Overfill Prevention - Port Compliance.org

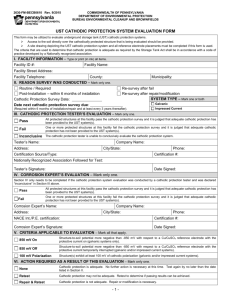

advertisement

Spill and Overfill Prevention General Requirements • Must have a spill bucket to prevent small spills during delivery, • Must have an overfill prevention device to prevent a large overfill, • Must prepare for and monitor deliveries to prevent overfilling in the first place, and • Must cleanup overfills and report large ones. The equipment alone will not prevent an overfill. Someone must be paying attention before, during and after the delivery. Overfill Exemption Not required on UST systems like waste oil tanks that receive less than 25 gallons at a time. Spill Buckets Should Be • Compatible with petroleum. • Able to keep out water. • Designed to catch small amounts of fuel. • Properly ID’ed. • Routinely cleaned out. • Secure. • Liquid tight. (Graphic courtesy of PEI) Which one is the spill bucket? Check the Drain Plug Product ID RED BLUE WHITE Make sure the colors match the actual product type. RED BLUE WHITE ORANGE Used Oil U Product ID Make sure the ID tags match the actual product type. Spill Buckets: What’s Wrong Here? Spill Bucket Problems • • • • • • • Cracked lids, bad seals. Compatibility with petroleum. Integrity of bucket not tested. Holes, cracks, wear. Drain plug sticks. Full of debris, water, sorbents. Surface damage. Overfill Prevention Overfill Prevention Options • Automatic shut-off device (at 95% full) • Ball float valve (at 95% full) • High-level alarm (at 90% full) (Graphic courtesy of PEI) Automatic Shut-Off Device Automatic Shut-Off Device • Don’t ever store your stick in the drop tube. • Can cause an overfill. • Can damage overfill device. Ball Float Valve • Located in vent pipe or vapor recovery pipe. • Cage can rusting out, ball floats away. • Incompatible with – Pressurized deliveries, – Suction piping with air eliminators, – Remote fills, – Coaxial Stage I VR. Ball Float Valve Open the extractor fitting Find the ball Ball Float Considerations • In 2005, Petroleum Equipment Institute began advising against using ball float valves for new installations. (RP-100). • Consider replacing them. Overfill Alarm • Set to alarm when 90% full. • Requires driver, not the operator, be alerted. • Tied into tank gauge or stand-alone alarm. • Common settings: – 90% High – 95% High-High – 100% Max Overfill Alarm Is it where the driver can see or hear it? Overfill Alarm Problems • Alarm not where driver can see or hear it. • Driver desensitized to meaning of alarm. • Fuel flowing over 300 gallons/minute. Alarm doesn’t stop anything. • Operator doesn’t hear it or know what it means. • Operator doesn’t know how to respond. • Operators tend to ignore or silence them. Monitoring Owner or Operator: • Measure the fuel level immediately before each delivery to make sure there is enough room in the tank. • Monitor the entire fuel transfer. • Report and cleanup all overfills. Careful Preparation Overfill in Biloxi, MS, 1998 UST Employee Training Training Employees • New Federal law will eventually require training for UST facility employees. Owner’s responsibility to train. • Training expectations not decided yet. It’s OK Sir. I ‘m a TRAINED PROFESSIONAL! What attendants and clerks should know • Basic parts of the system. • Emergency shut-down procedures. • Preventing overfills during deliveries. • Who to call if there is a problem. Corrosion Protection Overview • General requirements • Equipment • Operation and maintenance • Testing • Problems • Record keeping General Requirements • Tank and piping must be protected from corrosion. • Includes portions of UST system routinely containing product. – Yes: tank, product piping. – No: vent and fill piping. • Three ways to meet this requirement: – Non-metal materials, – Galvanic cathodic protection, – Impressed current cathodic protection and/or internal epoxy liner. General Requirements 1. Non-metal tank/pipe material – Tank: Fiberglass, Fiberglass-clad steel – Pipe: Fiberglass, flexible plastic 2. Galvanic cathodic protection – STI-p3 3. Impressed current cathodic protection – Older systems used in retrofits – Impressed current, internal epoxy lining or both Equipment: Non-Metal Equipment: Galvanic Steel Equipment: Impressed Current Equipment: Internal Lining Corrosion Operation and Maintenance • Non-Metal: None. • Galvanic: None. • Impressed current: Check rectifier every 60 days and log results. – Looks for trends over time. – Zero value is not good, no power, no protection. Corrosion Testing • Galvanic and impressed current system must have cathodic protection test done: – Every 3 years, – By