ppt - Sustainable Sanitation

advertisement

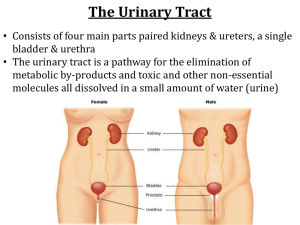

Module 4.10 Ecosan versus conventional sanitation How can dry UD ecosan system be compared with a conventional systems (open defecation, latrine pit, water-borne)? 4 Swedish systems with nutrient recovery compared 1. 2. 3. 4. Reference. Conventional system. N & P removal in WWTP. Effluent: 8 mg N & 0.24 mg P/l. Sludge incinerated, ash landfilled. Urine. 80% of urine diverted & recycled as fertiliser. Rest = reference Blackwater. Vacuum toilets. Collected blackwater anaerobically digested, sanitised & recycled as fertiliser. Rest = reference Sludge. Sludge recycled as fertiliser. Rest = reference Recycled plant available NPKS (% of tot) Recycled plant available NPKS 80 N P K 70 60 50 40 30 20 10 0 Reference Urine Blackwater Sludge PhoStrip KREPRO BioCon S Energy use 1000 Pumping Treatment Transports P-recovery Spreading Chemical fertiliser Energy use (MJ/pers, yr) 900 800 700 600 500 400 300 200 100 0 Reference Urine Blackwater Sludge PhoStrip KREPRO BioCon Non-renewable resource use (10e-16/person, yr) Total use non-renewable 600 P,K,S Oil, gas Electricity 500 400 300 200 100 0 Reference Urine Blackwater Sludge Other studies of sorting systems • Many systems analysis have found same results: • Urine diversion – decreases water emissions – gives lots of useful fertiliser – saves chemical fertiliser – saves energy Recycled NPK vs degree of diversion Recycled NPK [kg/p,yr] 3,0 2,5 Urine Sludge 2,0 1,5 1,0 0,5 0,0 N N N P P P K K. K Conv 40% 100% Conv 40% 100% Conv 40% 100% Water emissions vs degree of diversion Wateremissions [kg/p,year] 0,8 0,7 Sew plant Field Landfill Chemicals 0,6 0,5 0,4 0,3 0,2 0,1 0,0 N Conv N 40% N 65% N 100% P Conv P 40% P 65% P 100% Energy usage vs degree of diversion Energy usage [MJ/p,year] 350 Fertiliser Oil Electric 300 250 200 150 100 50 0 Conv 40% Urine 65% Urine 100% Urine http://www.stockholmvatten.se/pdf_arkiv/english/Urinsep_eng.pdf Energy usage [MJ/p,yr] Energy usage vs transport distance 400 350 300 250 200 150 100 50 0 Fertiliser Oil Electricity Conv. 1 km 33 km 100 km 200 km 1 km 33 km 100 km 200 km Urine Urine Urine Urine Urine Urine Urine Urine truck truck truck truck t+t t+t t+t t+t System boarders • What to include and what to exclude? • UDD – Solid organic waste – Energy production – Fertiliser production • Food production – Delivered sanitational function • Greywater • Drinking water • Other waste Productive Sanitation Excreta Food N=2.8kg P=0.4kg K=0.5 kg Nutrient flow per person and year N=2.8kg P=0.4kg K=0.5 kg Fertiliser Value of fertiliser - urine • • • • 2.8kg N = 6kg Urea 0.5€/kg = 3€ 0.4 kg P = 2kg TPS ~0.4€/kg = 0.8€ 0.5 kg K = 1kg KCl ~0.4€/kg = 0.4€ Total value 4.2€ per person and year = 0.012€ per person day • Value per jerry can 20L ~ 0.23€ • Can at least pay for transport and spreading • Non-subsidised Cost for ecosan • • Pour flush toilet 1900 INR (35€) EcoSan toilet 4200 INR (77€) Fertiliser per family Fertiliser Amount, kg Difference Nutrients kg 160 4 persons NPK 10-5-20 2,2 16,0 10,0% 18,2 N -1,2 3,6 2,2% 2,32 P NPK 10-5-20 Indian, price 5.5 INR/kg (0.1€) Value 880 INR/year (16€) Present value years 2-10: 5070 INR! (93€) Conclusion • Pour flush toilet cost: 1900 R • EcoSan toilet cost: 4200 R – Income from fertiliser: 5080 R • Fertiliser can pay for toilet in 10 years, not just additional cost! Additionally • Less hazard to ground & surface water – Saves on drinking water – Protects health Cost sharing • Having no toilet has lowest investment & direct running costs! • Only type of toilet where the investment can directly pay off • The cost of Ecosan is compatitive compared with any other ecological solution • The cost is largely paid by household when building – no risk for corruption at municipal level – higher cost acceptance • More private enterprise – more competition – saves taxes