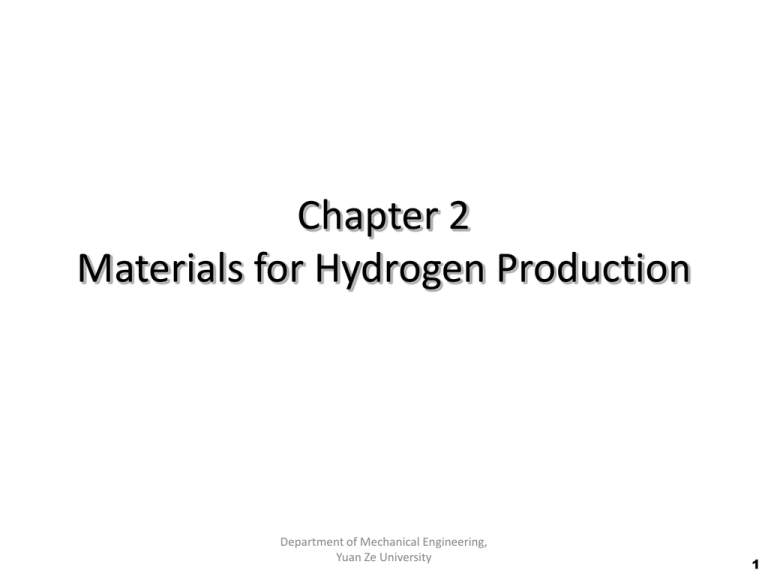

Chapter 2 Materials for Hydrogen Production

advertisement

Chapter 2 Materials for Hydrogen Production Department of Mechanical Engineering, Yuan Ze University 1 • Hydrogen can be produced using diverse, domestic resources including fossil fuels, such as natural gas and coal (with carbon sequestration); nuclear; biomass; and other renewable energy technologies, such as wind, solar, geothermal, and hydroelectric power. • The overall challenge to hydrogen production is cost reduction. For cost-competitive transportation, a key driver for energy independence and therefore the hydrogen economy, hydrogen must be comparable to conventional fuels and technologies on a per-mile basis in order to succeed in the commercial marketplace. • The U.S. Department of Energy supports the research and development of a wide range of technologies to produce hydrogen economically and in environmentally friendly ways. Department of Mechanical Engineering, Yuan Ze University 2 DOE's hydrogen cost goal Department of Mechanical Engineering, Yuan Ze University 3 DOE's hydrogen cost goal Department of Mechanical Engineering, Yuan Ze University 4 Current Technology The development of clean, sustainable, and cost-competitive hydrogen production processes is key to a viable future hydrogen economy. Hydrogen production technologies fall into three general categories: thermal processes, electrolytic processes, and photolytic processes. 1. Thermal Processes Some thermal processes use the energy in various resources, such as natural gas, coal, or biomass, to release hydrogen, which is part of their molecular structure. In other processes, heat, in combination with closed-chemical cycles, produces hydrogen from feedstocks such as water—these are known as "thermochemical" processes. Reforming of Natural Gas Gasification of Coal Gasification of Biomass Reforming of Renewable Liquid Fuels High-Temperature Water Splitting Department of Mechanical Engineering, Yuan Ze University 5 2. Electrolytic Processes Electrolytic processes use electricity to split water into hydrogen and oxygen, a process that takes place in an electrolyzer. Hydrogen produced via electrolysis can result in zero greenhouse gas emissions, depending on the source of the electricity used. The source of the required electricity—including its cost and efficiency, as well as emissions resulting from electricity generation—must be considered when evaluating the benefits of hydrogen production via electrolysis. The two electrolysis pathways of greatest interest for wide-scale hydrogen production, which result in near-zero greenhouse gas emissions, are electrolysis using renewable sources of electricity and nuclear high-temperature electrolysis. 3. Photolytic Processes Photolytic processes use light energy to split water into hydrogen and oxygen. Currently in the very early stages of research, these processes offer long-term potential for sustainable hydrogen production with low environmental impact. Photobiological Water Splitting Photoelectrochemical Water Splitting Department of Mechanical Engineering, Yuan Ze University 6 Timing of R&D for Hydrogen production technology Department of Mechanical Engineering, Yuan Ze University 7 Distributed Natural Gas Reforming Department of Mechanical Engineering, Yuan Ze University 8 Bio-Derived Liquids Reforming Department of Mechanical Engineering, Yuan Ze University 9 Coal and Biomass Gasification Department of Mechanical Engineering, Yuan Ze University 10 Thermochemical Production (Using a Heat-Driven Chemical Reaction To Split Water) Department of Mechanical Engineering, Yuan Ze University Department of Mechanical Engineering, Yuan Ze University 11 Issues in Hydrogen Production Using Gasification • Gasifiers are used commercially to react a carbon-containing material with water (or steam) and oxygen under reducing conditions (shortage of oxygen), producing chemicals used as feedstock for other processes, fuel for power plants, or steam for other processes. • Gasifiers