Detailed Design PPT

advertisement

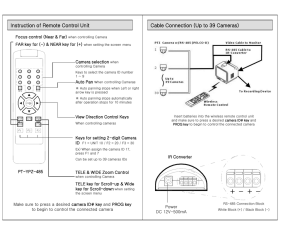

Advisor: Dr. Becker-Gomez Tim Southerton Matthew Morris Kevin Meehan Brian Grosso Lalit Tanwar Alex Reid RC Camera Car DDR 1 Background Problem Definition Stakeholders Review Major Purchase Camera and Video Transmission Total Budget Power Budget Weight Analysis Component Layout Component Updates Performance Data Differential Drive Speed Engineering Req.’s Review Dashboard Indicators RC Camera Car DDR Console Construction Car Bumper Rev 2 MBED Programming Simulink Interfacing Steering Wheel Modifications Dedicated Computer Car Electronics Plan Schematics Console Flow Chart Course Components Lab Topics System Functional Decomp. Risk Management MSD II Planning 2 Project Goal: Build a RC car platform controlled remotely with intuitive controls and visual feedback that can be expanded to demonstrate Controls to college students. The project needs to be captivating and able to demonstrate multidisciplinary engineering innovation at various RIT events this year and into the future. Deliverables: 1. 2. 3. 4. 5. 6. 7. 8. RC Car Platform with Cameras and Sensors Driving Station with Controller Equation of Motion of the System Characterizing Parameters of the System Source Code for Low Level Processing Interface for Student Coding Preliminary Differential Drive Code Supporting Documentation RC Camera Car SDR 3 Customer: Dr. Juan Cockburn Controls Professor, RIT, Computer Engineering (CE) Sponsors: RIT CE Department, Multidisciplinary Senior Design (MSD) Freescale Semiconductor RIT FMS (Chris Furnare and Jim Shuffield) RIT ME Department (Bill Finch) Event Attendees: Imagine RIT, Freescale Cup 2014 Various Campus Symposiums and Workshops MSD Team Future RIT MSD Teams / Prospective Students RC Camera Car DDR 4 Ready Made RC LLC – Ohio – US Custom 5.8 FPV Starter Package: $232.70 RMRC-420XV NTSC CCD Camera ImmersionRC 600mW 5.8GHz Video Transmitter Uno5800 5.8GHz Receiver Standard Whip Antennas 2 x RMRC 1100mAh Batteries LiPo Charger and Voltage Level Indicator Amazon: $37.26 RC Camera Car DDR 5 Total Budget 12-6-13 Min. Projected Remaining Expenses $141.40 Course Materials, Assorted Extras On Target: $505.25 Total to be Spent Long Lead Time Items Ordered at Minimum Cost Approximately $363.85 Spent Thus Far Approximately $1328.25 in Total Value of Parts Student Donated ~$170 Freescale Donation ~$600 Caster City Donation ~$60 FMS / Free Items ~$80 ME Dept. Donation - Free Computer, Table Surfaces ~$50 RC Camera Car DDR 6 Camera runtime estimated at ~4 hrs 2 LiPo Batteries coming for camera which can be one off one on charging Far exceeds specs RC Camera Car DDR Car runtime estimated at ~4 hrs Additional NiMH battery available from CE Department Far exceeds specs 7 DDR Weight Analysis Components weighed and values for those not purchased tabulated <10% More than 2013 RIT Freescale Cup Car 20% Less than when car tested for performance (batteries weight will be less on final product) Car will be able to move all the necessary components without issue RC Camera Car DDR 8 Scale CAD model made of car electronics layout to verify that everything will fit Significant room for expandability RC Camera Car DDR 9 Performance Testing Car tested with RC controls + Arduino taking encoder data and transmitting back to laptop through Xbee’s Car run with two RC batteries (high weight) and car easily made it over Freescale bump Gathered performance data that compared favorably with metrics Information gained on bumper functionality, drivability, and clearance RC Camera Car DDR 10 RC Camera Car DDR 11 Accelerometers unrealistic for linear speed measurement Linear speed of car to be determined by averaging left and right wheel speeds Used as reference for feedback loop Easily available data for Simulink Possible integration into console display RC Camera Car DDR 12 Detailed Engineering Requirements Preliminary Testing Results: 0 to Max Speed Max Speed to 0 Max Speed Max Range 2.8s 2.4s 10ft/s 141 ft Addressed Items: Dashboard Indicators Dedicated Computer for Project RC Camera Car DDR 13 Freescale automotive division MC9S12HY64 instrument cluster demo board donated for project Stand built for protection and viewing RC Camera Car DDR Movement! 