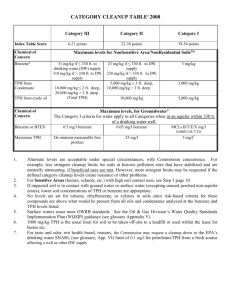

Hydrocarbon Converter - enviro products international

DISTRIBUTED BY

A non-toxic, Planet Friendly solution for soil remediation

Environmental cleanup:

Proven effective in the field with documented test results

Proven superior in eliminating TPH contamination caused by oil spills and fuel oil leakage

Effective in treating large and small contaminate sites

No costly “dig and haul” methods that require soil removal and replacement

PROJECT CASE STUDY

Location: South Louisiana

Project: Drill Yard Site Remediation

Contaminate: Petroleum Hydrocarbons 490 cubic yards of soil

Initial TPH Levels Prior To Treatment: 6,000 ppm

TPH Levels After Treatment : 10 ppm after 12 days

***Louisiana Department of Environmental Quality declared the site clear after testing on the 12 th day. Est. cost savings $122/yd

BEFORE TREATMENT

AFTER TREATMENT

BEFORE

Proven Field Results

AFTER

A non-toxic, planet friendly solution for soil remediation

•

Frelo Hydrocarbon Converter is a specifically blended silicate based liquid that reduces hydrocarbons >98% upon contact when applied to impacted soils, surface and groundwater.

•

A minimal reaction time renders the contaminant irreversibly altered

TESTED AND APPROVED FOR USE BY THE

NIGERIAN GOVERNMENT

BEFORE TREATMENT

AFTER TREATMENT

BEFORE

Proven Field Results

AFTER

A non-toxic, planet friendly solution for soil remediation

Observe and Test The Difference of Frelo’s Hydrocarbon Converter

• Unlike some of the present methods, surfactants and fertilizer, the Frelo Hydrocarbon Converter actually changes the composition of the hydrocarbons rather than just breaking them down as a surfactant would do into smaller particles and then using a fertilizer to make the grass grow but still leaving the hydrocarbons intact to eventually dissipate over time.

DISTRIBUTED BY

PROJECT CASE STUDY

Location: Kirby, Arkansas

Project: Diesel Spill on land and water.

Contaminate: 300 gallons of diesel fuel migrated approx. 450 yards across a parking lot, pasture land, and into a farm pond

Initial TPH Levels Prior To Treatment: 15,400 ppm

TPH Levels After Treatment : 40.4 ppm after 72 hours

***Arkansas Dept. of Environmental Quality, Army Corps of

Engineers, and Pike County Office of Emergency Services surveyed the area after cleanup and declared the site clear.

A non-toxic, planet friendly solution for soil remediation

Observe and Test the Difference of Frelo’s Hydrocarbon Converter

FRELO HYDROCARBON CONVERTER typically works much faster than typical remediation procedures. The catalytic conversion process begins upon the drying of the FRELO

HYDROCARBON CONVERTER.

The sodium silicate attaches to the weak hydrocarbon molecule. Also, FRELO HYDROCARBON

CONVERTER is not corrosive and contains biodegradable ingredients and actually helps acidic soil by raising the pH and thus allowing natural organisms to work in the soil.

BEFORE TREATMENT

AFTER TREATMENT

BEFORE

Proven Field Results

AFTER

A non-toxic, planet friendly solution for soil remediation

Compare the Benefits of Frelo Technology

• Frelo Hydrocarbon Converter does not add hazardous ingredients to the soil and/or water matrix.

• Unlike microbes, Frelo Hydrocarbon converter is not dependent upon soil type and you are not adding new microbes to the the environment.

• Results can actually be noticed in as little as 72 hours depending upon weather conditions.

DISTRIBUTED BY

PROJECT CASE STUDY

Location: California North Coast

Project: Gasoline on soil

Contaminate: 1,915 cubic yards of soil impacted from gasoline tank spill

Initial TPH Levels Prior To Treatment: 7,000 ppm

TPH Levels After Treatment : Non Detect after 14 days

A non-toxic, planet friendly solution for soil remediation

• Frelo Hydrocarbon Converter is non-corrosive to metal surfaces.

• Highly specialized equipment is not necessary to apply

Frelo Hydrocarbon Converter. People can be easily trained to apply Frelo Hydrocarbon Converter. It is not considered hazardous in terms of shipping and storage and is not flammable.

BEFORE TREATMENT

AFTER TREATMENT

BEFORE

Proven Field Results

AFTER

Proven science behind the product

• The breakdown of TPH (GRO, DRO) occurs upon direct contact of Frelo with the hydrocarbon contaminant.

• The process is described by leading chemist as a “catalytic conversion” and by the mechanism of dehydration of the hydrocarbon chain and a free substitution of the SiO radical in the presence of oxygen, the silicate molecule attaches to active sites on the hydrocarbon chain, converting the hydrocarbon to an organo-silicate residue.

DISTRIBUTED BY

BEFORE TREATMENT

AFTER TREATMENT

BEFORE

Proven Field Results

AFTER

PROJECT CASE STUDY

Location: Hot Springs, Arkansas

Project: Utility Vault

Contaminate: 300 Gallons of Gasoline and 2000 gallons of water in a concrete containment vault

Initial TPH Levels Prior To Treatment: 10,000 ppm

TPH Levels After Treatment : 34 ppm after 24 hours

***Arkansas Dept. of Environmental Quality declared the site clear afer 24 hours and the water was flushed in the city sewer.

BEFORE TREATMENT

AFTER TREATMENT

Proven Field Results

BEFORE AFTER

DISTRIBUTED BY

BEFORE TREATMENT

AFTER TREATMENT

BEFORE

Proven Field Results

AFTER

PROJECT CASE STUDY

Location: Haynesville, Louisiana

Project: Crude Oil Release on Soil

Contaminate: 400 gallons of crude oil washed approximately 100 yards after rain

Initial TPH Levels Prior To Treatment: Not Tested

TPH Levels After Treatment : < 100ppm within days

***Louisiana Department of Environmental Quality approved the area without having to haul any soil for remediation.