Georgia Transmission Corporation

advertisement

Georgia Transmission Corporation (GTC)

Reliability Initiatives

GSU Presentation

September 2012

Douglas O. Maddox

• Manager – System Reliability

• Started as distribution & lighting engineer

• Manages a department of six engineers and

coop student

• (1) Power Quality / Digital Fault Recorder (DFR)

• (2) Clearance Mitigation staff

• (1) Outage investigator

• (1) Benchmarking and results reporting

• (1) Trending and programs

GTC Background

• Created from Oglethorpe Power Corporation

(OPC) reorganization in 1997

• New smaller Board of Directors with outside

directors

• Reliability is job one

• Keep improving until we say stop

• Continuous feedback on reliability

• Measure, report, and benchmark data

• Reduce frequency and duration of outages

This Presentation

• Illustrates how GTC reliability improvement is

built upon the technology of remote sensing,

monitoring, and control equipment

• Explains how GTC fits in to the overall utility

structure in Georgia

• IS NOT about preventing widespread

blackouts or new FERC/ NERC ERO

standards

Functions and types of

Georgia’s electric utilities

Georgia Utilities

Function

Generation

Function

Transmission

Georgia

Transmission

Function

Distribution

Cooperatives - 39

Oglethorpe

Power

Individual

EMCs

Municipals ~ 48

MEAGPower MEAGPower

Individual Cities

Investor Owned Georgia Power

GPC

GPC

GPC

Cooperatives - 3

TVA

TVA

TVA

Georgia EMC Service Areas

Remote Sensing Equipment

• First generation of sensors was end-user notification –

power problem or outage

• Equipment had no remote monitoring or control

• Relays were sensors but had no remote status or control

• Fuses and reclosers were down line sensors – no remote

status

• Outage notification via postcard, letter, phone call, visit,

etc.

• SCADA – supervisory control and data acquisition

• AMI – automated metering infrastructure

• Outage management systems - call in and tie to

Geographic Information Systems (GIS)

• Facebook, twitter, web sites

Power Circuit Breakers

Gas

Oil

Vacuum

Electromechanical Relays

Fuses (Southern States)

Recloser (Joslyn)

Meters

Electromechanical

Meter

AMI Meter

SCADA

RTU

Control Panel

Remote sensors - continued

• Electronic relays and Digital Fault Recorders

(DFRs)

• Fault indicators

• Fault Analysis and Lightning Location (FALLS)

lightning data & weather data

• Phasor measurement units (PMUs)

• Line loading and monitoring

• Substation monitors

• Telecommunications

1.

2.

3.

Phone lines

Satellite

Radio signals

DFR (USI)

SEL Relays

SEL-551

SEL-587

SEL-351S

PMU (SEL)

SEL-351A (With

PMU)

Line Loading Device (GridSense)

Substation Transformer Monitor (GridSense)

Fault Indicator (PDP)

FALLS Lightning Study Map

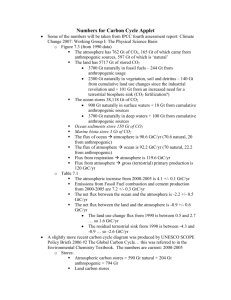

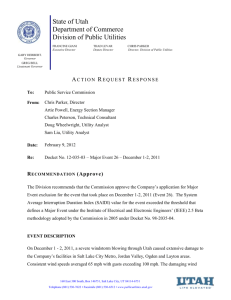

SAIDI Trend

35

Minutes Of Outage Time Per Customer

Yearly SAIDI

30

5 Year Average

Trend (5 Yr Avg)

25

23.17

GOOD

19.41

20

17.29

15

15.61

15.06

13.20

13.64

11.77

10

10.15

11.37

10.57 10.26

9.490

7.506

5

0

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

MAIFI

• One minute definition of sustained outage vs.

momentary outage is < one minute

• Lightning normalized (Georgia Integrated

Transmission System {ITS} standard)

• Found our ITS lines did not live up to stated Basic

Insulation Level (BIL) levels of protection vs. stroke

magnitude (older approach of 115 kV survives 30 kA

strike)

