TECHNICAL TEXTILES

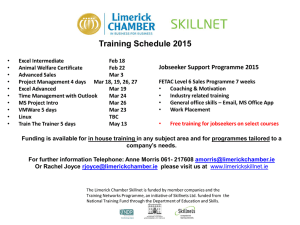

advertisement

GROWTH POTENTIAL AND PROSPECTS IN INDIA Reliance Industries Limited 19 Mar 2010 one of the most promising and faster growing areas for global and indian textile industry indispensible part of human life encompasses immense range and diversity of raw materials, processes, products and applications accounts for over one-quarter of all textile consumption in weight terms plays crucial role in indian economy and infrastructural development 19 Mar 2010 technical textiles are defined as textile materials and products used primarily for their technical performance and functional properties rather than their aesthetic or decorative characteristics depending on the product characteristics, functional requirements and end-use applications, these have been grouped into 12 segments 19 Mar 2010 agrotech (agriculture, horticulture and forestry) buildtech (building and construction) clothtech (shoes and clothing) geotech (geotextiles, civil engineering) hometech (furniture, upholstery, interior furnishing, household textiles, floor covering) indutech (filteration, cleaning and other industrial uses) medtech (medical, healthcare and hygiene) mobiltech (automobiles, shipping, railways and aerospace) oekotech (environmental protection) packtech (packaging) protech (person and property protection) sporttech (sport and leisure) 19 Mar 2010 world market for technical textiles at 21 mn tonnes (us$ 120 bn) during 2007-08 is expected to increase to 26 mn tonnes (us$139 bn) by 2012 with a cagr of 4 - 5 % depending on the area of application fibre consumption in technical textiles was 22 % of total fibres consumed in 2005 the drivers for future growth are expected to be asian countries like china and india. the growth in asia is expected to be 6.5 percent while it would be merely 2.2 percent in developed countries sector-wise higher growth rates are for indutech, buildtech, medtech, geotech, packtech and agrotech. but protech is important in view of safety. 19 Mar 2010 Technical textiles 22% Textle consumption 78% 19 Mar 2010 QUANTITY (mn TONNES) VALUE (bn US$) 19 Mar 2010 2005 2010 19.683 23.774 CAGR % (VOL.) 3.8 106.899 127.287 3.4 REGION / COUNTRY 2005 2005 2010 2010 05 - 10 VOL. (mn T) VALUE (US$ bn) VOL. (mn T) VALUE (US$ bn) CAGR % (VOL.) EUROPE (WEST) 4.107 23.968 4.760 21.047 3.0 EUROPE (EAST) 0.666 4.583 0.817 5.225 4.2 AMERICA (NORTH) 4.774 23.710 5.591 27.561 3.2 AMERICA (SOUTH) 1.004 6.348 1.230 7.255 4.1 ASIA 8.091 48.401 10.156 65.156 5.0 INDIA 1.573 4.905 2.075 6.774 5.8 OCEANIA 0.116 0.578 0.141 0.712 3.9 127.28 3.87 TOTAL 19 Mar 2010 19.683 106.899 23.774 USA 23% Rest of World 32% India 3% Western Europe 22% Japan 7% China 13% 19 Mar 2010 SECTOR 2005 2005 2010 2010 CAGR % CAGR % VOLUME VALUE VOLUME VALUE VOLUME VALUE AGROTECH 1615 6568 1958 8079 3.55 3.84 BUILDTECH 2033 7296 2591 9325 4.63 4.73 CLOTHTECH 1413 7014 1656 8306 2.95 3.19 GEOTECH 319 927 413 1203 4.94 4.98 HOMETECH 2499 7622 2853 8778 2.70 2.66 INDUTECH 2624 16687 3257 21528 3.98 4.85 MEDTECH 1928 6670 2380 8238 4.43 4.33 MOBILTECH 2828 26861 3338 29282 3.02 1.34 PACKTECH 2990 5329 3606 6630 3.52 4.20 PROTECH 279 5873 340 6857 3.63 2.82 SPORTTECH 1153 16052 1382 19062 3.40 3.21 OEKOTECH 287 1039 400 1389 6.45 5.67 19681 106899 23774 127288 3.59 3.80 TOTAL 19 Mar 2010 Other Fabrics 2% Knitted Fabrics 5% Non woven Fabrics 20% Woven fabrics 73% 19 Mar 2010 FIBRE TYPE 2000 2005 2010 CAGR % NATURAL 3462 3839 4447 2.54 MAN-MADE/ INORGANIC 13252 15843 19327 3.85 TOTAL 16714 19682 23774 3.59 19 Mar 2010 POLYESTER - 25 % POLYOLEFINS - 25 % GLASS - 15 % JUTE, COIR, ETC. - 14 % COTTON - 7% VISCOSE - 3% OTHER CELLULOSICS - 3% POLYAMIDE - 7% ARAMID AND CARBON FIBRES - 1 % 19 Mar 2010 19 Mar 2010 19 Mar 2010 19 Mar 2010 fabric unspun fibres yarns - 67 % - 24 % - 09 % fibre products include fibre reinforced concrete and composites, cushioning, fillings, insulation & sports equipments, toys yarn products include sutures, ropes, fishing gears, shoe laces, swings fabrics can be woven, knitted and non-woven and cover all sectors of technical textiles 19 Mar 2010 Unspun fibres 24% Fabric 67% 19 Mar 2010 Yarn Type Products 9% INDIGENOUS PRODUCTION OF TECHNICAL TEXTILES IS LIMITED AND SCATTERED