Thermophilic anaerobic co-digestion of agro-waste and

advertisement

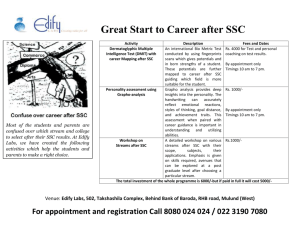

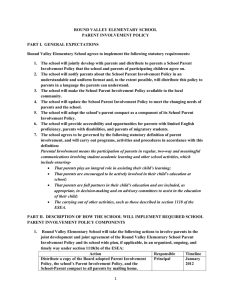

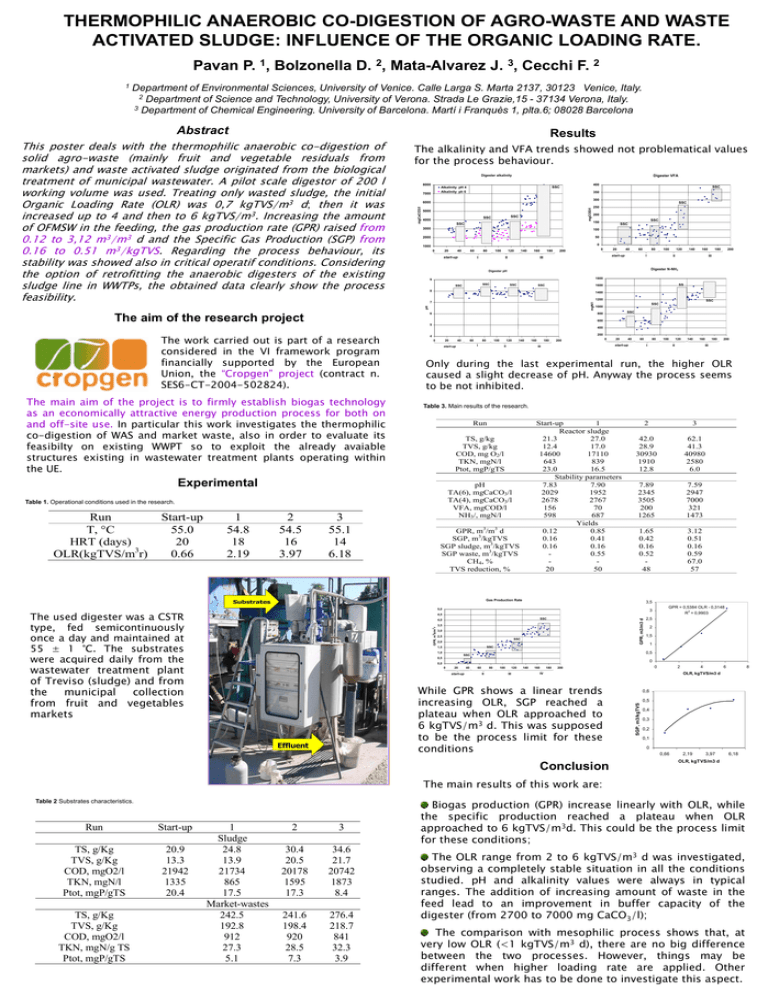

THERMOPHILIC ANAEROBIC CO-DIGESTION OF AGRO-WASTE AND WASTE ACTIVATED SLUDGE: INFLUENCE OF THE ORGANIC LOADING RATE. Pavan P. 1, Bolzonella D. 2, Mata-Alvarez J. 3, Cecchi F. 2 1 Department of Environmental Sciences, University of Venice. Calle Larga S. Marta 2137, 30123 Venice, Italy. 2 Department of Science and Technology, University of Verona. Strada Le Grazie,15 - 37134 Verona, Italy. 3 Department of Chemical Engineering. University of Barcelona. Martí i Franquès 1, plta.6; 08028 Barcelona Abstract The alkalinity and VFA trends showed not problematical values for the process behaviour. Digester alkalinity 8000 Digester VFA SSC 350 300 mgCOD/l 6000 5000 SSC SSC 4000 SSC 200 2000 50 1000 0 20 40 60 start-up 80 100 120 I 140 160 180 SSC 150 100 0 SSC 250 3000 SSC 0 200 20 40 60 80 start-up III II 100 I 120 140 160 II 180 200 III Digester N-NH3 Digester pH 1800 9 SSC SSC SSC SS C 1600 SSC 8 1400 1200 pH mgN/l 7 6 The aim of the research project 400 SSC Alkalinity pH 4 Alkalinity ph 6 7000 mgCaCO3/l This poster deals with the thermophilic anaerobic co-digestion of solid agro-waste (mainly fruit and vegetable residuals from markets) and waste activated sludge originated from the biological treatment of municipal wastewater. A pilot scale digestor of 200 l working volume was used. Treating only wasted sludge, the initial Organic Loading Rate (OLR) was 0,7 kgTVS/m3 d; then it was increased up to 4 and then to 6 kgTVS/m3. Increasing the amount of OFMSW in the feeding, the gas production rate (GPR) raised from 0.12 to 3,12 m3/m3 d and the Specific Gas Production (SGP) from 0.16 to 0.51 m3/kgTVS. Regarding the process behaviour, its stability was showed also in critical operatif conditions. Considering the option of retrofitting the anaerobic digesters of the existing sludge line in WWTPs, the obtained data clearly show the process feasibility. Results SSC SSC 1000 SSC 800 600 5 400 The work carried out is part of a research considered in the VI framework program financially supported by the European Union, the “Cropgen” project (contract n. SES6-CT-2004-502824). The main aim of the project is to firmly establish biogas technology as an economically attractive energy production process for both on and off-site use. In particular this work investigates the thermophilic co-digestion of WAS and market waste, also in order to evaluate its feasibilty on existing WWPT so to exploit the already avaiable structures existing in wastewater treatment plants operating within the UE. 200 4 0 20 1 54.8 18 2.19 2 54.5 16 3.97 80 100 I 120 140 II 160 180 200 0 20 40 60 start-up III 80 Run Start-up 1 Reactor sludge 21.3 27.0 12.4 17.0 