used in industry for chemical processing are high-temperature, highpressure reaction chambers, typically operating between 1,250 and 1,575 oC, and with pressures between 300 and 1,200 psi. • The gasification process produces CO and H2 as the primary products, along with by-products of CO2 and minority gases. Because the gasification process is intentionally conducted with a shortage of oxygen needed for complete combustion of the feedstock carbon, the partial oxidation shown in equation 1.1 occurs: C H2O gas O2 CO H2 CO2 minoritygases by products (1.1) By-products include mineral impurities in the carbon feedstock that become ash or slag. Department of Mechanical Engineering, Yuan Ze University 12 Department of Mechanical Engineering, Yuan Ze University 13 • A number of carbon feedstocks can be used as the carbon sources, with the most common being coal, methane, or by-products/tails from the petrochemical industry. • Since gasification occurs in an environments with a shortage of oxygen (reducing), the general balanced chemical reaction that occurs throughout the gasification process for a hydrocarbon can be written as in equation 1.2: x y C x H y O2 xCO H 2 heat, C * (1.1) 2 2 * C originates from excess feedstock carbonin the reducing gasification environm ent. Department of Mechanical Engineering, Yuan Ze University 14 • Gasification is considered a noncatalytic process that involves a number of endothermic and exothermic reactions, with the overall process being exothermic. • Ideally, the amount of excess carbon should be small, about 1.0 wt %, but is dependent upon variables such as the gasifier type, carbon feedstock, O2/C ratios, and the level of carbon beneficiation. • Because of the controlled oxygen shortage, gasification produces a primary product of CO and H2, call synthesis gas (shortened to syngas), that is commercially valuable, along with a number of byproducts that depend on the process and impurities in the carbon feedstock. The byproducts can include excess C, sulfur, ash, soot, metal oxides, and gases (common gaseous impurities include CO2 and H2S; low-level impurity gases include CH4, NH3, HCN, N2 and Ar). Department of Mechanical Engineering, Yuan Ze University Department of Mechanical Engineering, Yuan Ze University 15 Carbon Feedstock For Gasification Department of Mechanical Engineering, Yuan Ze University Department of Mechanical Engineering, Yuan Ze University 16 Gasification Products • Syngas (H2 and CO) ― Used to generate heat, chemicals, electricity, or “town gas.” • Chemicals ― H2, CO or both are used as chemical feedstock for the production of ammonia, oxo-chemicals, methanol, acetic acid, hydrogen, fertilizer, or synthetic hydrocarbon fuels (zero-sulfur diesel and other transportation fuels) manufactured using Fischer-Tropsch processing, and other chemicals. • Electricity ― Produced from the combustion of syngas or from gasification steam. • Steam ― Gasification or combustion by-product used in plant applications, power generation, and “over the fence” needs of nearby companies. • Gasification by-products ― (used for enhanced oil and methane recovery, the food industry, urea fertilizer, possible enhanced greenhouse production, proposed geological disposal), S, N2, Ar, Ni, and V. Department of Mechanical Engineering, Yuan Ze University • Iron metal production ― CO, H2 or both are used to reduce iron oxide into metallic iron for steel production by the following reactions: Fe2O3 3CO 2 Fe 3CO2 Fe2O3 3H 2 2 Fe 3H 2O – Iron produced by the direct reduction of iron oxide is called direct reduced iron (DRI) and is typically made using natural gas. – Two gasification facilities are designed to use CO and H2 ―one has been in operation since May1999 (Saldanha Steel, near Cape Town, South Africa); the other is under construction in South Korea. – These DRI facilities are designed to be syngas fuel flexible, capable of using syngas CO and H2 combinations ranging from 100 % CO to 100 % H2. Department of Mechanical Engineering, Yuan Ze University