Reduction In Slide Label Mis-Identifications Due To Implementation

advertisement

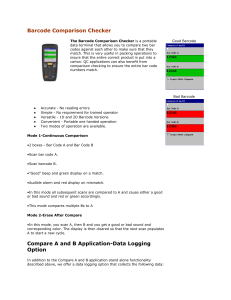

Gaurav Sharma, Bryan J Dangott, Anthony Piccoli Luke T Wiehagen, Susan M Kelly, William R Stewart Samuel A Yousem, Liron Pantanowitz, Anil V Parwani. Department of Pathology University of Pittsburgh Medical Center Pittsburgh, Pennsylvania, United States Email: sharmag@upmc.edu Background Barcoding in AP labs Identification Workflow Tracking UPMC histology bar-coding project has evolved from Pittsburgh Regional Healthcare Initiative (PRHI) PRHI Executive Summary (August 2004) : Moving towards one-by-one processing at UPMC Shadyside “Because the team would be using techniques adopted from the Toyota Production System (TPS), and because histology, the midpoint of the work, operated something like an assembly line, the decision was made to begin there. Eventually, the goal is to make the entire process—from the Gross Room to the pathologist’s interpretation—one continuous flow process.” Histology Gross Room Workflow-Pre Barcoding Implementation Received Accessioned Container Requisition Hand Labeled Coverslip Verify Slide Labels Printed Blocks processed Slide(s) made Slides sent to Pathologist Cassettes Hand Labeled Tissue Embedded Grossed & Cassettes Submitted Cassettes Verified Manual entry or retrieval of case # Histology Gross Room Workflow-Post Barcoding Implementation Received Accessioned Container Barcode Stained Cover-slip Verified Slide Labels Printed Blocks processed Slide(s) made Slides sent to Pathologist Case details Entered Grossed & Cassettes (Barcode) Tissue Embedded Cassettes Verified Technology Laboratory information system-CoPath version 3.2 with workflow and tracking system-CoPath Plus Advanced Barcoding and Tracking (Cerner DHT, Kansas City, MO) Barcode cassette printers-Shandon Microwriter (Thermo Scientific, Waltham, MA) and GDKV2-C (General Data Corporation, Cincinnati, OH) Thermal slide label printers-Cognitive Cxi (CognitiveTPG, Lincolnshire, IL) using chemical resistant adhesive labels StainerShield XT(General Data Corporation, Cincinnati) Barcode scanners-Symbol DS 6607 and 6707 (Motorola Corporation, Schaumburg, IL). Design 2 D Datamatrix Vendor: General Data Blocks Slides Barcode scanners: Accessioning area Gross Room Histology Room Pathologist Offices Barcode printers (cassettes): Gross Room Barcode printers (slides) : Histology Room *Order secondary stains or annotate blocks* Cassette Engraver Processor *VERIFY blocks post-embedding* Embedding *Track blocks pre/ post-processing* Microtomy *PRINT labels or queue slide engraving* Cassette File Label printer Label printer Staining Final distribution Case review & Sign out Slide File *Stain code id’ed by stain processor* *VERIFY slides prior to distribution* *OPEN specimen or validate against bar-coded report *ORDER recuts/stains 20 07 -0 20 3 07 -0 20 5 07 -0 20 7 07 -0 20 9 07 -1 20 1 08 -0 20 1 08 -0 20 3 08 -0 20 5 08 -0 20 7 08 -0 20 9 08 -1 20 1 09 -0 20 1 09 -0 20 3 09 -0 20 5 09 -0 20 7 09 -0 20 9 09 -1 20 1 10 -0 20 1 10 -0 20 3 10 -0 5 Slides/month Results Slide label mis-identification/SHY 10 Pre-implementation (2.5/m) Implementation (0.5 cases/m) -1 Month-Year Post-implementation (0.58 cases/m) 9 8 7 6 5 4 3 2 1 0 Defects Causes Pre-barcode Manual entry of case numbers Post-barcode Tissue curl (from preceding case) picked up Cytology blocks not barcoded Resolution (recent cases) Recently, issues are not related to manual case entry Personnel issues, not related to barcode technology Cytology blocks to be barcoded Results As a technology Complex Multi-step process integration Factor in LIS updates and compatibility Novel tracking solutions had to be designed Implementation Must be well planned with input from vendors Adequate resource and time must be committed Equipment procurement/installation takes time Downtime procedures must be written up Conclusions Anatomic pathology specimen identification systems such as 2D barcoding and associated tracking tools can help significantly reduce mislabeling errors in the pathology laboratory and thus improve patient safety. Other benefits Real time status tracking Containers, blocks, slides etc. Case can be tracked with better accuracy A tracking tool (Advanced Barcode & Tracking) was codeveloped with the vendor Digital Pathology workflow Barcode protocols can be extended to images for definite image and specimen identification http://www.neatorama.com/images/2005-11/zebra-barcode.jpg Thank you