14600 17110 643 839 23.0 16.5 Stability parameters 7.83 7.90 2029 1952 2678 2767 156 70 598 687 Yields 0.12 0.85 0.16 0.41 0.16 0.16 0.55 20 50 TS, g/kg TVS, g/kg COD, mg O2/l TKN, mgN/l Ptot, mgP/gTS pH TA(6), mgCaCO3/l TA(4), mgCaCO3/l VFA, mgCOD/l NH3/, mgN/l GPR, m3/m3 d SGP, m3/kgTVS SGP sludge, m3/kgTVS SGP waste, m3/kgTVS CH4, % TVS reduction, % Substrates 140 160 180 200 III 2 3 42.0 28.9 30930 1910 12.8 62.1 41.3 40980 2580 6.0 7.89 2345 3505 200 1265 7.59 2947 7000 321 1473 1.65 0.42 0.16 0.52 48 3.12 0.51 0.16 0.59 67.0 57 Gas Production Rate 3,5 5,0 GPR = 0,5384 OLR - 0,3148 R2 = 0,9903 3 4,5 GPR, m3/m3 d SSC 4,0 3 3 GPR, m b/m r 3,5 3,0 2,5 SSC 2,0 2,5 2 1,5 1 SSC 1,5 1,0 0,5 SSC 0,5 0 0,0 20 start-up 40 60 80 II 100 120 III 140 160 180 0 200 2 While GPR shows a linear trends increasing OLR, SGP reached a plateau when OLR approached to 6 kgTVS/m3 d. This was supposed to be the process limit for these conditions Conclusion 4 6 8 OLR, kgTVS/m3 d IV 0,6 0,5 SGP, m3/kgTVS 0 Effluent 120 II Table 3. Main results of the research. 3 55.1 14 6.18 The used digester was a CSTR type, fed semicontinuously once a day and maintained at 55 ± 1 °C. The substrates were acquired daily from the wastewater treatment plant of Treviso (sludge) and from the municipal collection from fruit and vegetables markets 100 I Only during the last experimental run, the higher OLR caused a slight decrease of pH. Anyway the process seems to be not inhibited. Table 1. Operational conditions used in the research. Start-up 55.0 20 0.66 60 start-up Experimental Run T, °C HRT (days) OLR(kgTVS/m3r) 40 0,4 0,3 0,2 0,1 0 0,66 2,19 3,97 6,18 OLR, kgTVS/m3 d The main results of this work are: Table 2 Substrates characteristics. Run Start-up TS, g/Kg TVS, g/Kg COD, mgO2/l TKN, mgN/l Ptot, mgP/gTS 20.9 13.3 21942 1335 20.4 TS, g/Kg TVS, g/Kg COD, mgO2/l TKN, mgN/g TS Ptot, mgP/gTS 1 Sludge 24.8 13.9 21734 865 17.5 Market-wastes 242.5 192.8 912 27.3 5.1 2 3 30.4 20.5 20178 1595 17.3 34.6 21.7 20742 1873 8.4 241.6 198.4 920 28.5 7.3 276.4 218.7 841 32.3 3.9 Biogas production (GPR) increase linearly with OLR, while the specific production reached a plateau when OLR approached to 6 kgTVS/m3d. This could be the process limit for these conditions; The OLR range from 2 to 6 kgTVS/m3 d was investigated, observing a completely stable situation in all the conditions studied. pH and alkalinity values were always in typical ranges. The addition of increasing amount of waste in the feed lead to an improvement in buffer capacity of the digester (from 2700 to 7000 mg CaCO3/l); The comparison with mesophilic process shows that, at very low OLR (<1 kgTVS/m3 d), there are no big difference between the two processes. However, things may be different when higher loading rate are applied. Other experimental work has to be done to investigate this aspect.