NEBB Procedural Standards: Reports - Northern California

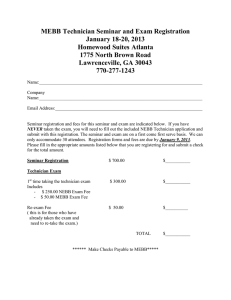

advertisement

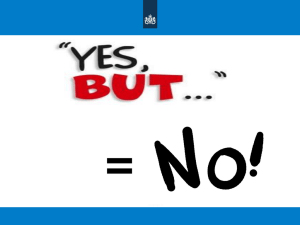

NEBB Procedural Standards: Reports Jason Huffman, Pacific Test and Balance, Inc. - TCC By PTB Agenda Are we meeting the NEBB criteria or exceeding it? Item 1 Item 2 Item 3 Item 4 Item 5 Item 6 Discussion Item One – Procedural Standards 2005 – 7th Edition 8th Edition possibly coming in 2014? Discussion Item Two – Substance, Minimum Forms Are all “Shall’s” being included? Discussion Item Three – Certification Page All requirements met? Wet vs. digital signature – Who can apply your signature? Discussion Item Four – Project Summary Does the summary clearly outline the project results needed by decision makers? Discussion Item Five – TOC, Keyed Drawings Clear and Concise? Discussion Item Six – Recertification Review What is the process of Re-Certification Review PROCEDURAL STANDARDS 2005 – 7th EDITION Are All Shall’s Being Met? • This bar set by NEBB is a minimum amount of effort for TAB Contractors. Minimum Content? Shall, Should & May • Is more required to satisfy the clients needs? • Examples of effort that is above and beyond “shall”: • Static profile on drawing of equipment. • Pictures of deficiencies or hard to understand scenarios. • Including should and may items. • What is the value of more? • Are you selling the next job with this job? • Are you supporting the NEBB Organization with quality? • Can one report bring down the reputation of NEBB? REPORT CERTIFICATION This data may be included on the report title page or separate certification page. SHALL DATA • • • • • • • Project Name Certifying NEBB CP Name Firm Name Certification Number Expiration Date Certifying NEBB CP Signature • Signed (wet) & Dated SIGNATURE STAMPS VS. DIGITAL S.S. • No confirmation on new rules concerning allowance for Digital Signature Stamps. • Ink Signature Stamp • Digital Signature Stamp (EXACT VERBIAGE) “THE DATA PRESENTED IN THIS REPORT IS A RECORD OF SYSTEM MEASUREMENTS AND FINAL ADJUSTMENTS THAT HAVE BEEN OBTAINED IN ACCORDANCE WITH THE CURRENT EDITION OF THE NEBB PROCEDURAL STANDARDS FOR TESTING, ADJUSTING, AND BALANCING OF ENVIRONMENTAL SYSTEMS. ANY VARIANCES FROM DESIGN QUANTITIES, WHICH EXCEED NEBB TOLERANCES, ARE NOTED IN THE TEST-ADJUST-BALANCE REPORT PROJECT SUMMARY.” PROJECT SUMMARY / REMARKS What was the scope of work and what was the conclusion? • A narrative description of system setup conditions established prior to testing adjusting and balancing. • A listing of deficiencies in the summary and identifies the appropriate pages in the report. • The rational for posturing the system and the steps taken to achieve the desired setup. • These items exceed NEBB or Contract tolerance or any other items that require discussion / explanation. • The CP’s job is to assess the validity and accuracy of all summary items. TABLE OF CONTENTS AND ALL PAGES Organized for the reviewer? Company specific. • Serves as a guide to the overall format and organization of the report. • SHALL – Page numbers of the system and component information in the report. • A road map to all data but also a direct route to items addressed in the project summary. • All tested items included in the report SHALL be clearly identified with a unique designation. • Each test form SHALL include the name of the responsible technician /CP who reported the information and the time period the data was collected. INSTRUMENT CALIBRATIONS & ABBREVIATIONS If it’s in the report, it has to be listed and covered. • All date ranges which are listed on every test page, need to be covered by date ranges on the Instrument Calibration Page. • • • If the report covers a range over a year or retests are done at a later date and addendums are produced, then include 2 years of calibrations where applicable. Equipment listed must be the instruments that will be used to verify the data in the report. All abbreviations used in the report anywhere must be listed, test data or comments. • • If the project is Metric then Metric Abbreviations must be included. Quality assurance may be necessary for repeat definitions i.e. – Heat Pump or Horsepower, which is HP? NEBB COMPANY RE-CERTIFICATION What is required every two years? What to expect? How to help? • Steps for making the process simple • Label all files properly. • Organize equipment with certifications pages and pictures in order with the C-1 form equipment list. • Fill-out forms digitally if at all possible. • Turn-in complete reports that give the best example of multiple forms (no partial reports). • If you cannot give a good variety of forms in two reports (recommended amount) turn in three or talk to TCC if your company has a limited work scope. • The company is providing proof to the Technical Committee that NEBB requirements are met on all projects. NEBB COMPANY RE-CERTIFICATION What is the process? • The NEBB company files are submitted to the Chapter Coordinator who provides a cursory review of completeness prior to submitting to Technical Committee for review . • The Technical Committee will gather on scheduled days and groups of 2 CP’s will be formed with each representing separate companies. • The Chapter Coordinator will assign each pair of CP’s two Companies and deliver their submitted files for review. • Each CP will review one company’s documentation for completeness and accuracy according to the C-1 Form,(Instrumentation) and TAB Report Review Form. • Upon completion the CP’s will exchange company document packages and separately review independent of “first findings”. • The CP’s then review findings together and bring results to the TCC and Chapter Coordinator to discuss the next steps. NEBB COMPANY RE-CERTIFICATION Pass or…….? • If the company satisfactorily passes all re-certification requirements: • Congratulations, see you in 2 years! • If there are marginal issues the company will be advised to integrate changes into their forms or make changes with instrumentation issues as soon as feasible (at the companies discretion if not a NEBB minimum criteria issue) and incorporate in the next review 2 years down the road. • The Chapter Coordinator will follow up with National to process and procure all new NEBB docs for the Company. • Consider volunteering for the Technical Committee. NEBB COMPANY RE-CERTIFICATION If at first you don’t succeed…….. • If the company does not satisfactorily pass all recertification requirements: • The C-1 and TAB report forms will be returned with all marginal and inadequate line items highlighted along with clear and concise, typed comments from the reviewing CP team in order for corrections to be made. • All discussions and / or questions requesting clarification need to occur between the TCC and the certifying CP representing NEBB company through the Chapter Coordinator. • The Chapter Coordinator will follow up and receive all revised documentation for additional review. • Final review by TCC and 2nd failure will go to the board for review and comment (possibly on to National). NEBB COMPANY RE-CERTIFICATION What can you do to help? • Consider Volunteering: • NorCal/Hawaii NEBB has 27 certified firms and 41 CP’s. • Around half of the companies recertify each year. • If each group of 2 CP’s review 2 companies each review day per year the TCC will need the support of 12 to 14 CP’s each review session. • The sessions can take 4-6 hours and can be a great time to interact and get to know your peers in the industry. • Any issues with the process can be aired and resolved much easier when participating in the process rather than complaining from the outside in. • It will take hard work from everyone to continue to grow NEBB into a formidable market competitor. (OR DOMINATOR!) What does NEBB offer our clients? Integrity Consistency Honesty Value Results Through hard work and dedication we can make NEBB the Premier TAB Organization for Hawaii and California!