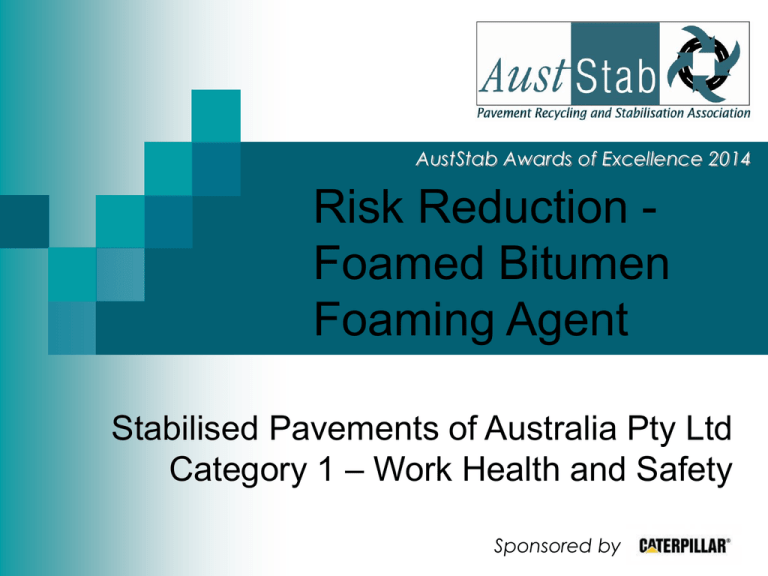

Foamed Bitumen Foaming Agent

advertisement

AustStab Awards of Excellence 2014 Risk Reduction Foamed Bitumen Foaming Agent Stabilised Pavements of Australia Pty Ltd Category 1 – Work Health and Safety Sponsored by Foamed Bitumen Stabilisation Foaming agent must be added to enhance the bitumen foaming properties Current foaming agent is dangerous good and hazardous substance Hazard Identification SPA identified that a substantial number of risks could be reduced in the workplace through substitution of existing foaming agent Development of Alternate Foaming Agent Identification of product standards Existing material properties/composition Handling and application Laboratory trial program Field trial program Laboratory Results No Additive Current Interfoam Bitumen Temperature (⁰C) 180 180 180 Water Added (% of Bitumen) 2.51 2.51 2.65 Expansion Ratio (ratio of maximum foamed volume to original volume) 8 10 14 Half-life (seconds) 10.7 15.7 60 Standards require a minimum expansion ratio of 10 and half-life of 20 seconds RMS Port Macquarie Field Trial Average Results for One Bitumen Run Using Interfoam Bitumen Temperature (⁰C) 184 Water Added (% of Bitumen) 2.6 Expansion Ratio (ratio of maximum foamed volume to original volume) 11.2 Half-life (seconds) 19.6 Product Hazard Comparison Current Product Interfoam Dangerous Good Hazardous Good Hazardous Good Strong odour – inhalation of product will result in severe headaches and nausea Minor odour – has not caused headaches or nausea from any SPA trials 35⁰C flashpoint 61⁰C flashpoint – less flammable product Highly aquatic toxicity Lower aquatic toxicity