CLEAN MILK PRODUCTION (CMP)

advertisement

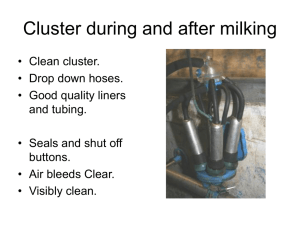

CLEAN MILK PRODUCTION (CMP) Dr. P. Vijayakumar CONCEPT OF CMP “Clean milk” – milk drawn from the udder of healthy animals, which is collected in clean, dry milking pail and free from extraneous matter like dirt, dust, flies, hay, manure etc.” Clean milk has a normal flavour with low bacterial count and is safe for human consumption. CONCEPT OF CMP Milk from udder – normally sterile Contains protein, lipid, lactose, minerals etc. Ideal medium for rapid proliferation of harmful micro-organism Needs to be protected from all possible sources of contamination Employment of hygienic practice at the time of milking – important CMP – beneficial to both producers and consumers Safe for human consumption Better keeping quality High commercial value Protection against diseases like typhoid, dysentry, diptheria, septic sore throat etc. Helps to produce good quality dairy products Transportation over long distances SIGNIFICANCE OF CMP Milk production stagnant between 1947 and 1970 Annual milk production increased to 112 million MT (2010-11) from 17 million MT (1950-51) Growth rate – 5.5 % per annum Projected milk production – 200-250 million MT by 2020 India’s global participation in milk trade – negligible Exports of milk and milk products very low FACTORS AFFECTING CMP Milk – source of protein and calcium Milk – most easily perishable and contaminated commodity Milk should be stored/chilled immediately after milking Hygienic practice from milking to factory Poor sanitation Poor storage High Bacterial Count Improper Handling Infection/Diseases Causes of high bacterial load in milk Soil Environment Water Feed and Fodder Concentrate, Fodder, Hay, Silage Drinking Water Milker’s Hygiene Animal Preparing of animal for milking Milk Milking Pail Bulk Tank Chilling of Milk Retail/Consumer Milk Tanks Milk Processing Plant Source of contamination of milk Internal factors External factors Udder infection – Mastitis Foremilk – contains large no. of bacteria Cow/animal’s body Udder and teats Milker – hygiene and habits Method of milking Milking Utensils Milk Storage utensils Feed and water Milking environment Contamination corrected at various levels Animal management Hygiene of milking equipments and utensils Milker and milking practices During storage and transport Personal hygiene MEASURES OF CMP The following measures should be taken care for the production of clean milk: 1. Animal Management at farm level Feeding Housing Animal Health 2.Cleanliness of Milking equipments 3. Hygienic milking practices 4. Cooling ANIMAL MANAGEMENT Milk from healthy udder – relatively free from harmful bacteria High bacterial count reduces the keeping quality of milk Animal management involves feeding, housing and health the FEEDING Balanced feed with appropriate quantities of green fodder straw and concentrates having essential nutrients and minerals is important Feed ingredients should be stored in moisturefree conditions Feed and fodder should be free from industrial and environmental contaminants, pesticides, insecticides, fungicides, fumigants, pathogenic agents, aflatoxins as well as heavy metals FEEDING Good quality straw and supply of adequate minerals and vitamins Feeding should be made one hour before milking During milking, non-dusty concentrate can be provided to keep animals busy Silage and wet crop residues should not be fed at milking place as it may impart foul odour to the milk HOUSING Animal shed - main sources of contamination Protects animals against micro-organisms, people, wind, rain, heat etc. Mud, urine, faeces and feed residues should be regularly removed from the shed Shed should have proper drainage, sufficient ventilation and lighting In very wet areas, slaked lime – used for drying Sufficient water facility should be available for drinking as well as washing the shed and animal HOUSING Shed : well-roofed, well ventilated, dry and comfortable with adequate elevation Appropriate arrangement for disposal of animal waste (manure pit or biogas plant) and left over feed & fodder Protection from flies and insect which are potential sources of contamination Piggery and poultry farming should be avoided near the animal premises ANIMAL HEALTH Pre-requisite for CMP – healthy herd Routine examination of cattle for diseases like TB, Brucellosis etc. Diseased animals should be kept separate Sanitary precautions to prevent and control diseases should be adopted Using inducer drugs should be avoided Check for udder wounds and mastitis. Vaccination of animals against FMD, Anthrax, etc. should be done regularly CLEANLINESS OF MILKING EQUIPMENTS AND UTENSILS Milking equipments : Milking pails, milking machine, milk cans, milk pipeline recorder, bulk, strainer, chiller, Bulk tank and storage tank etc. Residual milk in utensil – growth of microorganisms Proper cleaning removes germs and dirt CLEANLINESS OF MILKING EQUIPMENTS AND UTENSILS Milk vessels should be cleaned before and after each milking – rendering bacteria-free Detergents/chemicals used for cleaning should be non-injurious, non-toxic to health like Teepol Use of ash or mud not recommended Cleaned and sanitized vessels should be kept in inverted position Milking pail - dome shaped top should be used Open buckets should not be used HYGIENIC MILKING Key factors : Hygienic condition of storage and transport equipments and storage temperature Some organism may enter milk during hand milking and machine milking In addition, personal hygiene of the worker are important Hygienic practices during milking contribute to produce safe and suitable milk Floor sweeping just before milking should be avoided Milker’s Hygiene Free from communicable diseases Should wear clean clothes, nails trimmed Should neither eat or spit anything Before milking, milker should clean his hands with soap, potable water and then wipe with clean cloth or towel Clean the udder and teats with luke warm water and wipe with clean cloth or towel The fore stripping should be collected in separate utensil/cup and should be discarded to avoid flies and insects After milking, teat should be dipped in antiseptic solution to minimise risk of infection Wet milking (moistening hand in milk or water or oil) is not recommended Milking should be completed within 6-8 mins Milk should be strained using a clean cloth or a strainer. The cloth should be washed and dried daily COOLING Advantage of producing clean milk is lost if post milking handling is not carefully done To preserve the keeping quality of milk, it should be cooled as soon as possible to a temp. below 5°C in a refrigerator The sooner the milk is cooled after removal, the better is the quality Bacterial growth is retarded by cooling the milk within 2 hours of milking Delivery of milk to the factory or consumers should be as frequent as possible