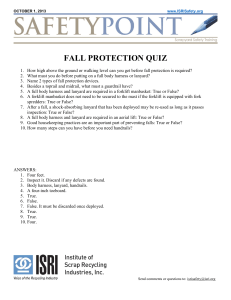

Fall Protection

Your life depends on it

Understand the purpose for fall protection

Identify fall protection locations

Understand and be familiar with how to use fall protection equipment

Understand employee’s responsibilities

Understand the regulations

Answer questions

Practice proficiency

Purpose of Fall Protection

Training is a part of this process

Protection at WBI Holdings may include:

◦ Guardrails with toeboards,

◦ Handrails

◦ Personal fall arrest systems

Anchor points

Full body harness

Restraint system

Shock absorbing lanyard

Fall limiter lanyard

Retractable lifeline

Rope grabs with vertical lifeline

Connectors

◦ Engineered horizontal lifelines

Flat and sloped roof locations when within 6 feet of the edge

Exterior and interior equipment, equipment or working platforms, catwalks, antennas/towers etc.

Exterior and interior fixed ladders above 20 feet

Open excavations or pits

Required use of articulating man lifts

When leaning outside the vertical rails of ladders and when performing work where 3 points of contact can’t be maintained

Scaffolding erection

Whenever there is a fall hazard above 6 feet or more

Guardrails may be required on stairways (4 or more steps) and walkways over 38 inches (4 feet)

Engineering controls

◦ Can the task be done remotely?

◦ Could it be redesigned?

◦ Engineered systems can be designed with 2 to 1 safety factor

Fall prevention system

◦ Guardrails (4 or more stairs and above 38 inches/4 ft)

Open walkways

Open pits

Open wall openings

Stairways (don’t forget the handrails)

Work platforms

◦ Restraint System

Harness attached to a line or lanyard

Line or lanyard attached to anchor point

Prevents fall beyond edge of working surface

Feasible Controls Types of controls

Fall Arrest System

◦ Full body harness

◦ Lanyard or self retracting lifeline

◦ Anchor point

5000 pound anchor point for free fall situations or

◦ not part of an engineered fall arrest system

Engineered horizontal lifelines can have a safety factor of 2 to 1

◦ 350 pound person and equipment = 450 pounds

◦ Anchor points need to hold 900 pounds

Self Retracting Life Lines – not part of an engineered system

◦ Engage within 2 ft – 3,000 pound

◦ Engage at or above 2 ft – 5,000 pound anchor

4 ft

3.5

1 ft

5 ft

3 ft

Total Estimated

Fall distance

16.5 ft

Know your distance! Don’t forget your connectors

2 ft

3 1/2 ft *

1 ft

5 ft

3 ft

14’ 1/2

Know your distance! Remember to add your connectors.

* 39 inches is required by code probable stop is 2 to 6 inches

Will the PPE keep you from falling a great distance?

Will the PPE keep you from hitting equipment?

Will the PPE lessen the damage or injury?

Consider what the PPE will do – stabilize, prevent injury, prevent death

Permanent and Temporary solutions

◦ Designed by an engineer

◦ Installed and used as designed

Have to know how many workers are allowed

Have to understand the tension on the line

Work as directly under the anchor point as possible to prevent swing back

Even with a retractable life line – consider the swing should you fall

When using the crane trolley remember to pull it so it is right above you

Think it out Before you snap it in

Examine and verify the nylon webbing to ensure there are no burn marks, or torn, frayed, broken fibers, pulled stitches or frayed edges

Examine D-ring for excessive wear, pits deterioration or cracks

Verify the buckles are not deformed, cracked and operate correctly – and easily

Grommets (if present) must be secure and not deformed

Rivets must be tight and not deformed

Tongue/straps should not have excessive wear

Harness Front and Back

Six steps to save your life http://www.millerfallprotection.com/fa ll-protection-products/videos/howto-put-on-a-harness-six-easy-stepsthat-could-save-your-life-2

Check for cuts, burns, abrasions, kinks, knots, broken stitches, and excessive wear

Inspect snaphooks for hook, locks and eye distortion

Check carabiner for excessive wear, distortion, and lock operation

All locking mechanisms must seat and lock properly and prevent hook from opening

Visually inspect shock absorber for signs of damage – look closely where it attaches to the lanyard

Verify points where lanyard attaches to the snaphook is free of defects

Lanyards and Shock Absorbing Lanyards

Inspect for hook and eye distortions

Verify there are no cracks, pitted surfaces or eye distortions

Ensure the keeper latch is not bent, distorted or obstructed and seats within the nose without binding

Ensure the spring mechanism closes the latch securely and locks properly

Inspect for integrity and attachment to solid surface

Snaphooks/Carabineers

Tie-off adaptors/Anchorages

Visually inspect to ensure no physical damage to the body of the unit

Ensure all back nuts or rivets are tight

Ensure the entire length of strap is free of any cuts, burns, abrasions, kinks, knots, broken stitches, or excessive wear and it retracts freely

Test unit to ensure it locks correctly with a sharp pull on the lanyard

Self Retracting Lanyards

Articulating Manlift

Horizontal Lifelines – line and anchors

Guardrails

Conduct

◦ Visual inspection for structural integrity

◦ Follow manufacturer’s recommendations

Other

Never store personal fall arrest equipment in the bottom of a tool box, on the ground, or exposed to the elements

Equipment should be hung up to retain its shape

Hanging equipment in a compressor building, warehouse, or locker is acceptable

Your life

Equipment should be kept relatively clean

◦ Clean with a mild soap and water

◦ Hang to dry

Equipment should not be stored near corrosives, excessive heat, chemicals, moisture or sunlight

Is on the line

Means of getting the person down or up depending on the space and the work

◦ Rope to bring down employee at 3 ft per second decent (Rescumatic or Rollgliss systems)

◦ Self rescue or assisted rescue

Use of Relief Step Safety

Device

Fall protection is both Up and down situations

Documented inspection required annually for all equipment

◦ Documented monthly inspection required for selfretracting lanyards

Annual training required

Harnesses, lanyards, snaphooks, carabineers, tie-off adaptors and anchorages must be destroyed if involved in a fall

Self-retracting lanyards must be inspected after a fall

◦ Manufacturer’s may have additional servicing and maintenance requirements – consult the user’s manual

Recognizing fall hazards

◦ General overview of fall protection

◦ Identify fall hazards at company facilities and work areas

Controlling fall hazards

◦ General overview of equipment

◦ Means of control at our facilities

◦ Ensuring co-workers and contractors control fall hazards

◦ Inspection and maintenance of equipment

◦ Installation of equipment

◦ Use of equipment

◦ Employee responsibilities

Review of Company policy

Hands on performance observation

Go to a location where a harness, lanyard, anchor points are needed for fall protection

Determine what equipment is necessary

Inspect equipment

Determine anchor points

Prepare to perform a climb

Discuss the rescue plan should a fall occur

Don equipment and perform a climb

After all the class has performed a climb consider a rescue operation