Quality & Appeal

advertisement

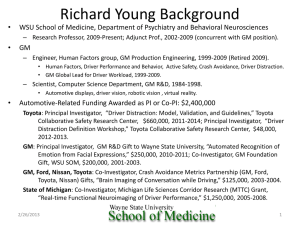

Powering Ideas ™ Trademark Contents Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Styron Automotive – Fast Facts Styron Automotive is a business within Styron that is committed to the Automotive industry’s thermoplastics needs. Styron Automotive is lead by Mr. Dagmar van Heur, VP Automotive, who has 20 years+ experience in the automotive business Styron Automotive has: – approx. 250 employees worldwide – an expected turnover of 1 billion USD by 2015 OEM and Tier customers are supported by dedicated resources, including: – an experienced R&D team, including a specialized CAE Engineering center – a global commercial team, focusing on the global needs of our customers, but dedicated to local implementation. HOME Automotive Plastics Supply Per Region Europe, Middle East, Africa PP compounds ABS 30% 46% PC ABS 24% Americas PP compounds ABS 37% 33 % North America: 24% South America: 19% 51% Asia Pacific 215,000 MT in 2012 PP compounds ABS 15% 46% PC ABS 30% 6% PC ABS 38% HOME Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Quality Our Credo: STYRON AUTOMOTIVE delivers best in class product quality and services to the automotive Tiers and OEMs. This will enable consistent quality appearance and create brand value for our customers. We take every quality message serious and welcome it as a chance to learn and improve to rise to the expectations of our customers. It is our commitment to respond to complaints meeting customer and project time lines. HOME Quality We guarantee the same quality and same specifications worldwide in compliance with ISO/TS 16949, offering you reliable and consistent solutions wherever you may need them. Styron Automotive demonstrates a continuous improvement quality vision, in line with the needs of our customers Robust supply is not just a notion, it is what we live. HOME Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Product Portfolio & Market Position PULSETM PC/ABS: Marketleader in Europe and North America – > 50% market share Strenghts of the new PULSETM GX family (launched in 2012): – Lower polycarbonate content than conventional PC/ABS products – Therefore providing lower density and lower weight – Outstanding high impact strength at low temperatures – Tailor-made heat distortion resistance MAGNUMTM ABS: Leading supplier in Europe and North America of Mass ABS Strengths: – a highly consistent, white base color, resulting in a combination of excellent processability and aesthetics, which make it suitable for self coloring. – Highheat ABS (> 50% market share) – Low and ultra low gloss product offering (MAGNUMTM SLG) – Ultra low emissions HOME Product Portfolio & Market Position INSPIRETM Polypropylene: – Customized polypropylene compounds product offering in Brazil with >25% market share – Specialised supplier of PP compounds in Europe and North America (3% overall market share, about 5% interior, 1% exterior) Strength: – Robust material quality and performance – High to very high scratch resistance – Product simplification, several products which have been accepted across the industry LGF PP systems, offering direct 20-40% LGF products, but also 60% LGF concentrate with neat PP for dilution – Very innovative application development as demonstrated during 2012 by • Clio tailgate, first ever full thermoplastic Tailgate design • SPE award for a Ford Fusion safety part HOME Product Portfolio & Market Position VELVEXTM Reinforced Elastomers Newly developed product offering Strength: – Offers an opportunity for premium surfaces, supporting the impression of luxury in vehicle interiors – For unpainted interior trim applications – For outstanding scratch resistance and parts with excellent haptic qualities – No whitening after scratch and reduced scratch visibility – Closes the gap between the need to balance both technical and aesthetic performance – and at affordable cost HOME Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Megatrends GLOBALITY QUALITY & APPEAL ENERGY EFFICIENCY HOME Megatrends The Automotive industry is influenced by several Megatrends, such as: Quality & Appeal Studies have shown that the interior is becoming a more and more important criteria for end-customers in their choice of vehicle. Styron automotive strives interior quality and appeal excellence, but also has a product offering supporting the sustainability of that quality and appearance HOME Megatrends The Automotive industry is influenced by several Megatrends, such as: Energy Efficiency Several governments are increasingly critical of the emissions and fuel efficiency levels of the current fleet of vehicles. The Obama government has a target of 54.5 mpg fleet fuel consumption by 2020, whereas the EU committee is expected to reduce the CO2 emission targets for the EU car fleet to 95 g/km and below in that same time frame. Styron is helping OEMs to reduce the weight of the vehicles and optimizing wind and tyre drag, which has a direct positive effect on fuel consumption and emissions HOME Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Globality We are committed to delivering consistent and reliable solutions worldwide At Styron Automotive, it is essential to maintain close relationship with our customers and meet the needs of our local and global clients. OEM platforms are becoming more and more global and will be produced in all target markets. At the same time, the OEMs need to be competitive within these local markets. Styron strives to have its main products locally available in global grades by 2014. Given the continuous expansion of OEMs and their increasing demands to ensure parts consistency for all of their car