MAINLY IN SMALL & MEDIUM SECTORS THE DEMAND FOR MANY ITEMS IS MET THROUGH IMPORTS e.g. DEFENCE AND POLICE LARGE UNTAPPED POTENTIAL EXISTS FOR POTENTIAL INVESTORS SOME OF THE PRODUCTS CAN BE PRODUCED BY MINOR ALTERATION IN EXISTING SET UP 19 Mar 2010 in many developed countries (e.g. usa and japan) technical textiles account for over 35 percent of the textile industry’s output as against 19 % for china and 5 % for india primarily active in the clothtech, packtech and sporttech sectors limited to commodity products very little presence in high tech segments there is a general perception that technical textiles are predominantly produced in large scale sector but it is true only to limited extent 19 Mar 2010 indigenous production and ‘value for money’ pricing concept will explode the market India, the fourth largest economy in terms of purchasing power parity (ppp) (after usa, china & japan) is a growing market of one billion plus people, of which 300 million people are middle class consumers the consumption of disposable segment of technical textiles is directly related to the disposable income considering the above, over all growth of technical textiles is estimated at 14 percent per annum with appropriate policy regime and accordingly the market size for technical textiles will increase from rs. 37100 crores in 2007-08 to rs. 62420 crores in 2012-13 (icra study) at a cagr of 11 % 19 Mar 2010 the value addition in technical textiles is steadily shifting from raw materials and intermediate products to downstream industries where india has a strong base low cost skilled labour is highly competitive as compared to developed countries decentralised sector’s contribution in technical textiles is significant for their growth in india indian textile industry is fundamentally strong which can be useful in commodity markets of technical textiles through cost competitive structure in the high niche market, india has advantage of network of r&d institutions for developing new technologies 19 Mar 2010 dominance of decentralised sector – inadequate resources and finance absence of regulatory legislation absence of required standards on quality of products and codes of practices deterrants for entrepreneurs: doubt about future market potential of technical textiles in view of absence of regulation and needed consumtion huge capital costs involved for machinery, raw materials and equipment sustained promotional efforts and substantial investment needed for market development limited experience in production and use of technical textiles outdated existing regulatory mechanism 19 Mar 2010 lack of basic infrastructure, skilled manpower, testing facilities, training & educational facilities negligible investment in r&d on technical textiles lack of comprehensive database on technical textiles lack of awareness and benefits of using technical textiles among users hesitation in accepting world proven cost effective technologies poor understanding of product properties in regard to its constructability, durability, structural integrity, functional utility, fibre composition and its installation and handling 19 Mar 2010 import intensive nature making their cost prohibitive no quality benchmark for technology for technical textiles non-availability of main raw materials i.e. specialty fibres at competitive and affordable prices limited demand in view of absence of required standards and regulations lack of awareness of benefits of using technical textiles little emphasis on health, safety and environmental aspects hesitation in adopting latest world proven efficient and cost effective technologies little understanding among users about the type of product and its properties regarding constructability, durability, structural integrity, survivability and functional utility 19 Mar 2010 Sl. N o. TT SECTOR NO LAW (2006-07) NO LAW AT CAGR NO LAW (201112) 1 AGROTECH 417.77 8 613.84 8 613.84 2 BUILDTECH 1415.43 15 2846.94 15 2846.94 3 CLOTHTECH 7988.73 12 14078.87 12 14078.87 4 GEOTECH 1688.91 15 3397.00 68.98 23269.28 5 HOMETECH 1628.74 16 3420.91 16 3420.91 6 INDUTECH 1253.35 12 2208.83 12 2208.83 7 MOBILTECH 1613.53 15 3245.39 15 3245.39 8 MEDTECH 1280.32 12 2256.36 20 3185.85 9 OEKOTECH 69.91 12 123.21 68.17 940.33 10 PACKTECH 5785.93 