• Electric Power Research Institute (EPRI) T- Flash

program

• GTC standard 115 kV t/l design would have 3

momentary per year

Wins and Losses

• Results vary based on philosophy & location

• Great results Metal Oxide Varistors (MOVs) for

Homeland –Macedonia Primary (3 per structure)

from 8 to <1 momentary outage per year – only

strikes >100 kA flashed the line

• Terrible results for Douglas – Stump Creek

(Black) – distribution pattern of 3-1-1-1 did not

work, nor does 3-0-0 work

• Early fault indicator success – then false alarms

• Special 115 kV FI failed lab and field tests

T/L Arresters

Standard GTC 115 MOV approach

• Most structures are single poles

• Most structures have vertically mounted

phases

• T-Flash predicts “O” outages per year with 3

MOV per pole

• T- Flash predicts 0.16 outages per year with 2

MOV per pole

• GTC generally will save one MOV per pole to

stretch MOV funds

• Installation Pattern is top and bottom phase

Early Benchmarking

• 2003 trip to Florida Power and Light (FPL) for

Georgia Power, GTC, and our control centers

• FPL = 4 min SAIDI

• GTC = 15 min SAIDI

Differences

Looped lines – two way feeds

Redundant transformers

Intelligent fault detection and location

Sustained Outage Programs

• GTC study found 75% of SAIDI is switching &

restoring good loads; 25% is restoration

• Completed motorizing substation line switches

• Completed grounding switch replacements

• Nearly completed converting GTC’s pole

mounted manually operated switches to remote

control

• Extensive DFR upgrades, installations, & minis

• Replace obsolete switches

• Replace Silicon Carbide lightning arresters

Sustained Outage (continued)

•

•

•

•

•

Split long circuits

Modernize relaying (SEL)

Replace older breakers

Replace older transformers

Add reliability criteria to alternative selection

for capacity and voltage solving solutions

• Normally Open Point analysis

• Clearance mitigation efforts

Unfinished Sustained Outage Programs

•

•

•

•

•

•

•

•

•

•

ITS grounding switches to be replaced

Convert pole switches from manual to remote control

One directional fault indicators to be installed

Bidirectional fault indicators – testing phase

Replacements for old technology arresters, first

generation MOVs

Replace older, obsolete switches

On line transformer monitoring

Carrier relaying, tuners, traps

Real time DTF from DFR and SELs

Supporting GPC (ITS) 46 kV enhancement program

Clearance Mitigation

• 2003 time frame

• 25% of SAIDI and SAIFI under abnormal

conditions - clearances

• Both construction & maintenance

• Extended clearances

• Too many clearances

• Local equipment not in good condition

Clearance Mitigation (continued)

•

•

•

•

•

•

•

Combine maintenance work with construction

Combine line, sub, and metering work

Combine ITS and EMC work

Send report to EMCs daily

Minimize abnormal time & mobile time

Check lines and subs before going abnormal

Contingency plans

Digital Fault Recorders (DFRs)

• Replaced old Rochester Brand Units

• New USI brand units are Sequence of Events (SOE) &

DFR combination units, windows based, with data

accumulator able to be connected to home office server

• New APP brand units initially bought for smaller subs

and less capacity

• Allow GPC access to server & emails

• Populate real time distance to fault data into SCADA

• Go beyond minimal federally required locations

• Tie DFRs to FALLS data server

Relay Data Server

•

•

•

•

GTC hosted server similar to DFRs

Allows access to relay data

Cyber Security considerations

Does send emails

Power Quality Program

•

•

•

•

•

•

•

Investigate transmission problems

Assist EMC customers with investigations

Temporary meters

Permanent meters

PQ data server – GTC and EMC access

Consultant on standby

AMI systems susceptible to PQ issues

Power Quality Meters

Temporary

Permanent

MAIFI Improvements

• Overhead Ground Wire (OHGW) is installed

on virtually all lines serving GTC loads

• Different workshops on lightning and

grounding

• T/L MOVs

• FALLS acquisition

• ITS policy

FALLS

•

•

•

•

•

•

•

Obtained our own subscription

Review momentary outages down to 46 level

Send reports to EMC

Keep up with YTD results

Keep up with MOV effectiveness

Use in T-Flash

Use for MOV pattern selection

Remote Sensor Issues

•

•

•

•

•

•

Cost

Reliability

Ability to communicate

Battery life

Telecom path availability, capacity, and cost

Ability to install and maintain on energized

lines

Your Questions and comments?