14 Console updated with lower mounting height difference between chair and table base Changed to moving table toward user for safety Found better desk and base surface RC Camera Car DDR 15 Temporarily mounting casters and screen New casters to be expected near start of MSD II Possible seat belt for authenticity, time depending Possible seat plate with team information RC Camera Car DDR 16 New bumper design made with driving feedback (protection) Polyethylene foam cut using hot wire foam cutter RC Camera Car DDR 17 Freedom Board, Xbee, Accelerometer, MATLAB Testing MBED functionality with Xbee’s and MATLAB for KL25Z Freedom Board confirmed RC Camera Car DDR 18 Serial information can be directly imported / exported from Simulink model This will be integrated with Brian’s model to output motor speed signal Simple interface for students to program http://www.mathworks.com/help/releases/R20 13b/instrument/srcblkparam.gif RC Camera Car DDR 19 Access hatch added to allow for quicker electrical work and internal component mounting KL25Z board mounted inside and wires connected to board outputs for interfacing with board RC Camera Car DDR 20 Change of approach on console side to controller and Xbee’s communicating directly with computer Simulink running controls application on computer with serial in/out communication Need for dedicated computer for project to reduce program version issues and increase robustness of final deliverable RC Camera Car DDR 21 Using TLC Motor Shield on KL25Z Replacing pin headers on motor shield with through pin headers to access unused pins Attaching Xbee and encoder circuits using a perfboard shield on top of motor shield Use existing switches, potentiometers, LED’s, and servo outputs as necessary RC Camera Car DDR 22 RC Camera Car DDR 23 RC Camera Car DDR 24 RC Camera Car DDR 25 RC Camera Car DDR 26 RC Camera Car DDR 27 RC Camera Car DDR 28 RC Camera Car DDR 29 Freescale Cup Tarp 15’4” x 20’4” Stored in MSD Area Used on Floor with Tables Moved Course Edging and Obstacles TBD Budget Depending ~$60 Available Fix Freescale Bump Storage Limited RC Camera Car DDR 30 1) Physics Theory - Brian's Differential Drive Model Assumptions and Turning Radius / Speed Formulas 2) Controls Application Wheel Speed Averaging and PI Control 3) Console Microcontroller Information Microcontroller / Electronics Console Controls and Outputs 4) Chassis Construction and Information Car Steering Servo and Drive Motors Stats - Wheelbase, Track, Weight, Time Constants Battery and Power Management Assembly Instructions RC Camera Car DDR 31 5) Car Microcontroller Information 6) Wireless Communication Information Readings Data into Simulink Outputting Data from Simulink 8) Testing Xbee Distance Stats and Info Camera Distance Stats and Info X-CTU, Updating, and Bricking Issues Using Xbee's with MBED 7) Simulink Interfacing Microcontroller / Electronics Car Inputs and Outputs Uploading Code Implementing Model Changes Verifying Results Sample Code and Demo 9) FAQs and Troubleshooting RC Camera Car DDR 32 Successfully Completed Addressed with POC MSD II RC Camera Car DDR 33 Risk Management RC Camera Car DDR 34 Test Plan Test Chassis and Console Verify Physical Component Limitations Test Wireless Communications Functioning Distance Record Data at Imagine RIT User Feedback – Likert Scale Statistical Driving Data Finalized Project Deliverables Total Cost, Event Entries, Component Specs, Included System Functionality RC Camera Car DDR 35 Wheel Speed Sampling Solution and Testing Optical Gate Speed Testing KL25Z Xbee / Motor Controller Integration Controls Application Software Integration Table Surfacing and Component Mounting Course Design Component Mounts Aesthetics RC Camera Car DDR 36 MSD II Planning 36 items identified for MSD II Week 5 Demo Working Car using Console Drive Controls Week 8 Demo Working Controls Applications Week 12 Demo Working Course and Car Still plenty of work to be done RC Camera Car DDR 37 P14226 EDGE Site RC Camera Car DDR 38