a certified tester (NACE), – As close to original test conditions as possible. • Also, impressed current systems must have current levels checked every 60 days. (Most operators check every 30 days.) Corrosion Testing • Tester has certain test standards to follow. • All test failures should be promptly investigated. • Tank or piping must demonstrate it has sufficient current to overcome corrosion in soils. • Most common target is 850 mV. • 100 mV shift acceptable. Corrosion Testing • Test contact at test station or inside tank. • If no test station, should have written procedure. Corrosion Testing: Steel Pipe • Make sure steel pipe is protected from corrosion. • Pipe may or may not be electronically connected to cathodically protected tank. • Unprotected steel pipe should be removed. Corrosion Testing: Liner Only • Internal liner must be inspected after 10 years. • Also must be inspected every 5 years thereafter. • A few different testing options available. Corrosion Problems Current STIp3 Tank • Cracking isolation bushing. • Coating damaged at installation. Current Corrosion Problems Impressed Current • Anode wires damaged. • Stray current. • Rectifier damaged. • Large decrease in current. Corrosion Record Keeping • For non-metal materials: keep installation documents. • For galvanic systems, keep last two cathodic protection test results. • For impressed current, keep last three cathodic protection test results plus 60-day monitoring log. (Most operators do it every 30 days.) Corrosion Considerations • Check metal flex connectors even if not required. • Check rectifier every 30 days and know who to call to troubleshoot. Suspected Releases Suspected Releases • About Leaks and Spills • Investigate and Confirm • Reporting • System tests • Site Assessment • Off-site impact • Actual releases • Notify Can you find the leak? About Leaks and Spills: Sources Other 16% Tank 5% Delivery 32% Dispenser 12% Piping 35% Other Sources Include: Fuel Filters, Outlet Valve, and Human Spilling About Leaks and Spills: Causes Unknown 8% Other 16% Phys/Mech Damage 19% Loose Component 12% Corrosion 9% Spill/Overfill 36% Other Causes Include: Vandalism, Valve Failure, Contractor Accident, Other Human Error About Spills and Leaks: Detection Closure/ Removal 8% Other 2% Leak Detection 22% Visual/ Olfactory 68% Suspected Releases Investigate and confirm • Upon discovery, owner/operator must take immediate action to investigate. • If cannot verify the event was false alarm, must report to regulatory agency. • If false alarm: No evidence of release • If release: Contact regulatory agency, hire contractor, develop investigation cleanup plan, • Investigation complete in 7 days. Suspected Releases Reporting • Notify regulatory agency within 24 hours of discovery of potential problem, including: – Obvious signs of leakage, – Unusual operating conditions, or – Monitoring alarm. Suspected Releases Unusual operating conditions can include: • Erratic dispenser, • Sudden loss of product, • Widely fluctuating water levels, • Unexplained water in tank. Suspected Releases Other scenarios of concern are: • Fuel in secondary containment area. – Double wall tank – Piping sumps • Monitoring results that show alarm situation. Leaking flex connector with loss less than detectable limit Suspected Releases System Tests • Owner/operator may have to conduct tightness test to confirm if release occurred. • Owner/operator may have test any double-wall systems. • Repair or replace damaged pieces of equipment • Shut down use of UST system until corrected. Suspected Releases Site Assessment • May be required if: – Obvious sign of problem, – Tank or pipe tests tight but obvious problem anyway (like sheen in creek), or – Directed by regulatory agency. • Site-specific soil and ground water sampling. Suspected Releases Off-Site Impacts • Regulatory agency may require owner to determine whether or not any off-site impact exists observed by agency or another person. Clean it up…Immediately! Contain and cleanup all spills. Report spill or overfill of 25 gallons within 24 hours (Federal Requirement). Report any amount that causes a sheen on nearby water surface. Even if not reportable, keep a record. Summary • • • • UST systems can and do leak today. Federal facilities must comply with all UST laws. Leak detection is a critical part of fueling operations. Overfill prevention equipment and activities are vital in stopping large releases. • Corrosion protection can reduce rust-related problems. • Suspected releases must be promptly addressed. • Trained staff should be able to intercept many problems.