20 14397.25 20 14397.25 11 PROTECH 1027.11 17 2251.89 25.45 3191.32 12 SPORTTECH 1906.36 12 3359.66 12 3359.66 TOTAL 26076.09 14.94 24.57 74758.46 19 Mar 2010 52200.13 WITH WITH LAW AT LAW(2011CAGR 12) textile policy of government of india recognised growth prospects of technical textiles and accords priority for their development constitution of expert committee on technical textiles (ectt) setting up of a steering committee on growth and development of technical textiles (scgdtt) government launched technology mission on technical textiles in the xi th five year plan to identify major constraints for improving their production and consumption in india baseline survey on technical textiles was conducted 19 Mar 2010 identified agrotech, protech, geotech & buildtech and medtech as key areas for growth and development in india coverage of technical textiles under technology upgradation fund scheme (tufs) setting up of 12 excellence centres (ecs) for technical textiles – already started ecs for geotech & buildtech; agrotech; medtech; and protech de-reservation of sanitary napkins / baby diapers basic custom duty for major machineries on technical textiles reduced from 10 to 5 % 10 % capital subsidy for new projects 5 % interest subsidy on loans under tufs 14 special economic zones to attract fdi and duty free imports and domestic procurement for 100 % exports gujarat state is providing 10 % investment subsidy on technical textile projects 19 Mar 2010 application areas identification of application areas having strong potential 19 Mar 2010 in the domestic market i.e geotech (including buildtech), medtech, agrotech, protech and mobiltech initial selection of products for which technical know-how, production facilities and raw materials already exist indigenization of value added products of relatively easier technology capable of quick assimilation development of technical textiles in high tech applications of aerospace, defence, etc. with public/private initiatives, joint ventures with mncs urgent quality standards for identified products and their installation raw material use of indegeneously available fibres and import of high performance fibres fibres (natural or man-made) use based on durability, survivability and integrity requirements considering health, safety and environmental impacts providing fiscal incentives to specialty fibres to make them cost competitive and easilt affordable amending existing regulation (drugs & cosmetics act) to cover newly developed manmade fibre products e.g. antimicrobial fibres, super absorbant fibres, non toxic/non allergic fibres, breathable fibres, antistatic fibres, etc. 19 Mar 2010 THRUST NEEDED FOR SPECIALTY FIBRES 19 Mar 2010 NEED FOR LONG LASTING PERFORMANCE PROPERTIES COMPATIBILITY, DURABILITY, STRUCTURAL INTEGRITY AND SURVIVABILITY UNIFORMITY OF PROPERTIES IN ALL DIRECTIONS THE STANDARDS NORMALLY COVER LONG TERM DURABILITY WHICH IS NOT PROVIDED BY OTHER FIBRES AS PER STANDARDS, THE PERFORMANCE AND FUNCTIONAL CHARACTERISTICS MUST BE CONTROLLED WITHIN NARROW LIMITS (AVERAGE VALUE + 2 X STANDARD DEVIATION) TO HAVE UNIFORMITY IN ALL DIRECTIONS TO PREVENT THEIR FUNCTIONAL FAILURE manufacturing facilities re-orientation of production facilities and training of 19 Mar 2010 manpower products which can be manufactured on existing machinery be identified and marketing efforts be made incentives for state of the art machinery for high potential high tech products developing proper product-mix capacity building of raw materials, machinery, infrastructure and production r&d and quality assurance investment in r&d and quality management as well as product development needed latest world class testing facilities needed national standards at par with international developments needed on urgent basis especially for specifications of products and codes of practices for installation, use and maintenance of technical textile products certification and accreditation of testing facilities and production as per international standards 19 Mar 2010 domestic and export market development of technical textiles regulatory framework in the interest of environment, 19 Mar 2010 health and safety assistance for international / national exhibitions, fairs, seminars, etc. incentives for certification / accreditation to international standards incentives for substitution of traditional textiles by technical textiles mandatory use of geotech, buildtech medtech for health, safety, environment and efficient utilisation of public funds mandatory use of fr textiles in public places, buildings, uniform fabrics, etc. in case of geotech / buildtech projects, the approval and implementation should include design parameters also and the priciple used should be f – d—b—o--t: finance design build operate transfer fiscal measures such as reduction of excise/custom duty/sales tax/service tax 19 Mar 2010 considerable reduction of cost of projects (materials, design, installation and evaluation) minimum subsequent repairs / maintenance; prevention of environmental pollution leading to sustainable development most efficient utilization of resources better designs and longer project service life increased safety of life and property alternate and best technological applications for a specific end use 19 Mar 2010 geotech 19 Mar 2010 geotextiles and geogrids for reinforcement of base and subbase in pavement structures geotextiles for subsurface drainage, subgrade separation and stabilisation, protection (cushioning), permanent erosion control, pavement overl;ays, slope protection and silt fence geotextiles for sediment control geosynthetic clay liners gabions for prevention of soil erosion geogrids for mse systems geosynthetic mats geonets and geocomposites for waste containment geocomposites / geocells / geomembranes / geofoams prefabricated geosynthetic edge and vertical drains geosynthetics for waste containment BUILDTECH geo-membranes for waterproofing of roofs controlled permeability textiles for concrete formwork lining fibers for reinforceed concrete synthetic fibre insulation blanket reflective vapour breathable textile substrate as radiant barrier in building envelope house wraps vapor breathable textile substrate as mineral wool insulation facing for buildings technical textiles as honeycombs for landscaping architectural fabric/ tensile structures (temporary and permanent) hoardings for buildings 19 Mar 2010 protect 19 Mar 2010 bullet proof fabric/jacket protective clothing for agricultural workers protective clothing for mechanical /chemical / nuclear / biological protection hi-visibility / high altitude warning clothing protective clothing for dust protection protective clothing for acoustic protection protective clothing for biological protection protective clothing for electric arc welding fire retardant upholstery, curtains, bednets, beddings, uniform fabrics, bed linens, etc. Agrotech 19 Mar 2010 crop covers greenhouse covers row covers poly-house films/membranes shade-nets mulch mats baler twines polyester/pp/hdpe nets for fishing waterproof lining Meditech extracorporeal devices artificial kidney, liver, lung, heart pacer non-implantable textile materials absorbent pad, bandages, compression bandages, plasters, absorbent gauges, lint and wadding implantable textile materials tendons, ligaments, cartilage, skin, contact lenses, cornea, joints, vascular grafts, heart valves healthcare and hygiene products surgical gowns, caps, gloves , masks; surgical covers drapes, aprons; beddings (blankets, sheets, pillow covers); clothing (uniform); incontinence/baby/adult diapers; cloth wiper, surgical hosiery, sanitary napkins, medical mattress, sterilization wraps, head and shoe covers, panty shield, wadding; wipes 19 Mar 2010 other technical textiles hometech (fiberfill, blinds, stuffed toys, carpet backing fabric) mobiltech (seat belts, exhaust filters, airbags, tyre cord fabric, seat cover, headliners, insulation felts, interior carpets) packtech (flexible intermediate bulk containers, soft luggage products, sackings) indutech (synthetic tarpaulins, awnings, tents, conveyor belts, hoses, ropes, cordages, drive belts, webbings, slings, tapes, computer ribbons, battery separators, industrial filters) sporttech (sports nets, sports footwear, sports composites, sleeping bags, artificial turfs, ballooning fabric, parachute fabric) clothtech (sewing threads, interlinings, zip fasteners, tapes, velcro) oekotech (environmental control-bags/filters, municipal wates – geosynthetics) 19 Mar 2010 THANK YOU 19 Mar 2010