models across their global platforms, we make sure our innovative plastic solutions are not only allowing our customers to differentiate, but are also available worldwide. HOME Globality Styron Automotive Locations Worldwide Stade Terheuzen Auburn Hills, MI Netherlands USA Germany Paris Midland, MI USA Berwyn, IL France Clinton, TN USA USA Dyersburg, TN USA Germany Schwalbach Barcelona Horgen Switzerland Spain Tokyo Japan Hsinchu Mexico City Shanghai China Taiwan Mexico São Paulo Limão Brazil Brazil Global Operating Center Production Research & Development Commercial Office HOME Globality Core Automotive Locations Terheuzen, Netherlands Auburn Hills, USA Automotive Commercial Office Midland, USA Automotive Technical Service Customer Service Automotive R&D Application Development & Engineering Center Automotive Technical Service Schwalbach,Germany Automotive Commercial Office Customer Service Shanghai Asia Pacific Automotive Center Mexico City, Mexico Automotive Technical & Commercial Office Limão, Brazil Automotive Technical, Commercial & Customer Service HOME Globality Styron Automotive Team Worldwide Stade Germany Schwalbach Terheuzen Auburn Hills, MI Netherlands USA Midland, MI USA Berwyn, IL Dyersburg, TN Horgen France Clinton, TN USA USA USA Germany Paris Barcelona Switzerland Spain Tokyo Japan Hsinchu Mexico City Shanghai China Taiwan Mexico São Paulo Limão Brazil Brazil Production Research & Development Commercial Office HOME Globality Product families We aim to have all materials locally produced during the next 2 years Stade Germany Terheuzen Allyn’s Point, CT Schkopau Netherlands Tessenderlo USA Midland, MI Boehlen Belgium USA ABS PCABS PPcomp LGF Coloring ABS PCABS PPcomp LGF Germany Germany Zhangjiagang China Taiwan Hong Kong Merak Indonesia PCABS PPcomp Factory Coloring Hsinchu Tsing Yi PCABS PPcomp Coloring LGF*) Limão Brazil Plastics *) Partner Qualification HOME Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Energy Efficiency Supporting lighter, more fuel-efficient vehicles. Although the focus on reducing emissions and fuel consumption is through improving the efficiency of the engine, light-weighting can add to this quest: 100 kg car weight reduction leads to a further 5-7% fuel reduction Styron Automotive supports the OEMs by introducing innovative applications. An example is this 3 part lift-gate assembly of the New Renault Clio, which was developed by Styron Automotive together with Renault and offers more than 10% weight reduction vs. its steel alternative HOME Energy Efficiency Increased interest for reinforced plastics in Structural applications GX50 – Thickness [mm] GX50 – Displacement Contour Plot Thickness (Scalar value) Contour Plot Displacement (Mag) Analysis System 2.50 100% 2.32 89% 2.13 78% 1.95 67% Part wall thickness reduction 1.77 55% 1.58 44% – Through materials with improved flow 1.40 33% 1.22 22% 1.03 11% Interior Applications – Supporting new processing methods 0.85 0% Z Z Y Density reduction materials – New PULSETM PC/ABS products – Use of physical or chemical blowing agents X X Y GX50 – 1.8/2.5 mm – Thickness [mm] GX50 – 1.8/2.5 mm Displacement Contour Plot Thickness (Scalar value) Contour Plot Displacement (Mag) Analysis System Elektro-Vehicles Materials with improved Ignition Resistance 2.50 116% 2.32 103% 2.13 90% 1.95 77% 1.77 64% 1.58 51% 1.40 39% 1.22 25% 1.03 13% 0.85 0% Z Z X Y X Y HOME Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Contents Styron Automotive – Fast Facts Quality Product Portfolio & Market Position Megatrends Globality Energy Efficiency Quality & Appeal Quality and Appeal We continue to enhance the look and feel for automotive parts Not only the new car quality and appearance are important, most cars are re-sold at least once during their car life. A sustainable quality of the interior will lead to higher re-sale values and is therewith in the interest of the OEM for their branding and the end-customers alike Styron supports this trend with VELVEXTM, MAGNUMTM SLG, PULSETM GX 50 for unpainted application, INSPIRETM PP compounds (and BRANCOM PP in Brazil) Styron Automotive is able to offer costeffective solutions that fulfill customers expectations in quality and appeal. HOME Quality and Appeal Improved quality and appearance for the interior Reinforced by an increasing amount of small car model produced by premium OEM’s Leads to higher quality requirements: – Fit and finish – During and after use: Scratch and mar resistance – Anti-Static Lower gloss for materials with higher heat resistance Fits the trend towards less painted parts Specific products in ABS and PC/ABS available, also featuring: – High UV resistance – High hydrolitic stability Higher gloss for interior trim parts Piano black ABS and PC/ABS reinforced optical foils HOME Quality and Appeal VELVEXTM Reinforced Elastomers Performance comparison after 18N scratch test 4.5 dL after scratch Scratch Test Results VELVEXTM TF-TPO VELVEXTM Talc Filled TPO 4 3.5 glossy dL 3 2.5 2 1.5 1 0.5 0 TF 1500 Reference part VELVEX part HOME HOME “This information is considered accurate and reliable as of the date of this communication and is presented in good faith. Because use conditions and applicable laws may differ from one location to another and may change with time, the Customer is responsible for determining whether the information in this document is appropriate for the Customer’s use. Since Styron has no control over how this information may ultimately be used, all liability is expressly disclaimed and Styron assumes no obligation or liability therefore. No warranty, express or implied, is given nor is freedom from any patent owned by The Styron Corporation or others to be inferred.”