WTP No. 2 Concentrate Zero Liquid Discharge

Water Treatment Plant No. 2

Concentrate Zero Liquid Discharge

August 30, 2011

McKim & Creed, Inc.

• Tommy Brown, P.E.

– Vice President, Project QA/QC

• Craig Wells, P.E.

– Principal-in-Charge

• Phil Locke, P.E.

– Senior Project Manager

• Ryan Popko, P.E.

– Assistant Project Manager, Lead Project Engineer

Water Treatment Plant No. 2 Overview

• Membrane Softening Water Treatment Plant

– Fresh groundwater wells provide the source water

– Produces drinking water

– Produces concentrate or “reject” stream

– Concentrate discharged into Royal Palms

Waterway

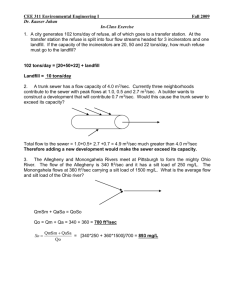

Current Plant Design Capacity

• Permitted production is

~6.3 Million Gallons per

Day (MGD)

• Source water required is ~7.5 MGD

Reject water

~1.2 MGD

6

5

4

8

7

3

2

1

0

Reject

Drinking

Water

Groundwater

Capacity

Drinking water

~6.3 MGD

Administrative Order

• Administrative Order for Concentrate Disposal

– EPA determined current concentrate discharge permit is not allowed by the Clean Water Act

– FDEP notified City that concentrate disposal permit would not be renewed

– Administrative Order requires City to devise an alternate method of disposing of the concentrate

Background

• City performed an evaluation of concentrate disposal alternatives based on:

– Costs

– Regulatory compliance

― Technical feasibility

― Environmental benefits

• Evaluation selected Zero Liquid Discharge for

Pilot Study

• Zero Liquid Discharge Pilot Study confirmed treatability, feasibility, and economics as favorable

Zero Liquid Discharge (ZLD) Overview

• Treats concentrate stream to remove excess mineral content

• Treated stream blended with finished water from water plant

• Process is integrated into existing water plant; will operate as one facility

• Eliminates concentrate discharge from water plant

Groundwater

Future Situation

No Liquid Discharge

Project Delivery Method

• City selected an Original Equipment

Manufacturer (OEM)

– Advertised Request for Qualifications (RFQ)

• Six OEMs responded

• Evaluation included technical process and experience information

• City selected three OEMs for further consideration

– Advertised Request for Proposal (RFP)

• Evaluation included pricing information

– Selected Doosan Hydro Technology

Project Delivery Method

• City selected a Design Engineer

– Requested technical qualifications (RFQ) from the three firms under contract to provide utility engineering services

• Evaluation utilized qualifications based selection per state law

– Selected McKim & Creed

Project Delivery Method

• Future Actions

– Design to be performed by McKim & Creed

• Design will incorporate the OEM equipment that has been selected by the City

• Technical plans and specifications will be prepared to include equipment provided by the OEM

– Advertisement for a General Contractor (GC)

• Price competition, based on using OEM equipment and pricing provided to City

Project Costs

Total Estimated Project Costs $7.3M vs. $7.5M budget

• Construction Costs

• $2.15M OEM (quote)

• $4.00M General Contractor (still subject to bid environment)

• $0.24M Bidding and Engineering Services during

Construction (quote)

• Design Costs

• $0.58M Engineering (quote)

• $0.11M OEM Services (quote)

• Integration Costs

• $0.22M Supervisory Control and Data Acquisition

System (quote)

Benefits of Project

• Achieves regulatory compliance

• Increases water plant design capacity at build-out by

~1.2 MGD

• Eliminates discharge permit and associated sampling costs

• Meets the Consumptive Use Permit requirement for

Alternative Water Supply

• Design incorporates City’s green initiatives

– Water Conservation

– Waste Recovery

• Delays costs associated with future expansions

Project Schedule

• Work Order issued for design: September

2011

• Award construction contract: May 2012

• Substantial completion and Administrative

Order compliance: April 2013