Environmental Advantages • • • • • • • Gaseous emissions – Very low emissions compared to other processes ― NOx, SOx and particulate emissions below current Environmental Protection Agency (EPA) standards. – Organic compound emissions are below environmental limits. – Mercury emissions can be reduced to acceptable environmental levels. SOx can be processed into a marketable by-product. Ash can be liquefied into a slag that passes toxicity characteristic leaching procedure (also known as TCLP) testing in most instances. CO2 can be contained and recovered in the closed loops of gasifiers for remediation/reuse. Low-value carbon materials with environmental issues are easily utilized as a carbon feedstock. Gasifiers have product flexibility that allows output to be market driven. Gasification is a thermally efficient process. Department of Mechanical Engineering, Yuan Ze University Department of Mechanical Engineering, Yuan Ze University 19 Hydrogen Generation by Gasification • In the U.S., the total H2 consumption during 2003 was about 3.2 trillion cubic feet, with most utilized in petroleum refining and ammonia production. • In the U.S., the most H2 is generated by steam methane reforming, which constitutes about 85 % of the total production. • Gasification of hydrocarbon materials like coal, petcoke, and heavy oil, however, is starting to play a larger role in the production of H2 . • The commercial production of typically involves one of the following processes: 1. steam reforming 2. water shift gas reaction 3. partial oxidation 4. autothermal reforming. Department of Mechanical Engineering, Yuan Ze University Department of Mechanical Engineering, Yuan Ze University 20 • Steam reforming, also known as steam methane reforming, involves reacting a hydrocarbon with steam at high temperature (700 to 1,000 ゚C) in the presence of a metal catalyst, yielding CO and H2. Of the processes used to make H2, steam reforming is the most widely practiced by industry and can utilize a variety of carbon feedstocks, ranging from natural gas to naphtha, liquid petroleum gas (LPG), or refinery off-gas. Steam reforming, in its simplest form using methane as a feedstock, follows the general reaction (1.3) • Water shift gas reactions form CO2 and H2 using water and CO at elevated temperature, as shown in equation 1.4. The reaction may be used with catalysts, which can become poisoned by S if concentrations are high in the feed gas. The water shift gas reaction is used as a secondary 4 means of2processing gas syngas when greater 2 amounts of H2 are desired from gasification. (1.4) CH H O CO 3H CO H2O gas H2 CO2 Department of Mechanical Engineering, Yuan Ze University Department of Mechanical Engineering, Yuan Ze University 21 • Partial oxidation is the basic gasification reaction, breaking down a hydrogenated carbon feedstock (typically coal or petroleum coke) using heat in a reducing environment, producing CO and H2 (equation 1.2). A number of techniques are utilized to separate H2 from the CO in syngas or to enrich the H2 content of the syngas. These include H2 membranes, liquid adsorption of CO2 or other gas impurities, and the water shift gas reaction (equation 1.4). x y C x H y O2 xCO H 2 2 2 • Autothermal reforming is a term used to describe the combination of steam reforming (equation 1.3) and partial oxidation (equation 1.2) in a chemical reaction. It occurs when there is no physical wall separating the steam reforming and catalytic partial oxidation reactions. In autothermal reforming, a catalyst controls the relative extent of the partial oxidation and steam reforming reactions. Advantages of autothermal reforming are that it operates at lower temperatures than the partial oxidation reaction and results in higher H2 concentration. Department of Mechanical Engineering, Yuan Ze University Department of Mechanical Engineering, Yuan Ze University 22 • Types of Commercial Gasifiers Department of Mechanical Engineering, Yuan Ze University Department of Mechanical Engineering, Yuan Ze University 23