UNDERGROUND STORAGE TANKS

Underground Storage Tanks at

Duke

• Duke Medical Center

– 8 permitted USTs located on medical campus

– Range in size from 2,000 gallons to 30,000 gallons

• Proper management of these USTs will hopefully prevent a future LUST or a large surface spill of petroleum products

USTs at Duke

• Operating permits are required for all USTs in NC (15A NCAC 2N)

– Associated yearly fee

– Compliance questionnaire must be completed and signed before the permit will be issued.

UNDERGROUND STORAGE TANKS

• 40 CFR 280 - Technical Standards and

Corrective Action Requirements for Owners and Operators of Underground Storage

Tanks (USTs).

Underground Storage Tanks

General Standards

• No person may install an UST system for the purposes regulated substances unless the

UST system:

– will prevent releases due to corrosion or structural failure;

– is cathodically protected against corrosion, constructed of noncorrodible material, steel clad with a noncorrodible material, or designed to prevent the release of any stored substance; and

Underground Storage Tanks

– Is constructed or lined with material that is compatible with the stored substance.

• A UST system may be installed if a corrosion expert determines that the site will not be corrosive enough to cause a release due to corrosion during operating life.

Underground Storage Tanks

• Performance Standards for New UST

Systems

– Tanks and Piping

• must be properly designed and constructed, any part underground must be protected from corrosion

• constructed of fiberglass reinforced plastic, or

• constructed of steel and cathodically protected in the following ways:

– tank is coated with suitable dielectric material;

– field installed cathodic protection designed by expert;

– Impressed current systems are designed to allow determination of current operating status and systems maintained.

Double Walled Fiberglass Tank

Underground Storage Tanks

• constructed of steel fiberglass reinforced plastic composite; or

• constructed of metal without additional corrosion protection measures provided that

– corrosion expert determines corrosion at site is not a hazard

– owners/operators maintain records that demonstrate compliance with corrosion expert’s findings

– implementing agency determines tank construction and corrosion protection sufficient to prevent the release or threatened release of any stored regulated substance in a manner that is no less protective of human health and the environment

Underground Storage Tanks

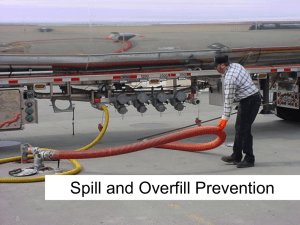

– Spill and Overfill Protection

• to prevent spilling and overfilling associated with product transfer to the UST system owners/operators must use the following equipment:

– spill prevention equipment that will prevent a release of product when the transfer hose is detached from the fill pipe

– overfill prevention equipment that will:

» automatically shut off flow into the tank when the tank is no more than 95% full, or

Underground Storage Tanks

» Alert the transfer operator when the tank is no more than 90% full be restricting the flow into the tank or triggering the high-level alarm, or

» restrict flow 30 minutes prior to overfilling, alert the operator with a high level alarm one minute before overfilling, or automatically shut off the flow into the tank

• Owners/operators are not required to use spill and overfill prevention equipment if alternated equipment is used that is determined by the implementing agency to be no less protective of human health and the environment or the UST system is filled by transfers of no more than 25 gallons at a time.

Underground Storage Tanks

– Installation

• All tanks and piping must be properly installed in accordance with a code of practice developed by a national recognized association or independent testing laboratory and in accordance with the manufacturer’s instructions.

– Certification

• owners/operators must provide certification of compliance on the UST notification form

Installation of an

UST

Underground Storage Tanks

• Upgrading existing USTs

– Tank upgrading requirements

• tank may be upgraded to meet one of the following requirements

– Interior lining - must be installed in accordance with

280.33 and within 10 years after lining and 5 years thereafter, lining must be inspected and found to be structurally sound

– Cathodic protection - must meet the requirements of

280.20(a)(2) and the integrity of the tank is ensured using:

» internally inspected and assessed to ensure the tank is structurally sound and free of corrosion holes prior to installation

Underground Storage Tanks

» tank had been installed for less than 10 years and is monitored monthly for releases, or

» tank has been installed for less than 10 years and is assessed for corrosion holes by conducting two tightness tests that meet the requirements of

280.43(2). The first tightness test must be conducted prior to installation of system. The second must be conducted between 3 and 6 months following first operation on the system, or

» tank is assessed for corrosion holes by a method that is determined by the implementing agency to prevent release

Underground Storage Tanks

– Internal lining combined with cathodic protection

» lining installed in accordance with 280.33

» cathodic protection system meets requirements of

280.20

– Piping upgrades

» metal piping that routinely contains regulated substances and is in contact with the ground must be cathodically protected .

– Spill and overfill protection

» must comply with the new UST system spill and overfill prevention equipment requirements specified in 280.20(2).

Underground Storage Tanks

– Notification Requirements

• Must notify state and local agency when bringing tank system online and certification of compliance with regulation

– NC UST Section Forms UST-6A/B, UST-15, etc.

• General Operating Requirements

– Owners/operators must ensure that releases due to spilling or overfilling do not occur.

– Cathodic protection systems must be inspected for proper operation by a qualified tester.

Underground Storage Tanks

• Compatibility

– Owners/operators must use an UST system made of or lined with materials that are compatible with the substance stored in the

UST system.

• Repairs Allowed

– Owners/operators must ensure that repairs will prevent releases due to structural failure or corrosion as long as the UST system is used to store regulated substances.

Underground Storage Tanks

• Repairs to fiberglass-reinforced tanks may be made by the manufacturer’s authorized representative

• Leaking metal pipes must be replaced. Fiberglass pipes and fittings may be repaired.

• Repaired tanks and lines must be fit tested.

• Repaired tanks are internally inspected

• Repaired portion of tank must be monitored monthly, or

• as specified by implementing agency

• Within 6 months following the repair of any cathodically protected UST system must be tested in accordance with the regulations to ensure proper operation,

Underground Storage Tanks

• Owner/operators must maintain records of each repair for the remaining operating life of UST system.

• Release Detection

– must provide a method, or combination of methods of release detection that:

• can detect a release from any portion of the tank and the connected underground piping that routinely contains product,

Underground Storage Tanks

• Is installed, calibrated, operated, and maintained in accordance with the manufacturer’s instructions; and

• meet the performance requirements in 280.43 or

2880.44.

• Any existing UST system that can not apply a method of release detection must close the system.

• Methods

– Inventory control, manual tank gauging, tank tightness testing, vapor monitoring, groundwater monitoring, interstitial monitoring, line leak detectors

• Reference

• http://www.wastenotnc.org/ust/ust_main.html

– http://www.wastenotnc.org/ust/forms.html