Flange Straighten 38 Hammering Drill M/C 1 39 Hand Drill M/C 1 40 Lathe Machine 1 41 Number punching m/c 1 42 43 Piranha Machine Power Control Panel (APFC PANEL) 1 1 44 Rolling Machine 1 34 35 36 1 1 1 Manpower Analysis Division Status Production Graduate Diploma Skilled 211 Un-Skilled 09 09 Quality Control 04 04 01 00 Planning 04 03 01 00 Human Resource 03 00 01 01 Accounts 03 04 02 00 Purchase & Stores 02 02 04 00 25 22 220 126 Total 125 25 Innovation – Turning Ideas in to Manufacturing Unique I BEAM & PLUS Beam Rotating Fixture Advantages: Total cycle time reduction in Gazette welding by 50% Reduction in man power by 15% Synchronized cell concept to complete quality job Types of Jobs Executed Orders Summary (Wt. given in MT) FINAN. YEAR AW GF DUCTS 2010-2011 239 861 365 - - - - 1,465 2011-2012 1,895 1,996 743 - - - - 4,634 2012-2013 1,540 2,148 408 284 58 67 - 4,505 2013-2014 - 77 - 240 - - 616 932 TOTAL 3,675 1,516 524 58 67 616 11,536 5,082 BELLOWS HAND RAIL WIND BOX MANHOLE TOTAL Jobs with our Esteemed Clients CLIENTS NAME Order (Wt in MT) BEVCON 1,934 BHEL 7,069 CETHAR 495 ENERGO 367 FLSMIDTH 2 ISCON 78 ISGEC 115 RJIL 616 SPCL 860 TOTAL 11,536 Order Summary of All Units (Wt in MT) # S.No. Year Pondy Unit Airtel, Ramboll, Customer Quipo, BSNL, Nortel, Infratel, Raipur UnitRaipur Unit-Other BHEL BHEL Bevcon, Cethar, IJT, ISCON, Energo Cumulative 1 2004-05 1,032 2 2005-06 11,205 11,205 3 2006-07 16,096 16,096 4 2007-08 27,205 27,205 5 2008-09 27,019 27,019 6 2009-10 18,107 18,107 7 2010-11 13,151 8 2011-12 11,879 9 2012-13 1,590 Total 127,283 1,032 679 3,812 292 4,783 787 14,617 826 16,518 136 2,017 1,748 133,816 Our Commitments Committed to manufacture and supply of fabricated structures with one mind set “GANGES ON TIME” and every time • Committed to Right quality which exceeds Customer expectations. • Committed to follow LEAN manufacturing to avoid non value added activities and wastes in fabrication process • Committed to Continual improvement of our Quality Management System through effective implementation, in order to achieve customer delight Committed to follow Kaizen principles to improve productivity in business processes and supply chains • Committed to follow TPM, TQM and JIT for shop floor and manufacturing activities Assess/ Reassess Evaluate Continuous Improvement Plan and Design Implement “GANGES ON TIME” 30 Plant Head- Mr Anil Mishra- 33 Years experience heavy engineering experience since 1980 was planning head at ANG Auto from 2009 to 2010 which manufactured all boiler support structures, Triveni Structural Ltd, form 1980 to 2009. Quality Head- Mr Sanjay Saytode- 8 years experience in Heavy engineering since 2005 was Senior Engineer at ANG Auto from which manufacture all boiler support structures also worked at Simplex Engg. & foundry Works, Bhilai which manufactured all boiler support structures & equipment. Welding Trainer- Mr Eti Suresh – 11 years experience as Welder Trainer at ABG ship yard from 2005 to 2010 also worked at Candid Merin, Singapore as Sr. Supervisor form 2001 to 2004, he is AWS QC-1 certified. NDT Personnel 1 NAME NDT LEVEL-II IN CERTIFICATE NO. SANJAY KUMAR SAYTODE 1. MPT NA/MPT/0900369 2. UT UT/BH/0807127 3. LPT 2 VIKAS KUMAR PANDEY 1. UT 2. LPT LP/BH/0901164 UT/BH/0908193 LP/BH/0908194 Achievements Mr. Vinay Goyal, Receiving "Award for Quality" from Mr. A.V. KrishnanExecutive Director, BHEL Certificate for Quality from BHEL Ganges Internationale Pvt. Ltd, Vidhan Sabha Road, Saddu, Raipur (CG) www.gangesintl.com 34